Connector assembly with shielded modules and method of making same

A technology of electrical connectors and modules, applied in the direction of two-part connection devices, parts of connection devices, connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

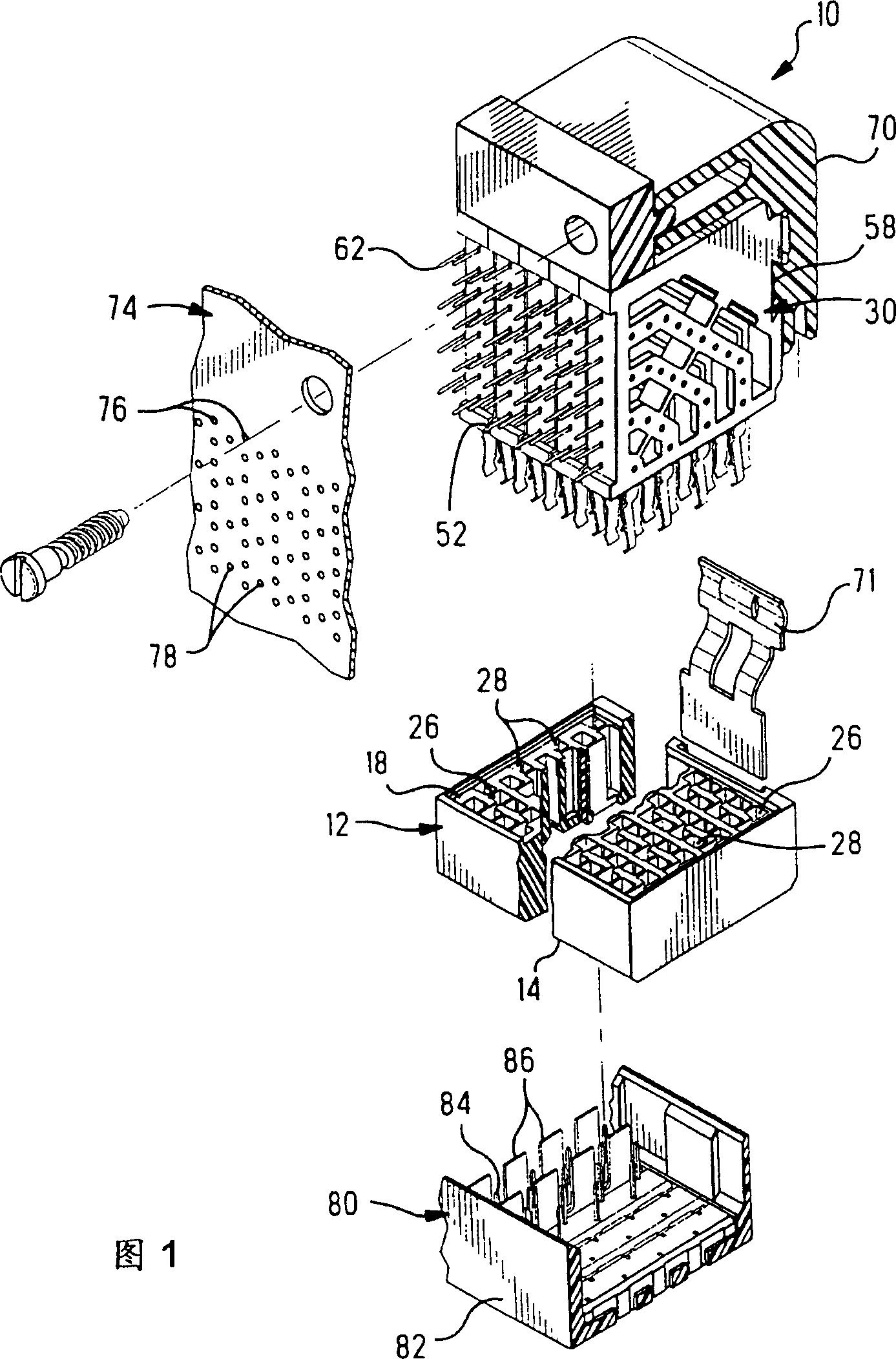

[0030] Figure 1 shows a connector 10 having a housing 12 and a plurality of shielded terminal modules 30 prepared in accordance with the present invention. The connector 10 is shown exploded from a circuit board or backplane 74 . The chassis 12 includes a mating surface 14 , a mounting surface 16 , a mounting surface 18 , a plurality of signal contact receiving channels 26 , and a plurality of ground contact receiving channels 28 extending from the mounting surface 18 to the mating surface 14 . The signal contact channel 26 includes an aperture 27 in the mating face 14 for receiving a complementary signal contact 84 of a mating connector 80 . The ground contact channel 28 includes a slot 29 in the mating face 14 for receiving a complementary ground contact 86 of the mating connector 80, such as Figure 6 and 7.

[0031] Mating connector 80 includes a housing 82 having a plurality of signal contacts 84 arranged in a staggered array complementary to the array of signal contacts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com