Manufacturing method of lead acid battery electrode plate grid and its equipment

A technology of lead-acid battery and manufacturing method, applied in the direction of electrode carrier/collector, etc., can solve the problems of high lead consumption, poor uniformity, large surface density error, etc., and achieve the effect of saving wastewater treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

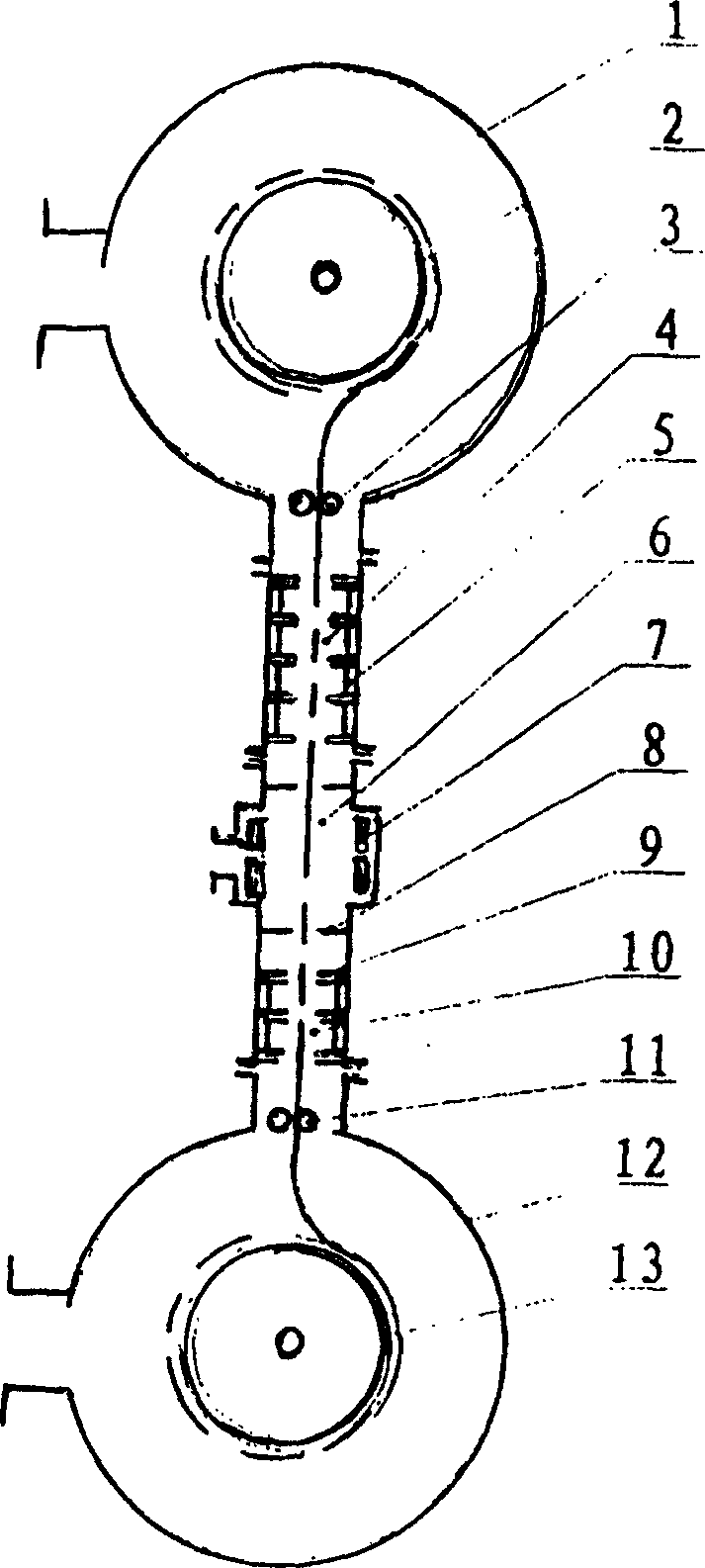

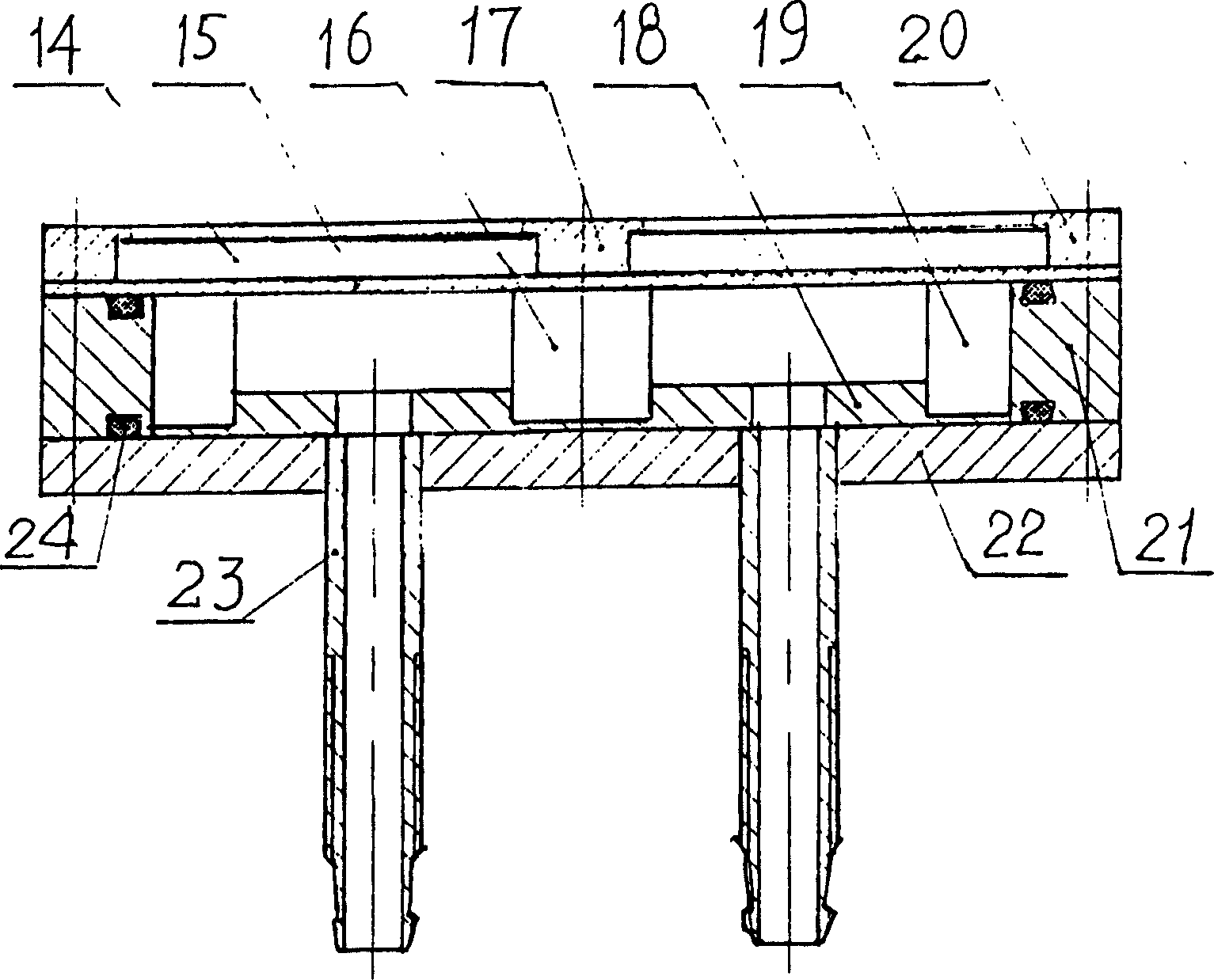

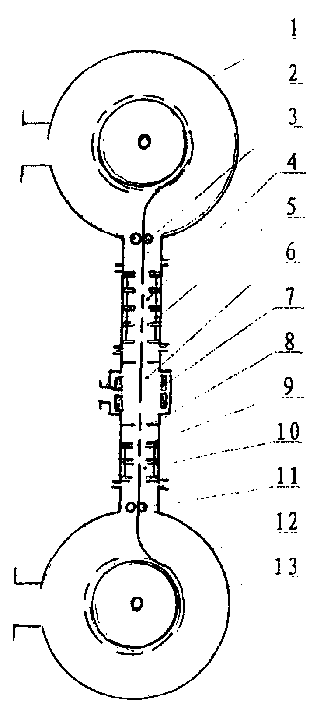

[0073] The present invention adopts the combined process technology of "physical vapor deposition-electrodeposition-heat treatment", adopts the patented technology and special equipment for continuous production of strip-shaped non-metallic materials, and manufactures continuous and uniform lead cloth grids. Since the system is equipped with an online control surface density The device can precisely control the mass density of lead or lead alloy in the optimal range. Surface density error ≤ ± 30g / m, which is conducive to ensuring the consistency of electrode and battery performance. The lead consumption of the grid is reduced, and the weight specific energy of the battery is increased. The combined technology of "Physical Vapor Deposition (PVD)-Electrodeposition-Heat Treatment" is used to prepare continuous and uniform lead-cloth battery grids with an amplitude of 0.3-1.2m and a continuous length of 2-300m. Or a sheet-like lead cloth grid with a width of 0.3-1.2m and a length...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com