High-temperature high-hardness high-Nb-TiAl-Si alloy and preparation method thereof

A technology of nb-tial-si, high hardness, applied in high hardness and high Nb-TiAl-Si alloy and its preparation, high temperature field, can solve high Nb-TiAl alloy low room temperature plasticity, difficult preparation and processing, and limit industrial application process etc. to achieve high oxidation resistance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

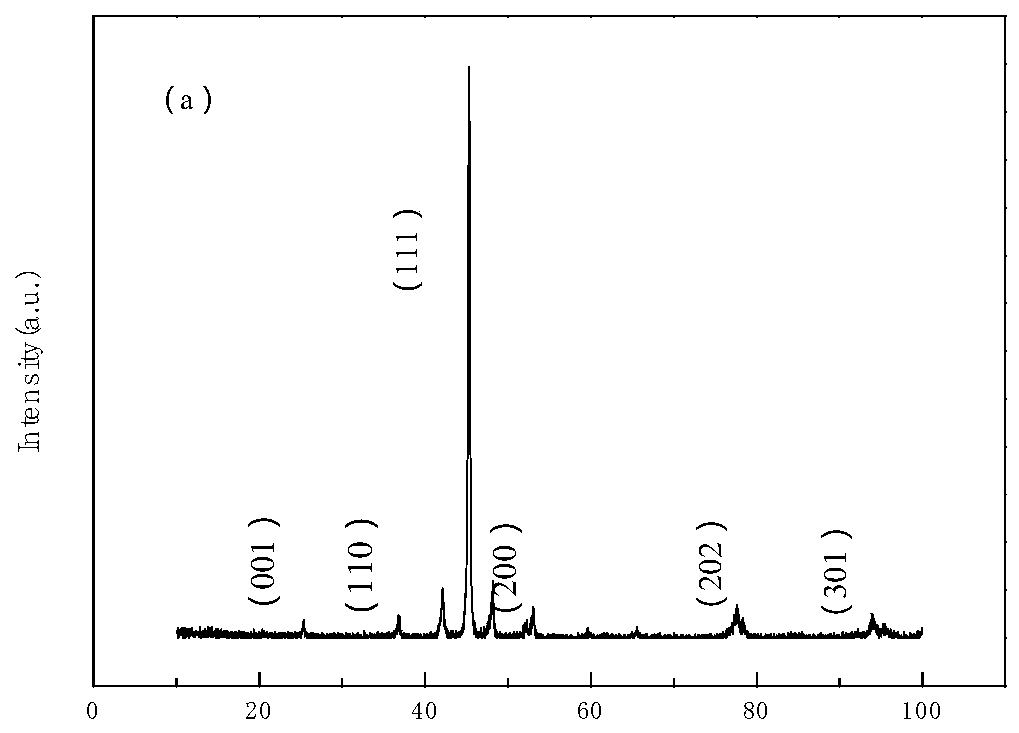

Image

Examples

Embodiment 1

[0025] The preparation method of the high Nb-TiAl-Si alloy of the present embodiment is prepared as follows: according to the atomic percentage, 49 parts of titanium sponge with a purity of 96.7%, 5 parts of 99.99% niobium powder, and 46 parts of 99.91% Al Blocks are used as raw materials, which are melted in a nitrogen protective atmosphere in a vacuum intermediate frequency induction melting furnace. Place the raw materials in the following order: first place the rare metal Nb powder, then place the Al block, and finally place the sponge Ti on the uppermost layer of the smelting furnace, and close the side furnace door. Before smelting, use mechanical pump and vacuum pump to evacuate to 1×10 -3 Pa, then filled with high nitrogen gas to 1000Pa. Start smelting, and control the smelting power to be 500Kw. In order to ensure the uniformity of the chemical composition of the ingot, each sample was turned and smelted six times. After smelting, the molten metal is poured into a ...

Embodiment 2

[0027] The preparation method of the high Nb-TiAl-Si alloy of the present embodiment is prepared according to the following method: get 48.9 parts of titanium sponge with a purity of 96.7%, 5 parts of 99.99% niobium powder, and 45.9 parts of 99.91% Al Block and 0.2 parts of Si are used as raw materials, which are smelted in a vacuum medium frequency induction melting furnace under a nitrogen protective atmosphere. Place the raw materials in the following order: first place the rare metal Nb powder, then place the Si and Al blocks, and finally place the sponge Ti on the uppermost layer of the smelting furnace, and close the side furnace door. Before smelting, use mechanical pump and vacuum pump to evacuate to 1×10 -3 Pa, then filled with high nitrogen gas to 1000Pa. Start smelting, and control the smelting power to be 500Kw. In order to ensure the uniformity of the chemical composition of the ingot, each sample was turned and smelted six times. After smelting, the molten met...

Embodiment 3

[0029] The difference between this embodiment and Embodiment 2 is that the alloy is heat treated at 950° C. for 10 hours. Others are identical with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com