A cr-crn nanocomposite cermet coating and its preparation method and equipment

A metal-ceramic coating and nano-composite technology, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problem of no major breakthroughs, and achieve good interlayer bonding, good buffering effect, The effect of suppressing the growth of columnar crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

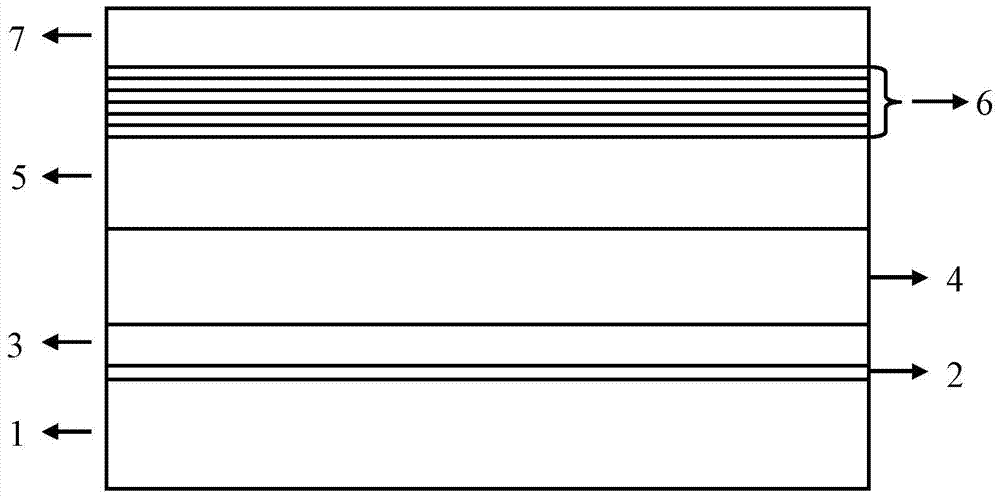

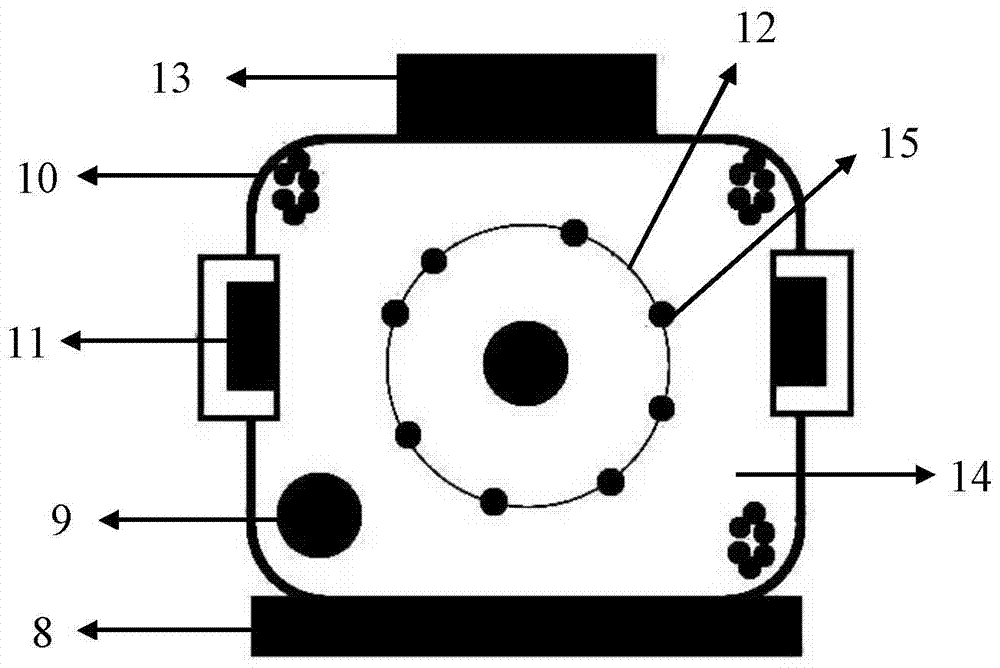

[0050] The stainless steel fasteners are fixed on the workpiece frame 12, and the workpiece frame 12 is rotated at a speed of 4 rad / min. Perform plasma cleaning on the fasteners at 100°C, -800V bias, and 2Pa argon environment for 60 minutes; then raise the temperature to 270°C and keep warm; turn on the arc target 11, and perform 2nm Cr under the conditions of 0.02Pa argon, -800V Diffusion layer preparation; turn off the arc target 11, turn on the tubular magnetron sputtering target 9, and use intermediate frequency magnetron sputtering to prepare a 5nm Cr bonding layer under the conditions of 0.4Pa argon and -500V; then reduce the substrate bias voltage, at 0.4Pa The 200nm Cr transition layer was prepared under the condition of argon and -50V; then nitrogen gas was gradually introduced, and the 200nm CrNx support layer was prepared under the condition of 0.4Pa pressure and -50V. Gas flow to maintain pressure balance; continue to maintain the pressure of 0.4Pa and -50V, and pr...

Embodiment 2

[0052] The stainless steel fasteners are fixed on the workpiece frame 12, and the workpiece frame 12 is rotated at a speed of 4 rad / min. Perform plasma cleaning on the fasteners at 450°C, -800V bias, and 2Pa argon environment for 30 minutes; then cool down to 250°C and keep warm; turn on the arc target 11, and perform 10nm Cr at 0.2Pa argon, -1000V conditions Diffusion layer preparation; turn off the arc target 11, turn on the tubular magnetron sputtering target 9, and use intermediate frequency magnetron sputtering to prepare a 100nm Cr bonding layer under the conditions of 1Pa argon and -1000V; then reduce the substrate bias, , -200V conditions for the preparation of 2000nm Cr transition layer; then nitrogen gas is gradually introduced, and the 1000nm CrNx support layer is prepared under the condition of 1Pa pressure and -250V. Pressure balance; continue to maintain the pressure of 1Pa and -250V, and prepare the Cr layer in the 5nm Cr / CrN anti-corrosion layer under the condi...

Embodiment 3

[0054] The stainless steel fasteners are fixed on the workpiece frame 12, and the workpiece frame 12 is rotated at a speed of 4 rad / min. Perform plasma cleaning on the fasteners at 350°C, -1000V bias, and 3Pa argon environment for 30 minutes; then cool down to 250°C and keep warm; turn on the arc target 11, and perform 9nm Cr at 0.15Pa argon, -1000V conditions Diffusion layer preparation; turn off the arc target 11, turn on the tubular magnetron sputtering target 9, and use intermediate frequency magnetron sputtering to prepare a 200nm Cr bonding layer under the conditions of 0.4Pa argon gas and -1000V; then reduce the substrate bias voltage, at 0.9Pa The 1000nm Cr transition layer was prepared under the condition of argon and -200V; then nitrogen gas was gradually introduced, and the 600nm CrNx support layer was prepared under the condition of 0.6Pa pressure and -250V. Gas flow to maintain pressure balance; maintain 0.4Pa pressure and -50V constant, prepare the Cr layer in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com