Piezoelectric ceramic composition

A technology of piezoelectric ceramics and compositions, applied in ceramics, circuits, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve problems such as inability to apply, inability to use sensors in products, and increase in mechanical quality factor Qm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

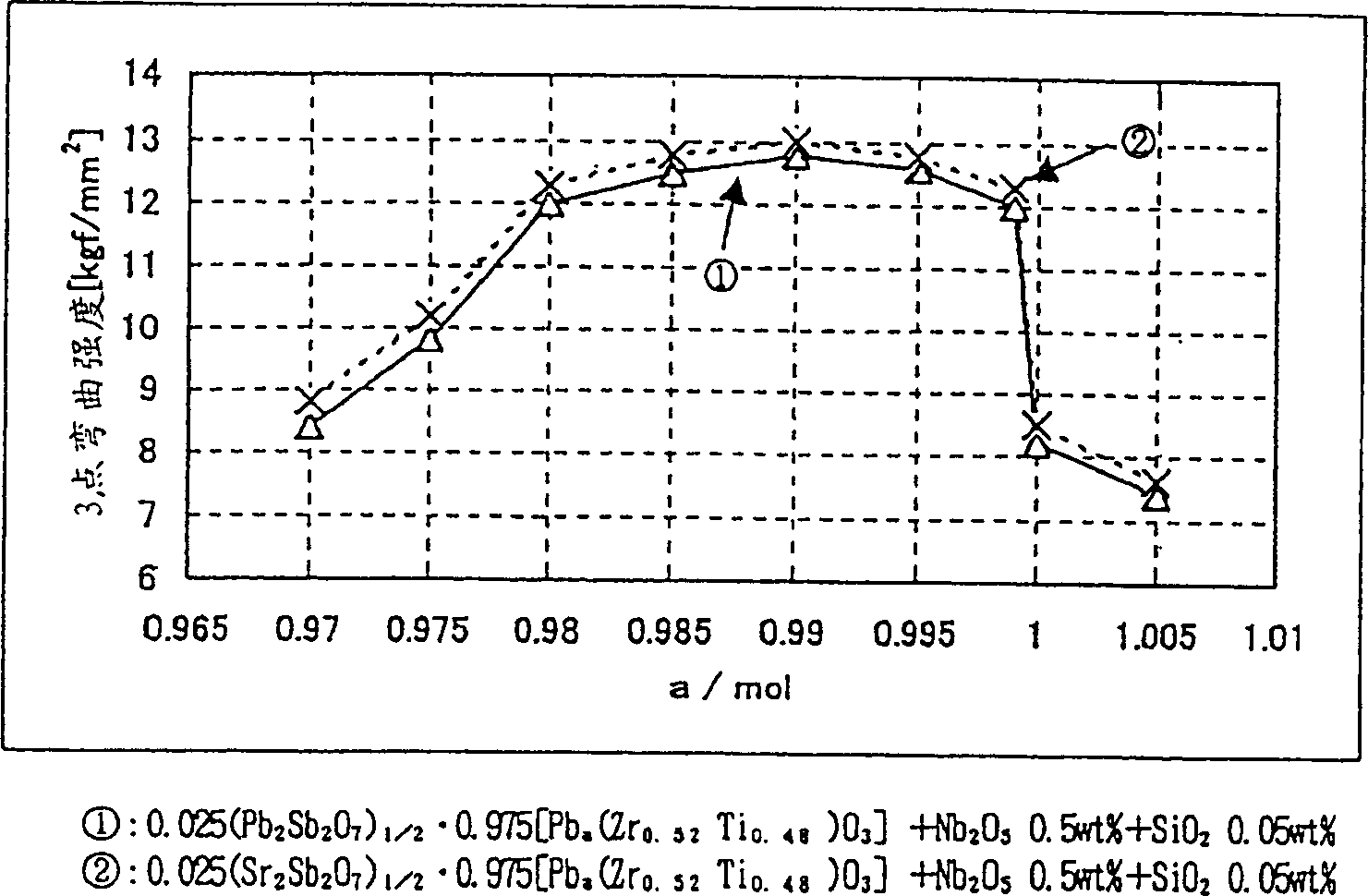

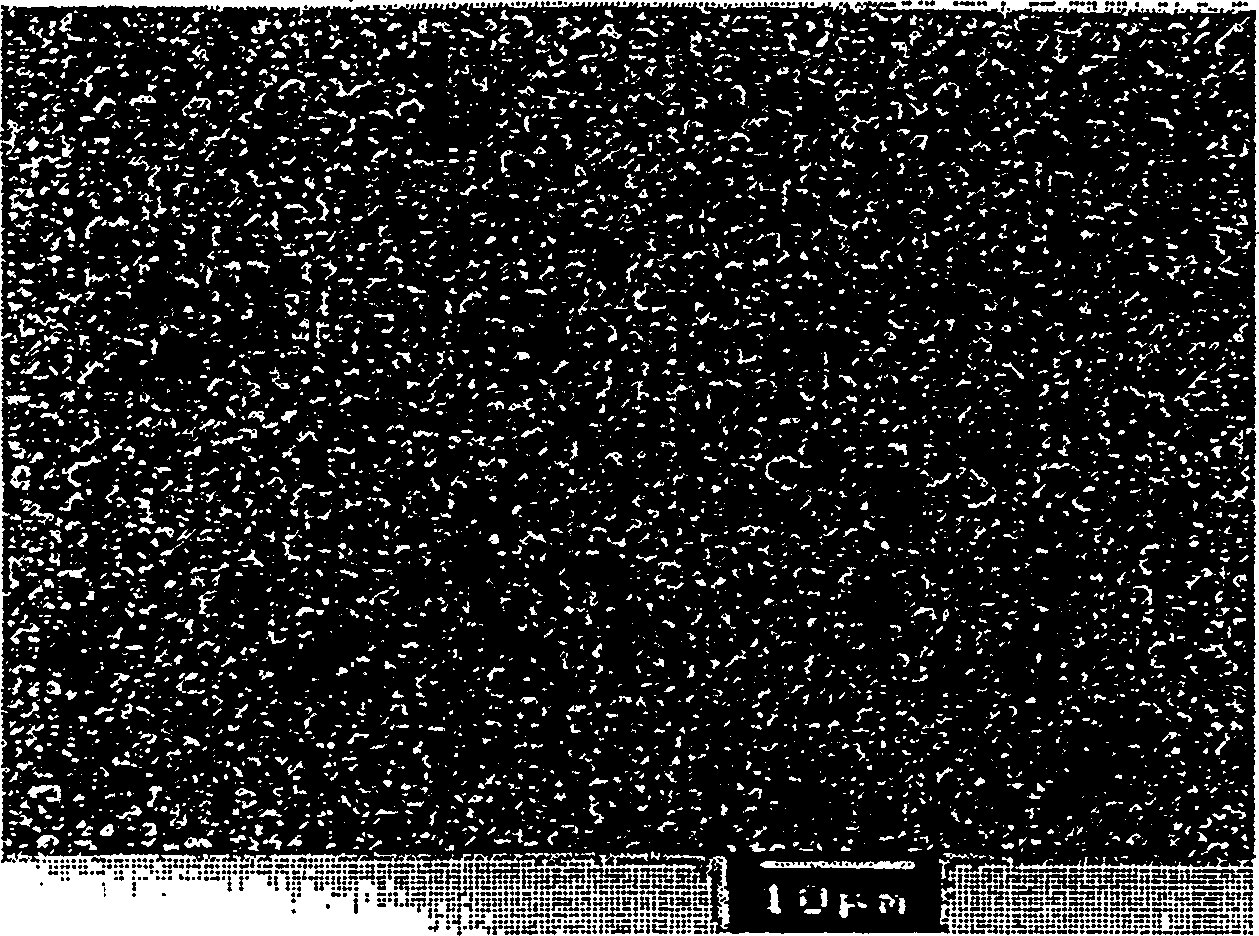

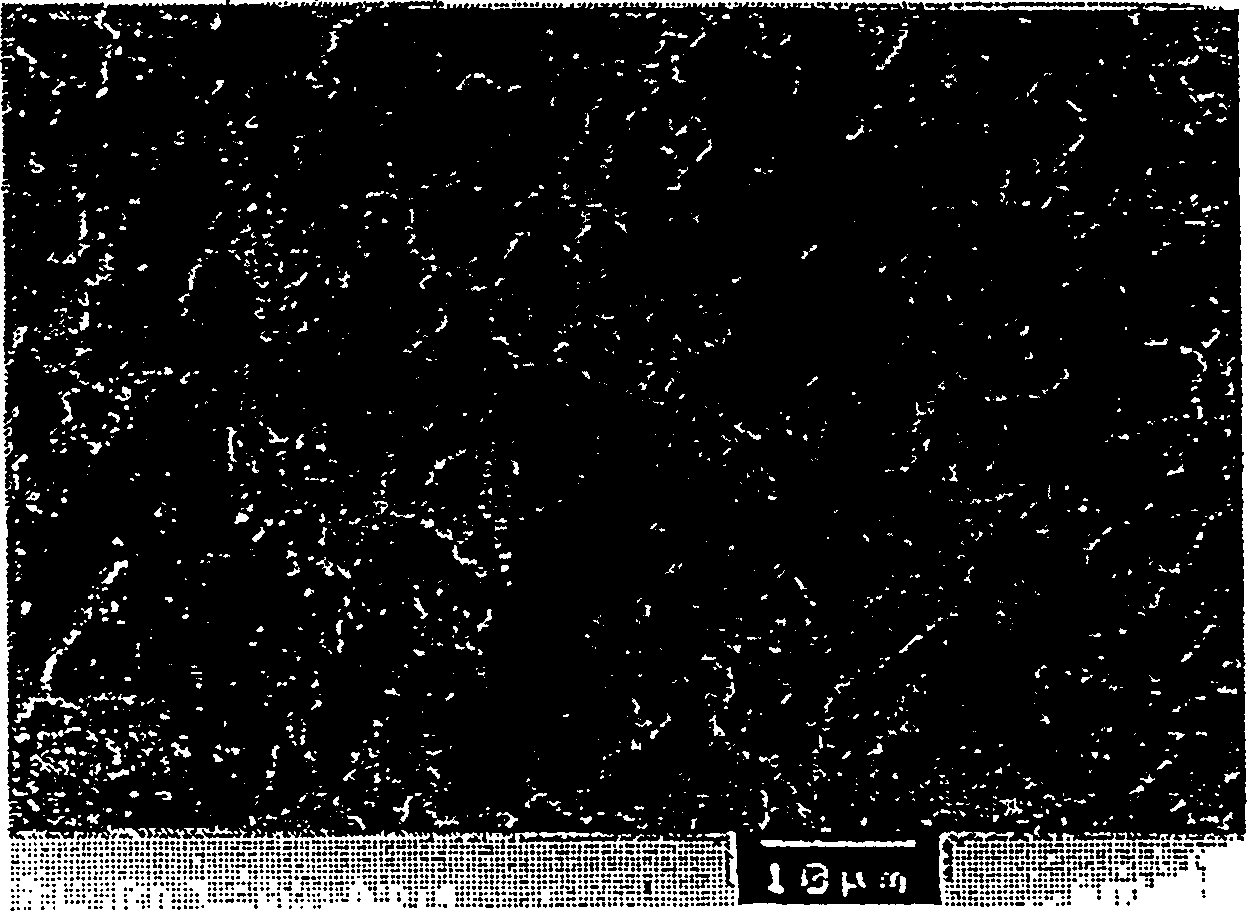

[0026] Examples of the present invention are described below.

[0027] Using chemically pure PbO, TiO 2 , ZrO 2 , Sb 2 o 5 , Nb 2 o 5 , Ta 2 o 5 , WO 3 , BaCO 3 , and SrCO 3 As starting materials, the components listed in Tables 1 and 2 were weighed and wet milled with a ball mill. Then, the mixed particles are calcined briefly at 850° C.-950° C. in air, and then wet-milled into powder using a ball mill.

[0028] Thereafter, the powder thus obtained was added with an organic binder and granulated at 2000 kg / cm 2 A disk-like structure with a diameter of 15 mm and a thickness of 1.5 mm was formed under pressure. The formed product is calcined at 1100°C-1240°C under atmospheric pressure.

[0029] The surface of the sintered product obtained above was ground to a thickness of 1.0 mm and processed to a diameter of 10 mm. Then, after forming the silver-fired electrodes, the sintered product was subjected to polarization treatment in the thickness direction for 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com