Efficient ecological waste water treating apparatus and method

An ecological treatment and waste water technology, applied in the direction of sustainable biological treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problems of small amount of sewage treatment, complex operation management, wetland plant death, etc., and achieve improvement Effects of effective volume, wide range of sources, and optimization of water collection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

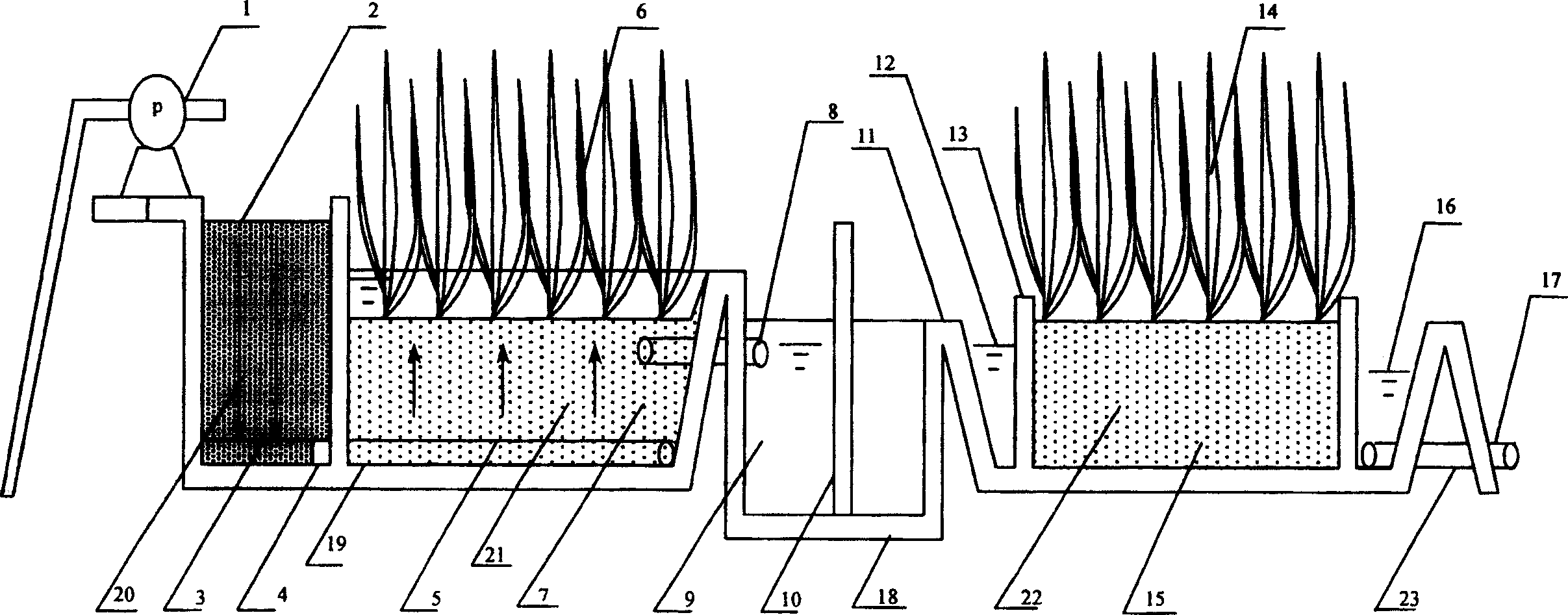

Embodiment 1

[0032] The filler in the gravel contact oxidation zone is mixed with 30% ash and 70% gravel by volume, the depth of the filler bed is 1.3m, and the backwash cycle is 30-60d; 50% of slag, 20% of gravel, 20% of zeolite, 5% of activated carbon, and 5% of humus are mixed and formulated to be effective. The depth of the packing bed is 100cm and 80cm respectively; the vertical upflow artificial wetland is planted with canna, red grass and golden leaf, The area ratio is 8:1:1, and reeds are planted in the horizontal flow artificial wetland; the water distribution pipe and the water collection pipe are UPVC pipes with a diameter of 25mm, and holes are drilled at intervals along both sides of 90 degrees, the hole spacing is 5cm, the hole diameter is 3mm, and the water collection pipe is 50mm The UPVC pipe is drilled at intervals along both sides of 90 degrees, the hole spacing is 10cm, and the hole diameter is 10mm. According to the total area, the hydraulic load rate of the system is ...

Embodiment 2

[0034] The filler in the inter-gravel contact oxidation zone is made of a mixture of 50% ash and 50% gravel by volume, the depth of the filler bed is 1.4m, and the backwash cycle is 30-60d; 55% of slag, 15% of gravel, 15% of zeolite, 10% of activated carbon, and 5% of humus are mixed and formulated to be effective. The depth of the packing bed is 110cm and 90cm respectively; the vertical upflow artificial wetland is planted with canna, red grass and golden leaf, The area ratio is 8:1:1, and reeds are planted in the horizontal flow artificial wetland; the water distribution pipe and the water collection pipe are UPVC pipes with a diameter of 25mm, and holes are drilled at intervals along both sides of 90 degrees, the hole spacing is 5cm, the hole diameter is 3mm, and the water collection pipe is 50mm The UPVC pipe is drilled at intervals along both sides of 90 degrees, the hole spacing is 10cm, and the hole diameter is 10mm. According to the total area, the hydraulic load rate ...

Embodiment 3

[0036] The filler in the inter-gravel contact oxidation zone is made of a mixture of 60% ash and 40% gravel by volume, the depth of the filler bed is 1.5m, and the backwash cycle is 30-60d; 60% of slag, 10% of gravel, 10% of zeolite, 15% of activated carbon, and 5% of humus are mixed and formulated to be effective. The depth of the packing bed is 120cm and 100cm respectively; the vertical upflow artificial wetland is planted with canna, red grass and golden leaf, The area ratio is 8:1:1, and reeds are planted in the horizontal flow artificial wetland; the water distribution pipe and the water collection pipe are UPVC pipes with a diameter of 25mm, and holes are drilled at intervals along both sides of 90 degrees, the hole spacing is 5cm, the hole diameter is 3mm, and the water collection pipe is 50mm The UPVC pipe is drilled at intervals along both sides of 90 degrees, the hole spacing is 10cm, and the hole diameter is 10mm. According to the total area, the hydraulic load rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com