Fortified artificial wetland sewage disposal method and system

A sewage treatment method and technology of sewage treatment system, which are applied in biological water/sewage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. Soil is easy to block and other problems, to achieve the effect of good hydraulic conductivity, saving operating costs and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

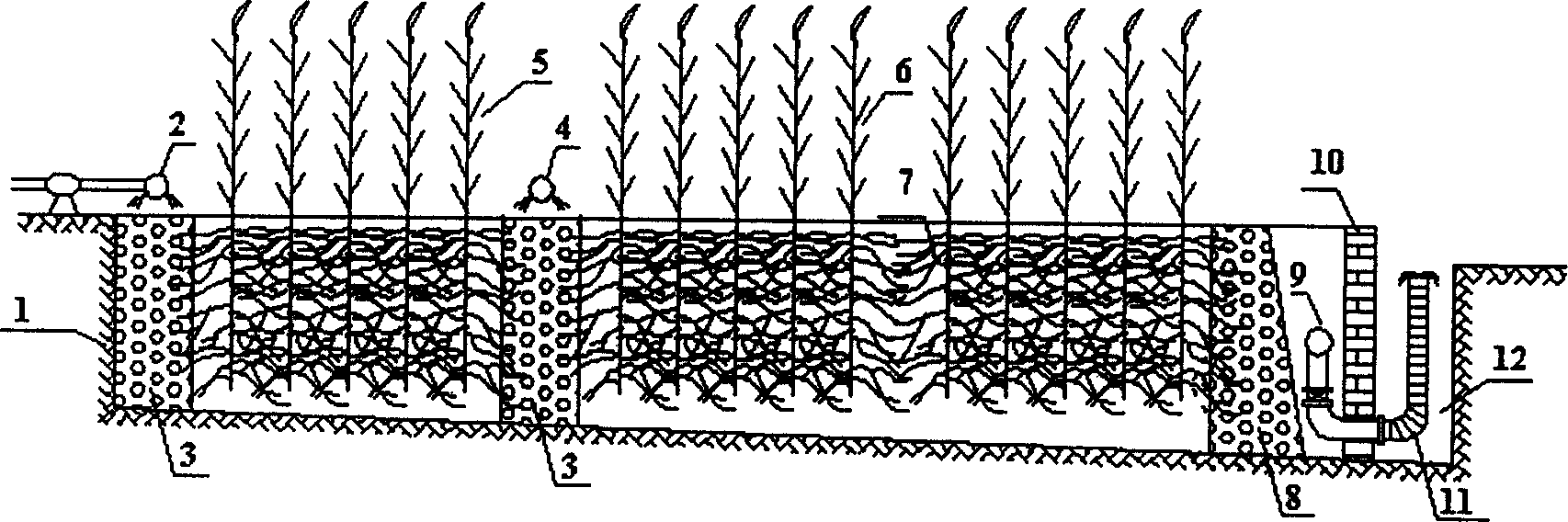

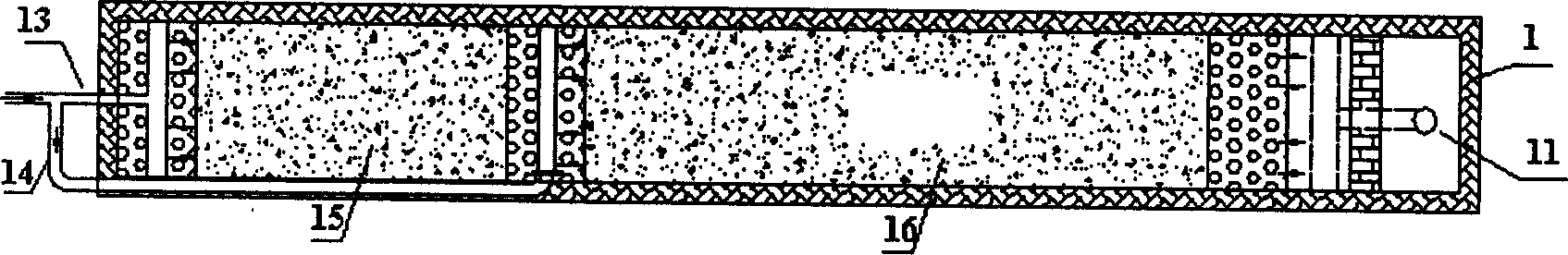

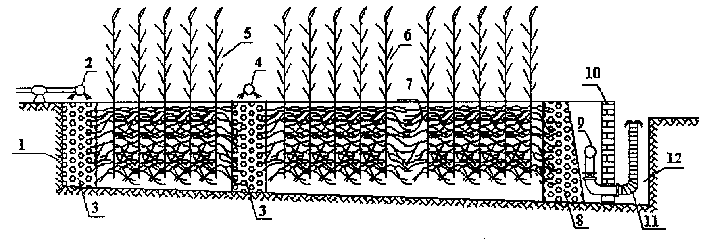

[0027] The composite filler in the constructed wetland system is prepared by mixing 85% slag, 10% red soil and 5% humus according to the volume ratio. The wetland area is 5m2, the depth is 60cm, and the slope is 0.5%. The first third section is planted with reeds, and the second third section is planted with Zizania sinensis. The water distribution pipe adopts a PVC pipe with a diameter of 25mm, and the holes are drilled at intervals along both sides of 90°, the hole spacing is 10cm, and the hole diameter is 2mm; the collecting pipe is a PVC pipe with a diameter of 50mm, and the holes are drilled at intervals along both sides of 90°, and the hole spacing is 10cm. , The aperture is 10mm. The diameter of the adjustable hose is 50mm. The stone water distribution area and water catchment area are filled with pebbles with a diameter of 30-60mm. The hydraulic load of the system is 4cm / d, and the sewage is fed in by continuous batching of sewage, and the proportion of sewage diversion at...

Embodiment 2

[0029]The composite filler in the constructed wetland system is prepared by mixing 50% slag, 30% red soil and 20% humus according to the volume ratio. The wetland area is 5m2, the depth is 80cm, and the slope is 1%. The first third section is planted with reeds, and the second third section is planted with water chestnuts. The water distribution pipe adopts a PVC pipe with a diameter of 25mm, and the holes are drilled at intervals along both sides of 90°, the hole spacing is 10cm, and the hole diameter is 5mm; the collecting pipe is a PVC pipe with a diameter of 50mm, and the holes are drilled at intervals along both sides of 90°, and the hole spacing is 10cm. , The aperture is 10mm. The diameter of the adjustable hose is 50mm. The stone water distribution area and water catchment area are filled with pebbles with a diameter of 30-60mm. In addition, a reference wetland is set up with the same structure and operating conditions, but the traditional filling method is used for the in...

Embodiment 3

[0031] The composite filler in the constructed wetland system is prepared by mixing 60% slag, 25% red soil and 15% humus according to the volume ratio. Wetland area is 5m 2 , The depth is 120cm, the slope is 2%, the first third section is planted with reeds, and the second third section is planted with Zizania. The water distribution pipe adopts a PVC pipe with a diameter of 25mm, and the holes are drilled at intervals along both sides of 90°, the hole spacing is 10cm, and the hole diameter is 5mm; the collecting pipe is a PVC pipe with a diameter of 50mm, and the holes are drilled at intervals along both sides of 90°, and the hole spacing is 10cm. , The aperture is 10mm. The diameter of the adjustable hose is 50mm. The stone water distribution area and water catchment area are filled with pebbles with a diameter of 30-60mm. In addition, a reference wetland is set up. The wetland structure and operating conditions are the same, but the internal filling is made of slag and general ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com