Method for guiding are by laser, and are guiding welding and device by the method

A welding method and welding equipment technology, applied in laser welding equipment, arc welding equipment, welding equipment, etc., can solve problems such as hard-to-inductive arcs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Embodiments of the present invention will be described below with reference to the drawings.

[0066] First, the principle of the present invention will be explained.

[0067] The arc induction phenomenon by laser is the phenomenon of floating (pul-mu) composed of ionized metal vapor and thermal electrons in the laser irradiation part by laser irradiation. Compared with the air in the basic insulating state, due to the occurrence of this floating , the impedance between the torch electrode and the laser irradiated part of the base metal will decrease, and at the same time, the part of the base metal irradiated by the laser will be heated to release thermal electrons, so an arc discharge will be induced in the laser irradiated part.

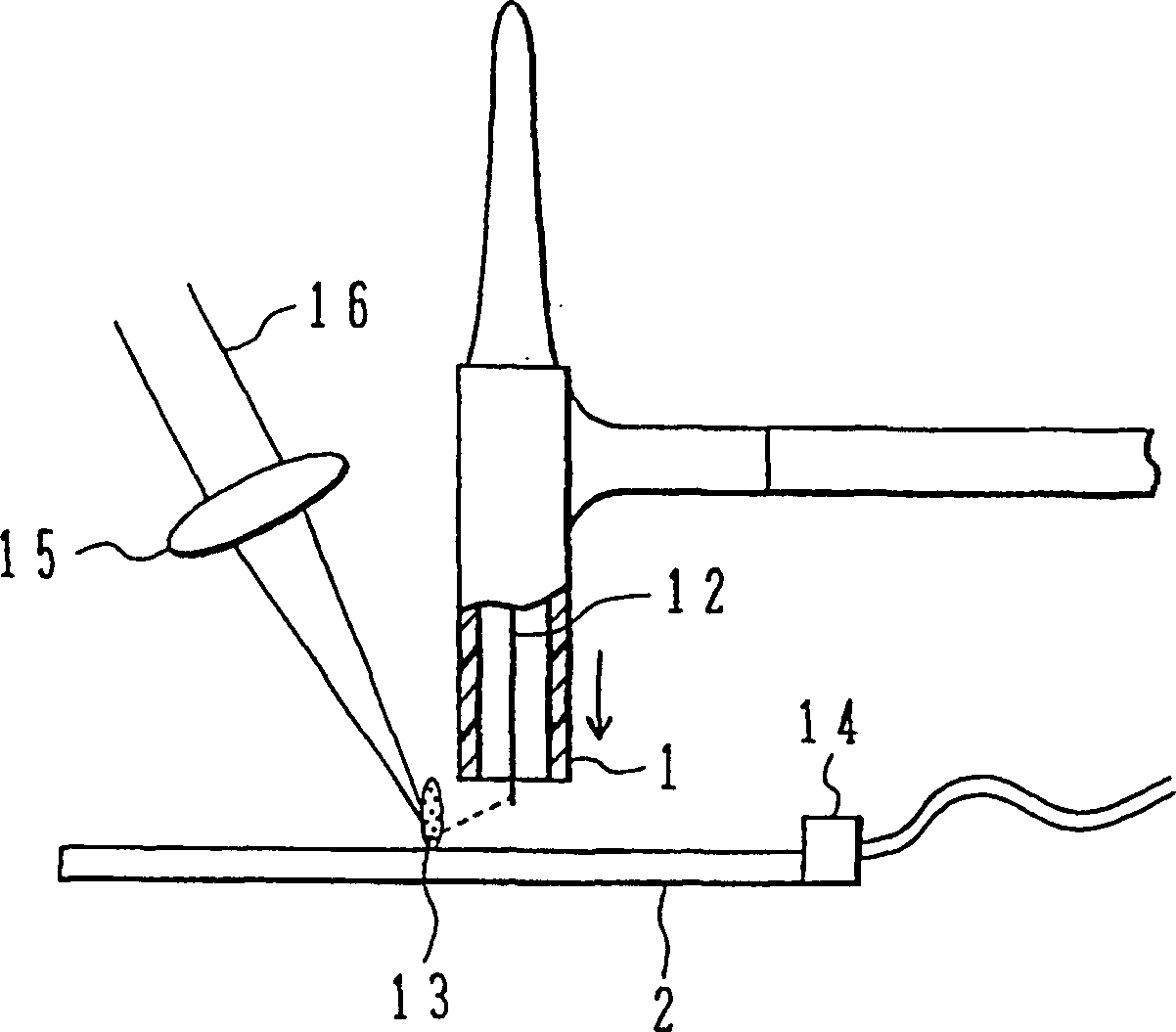

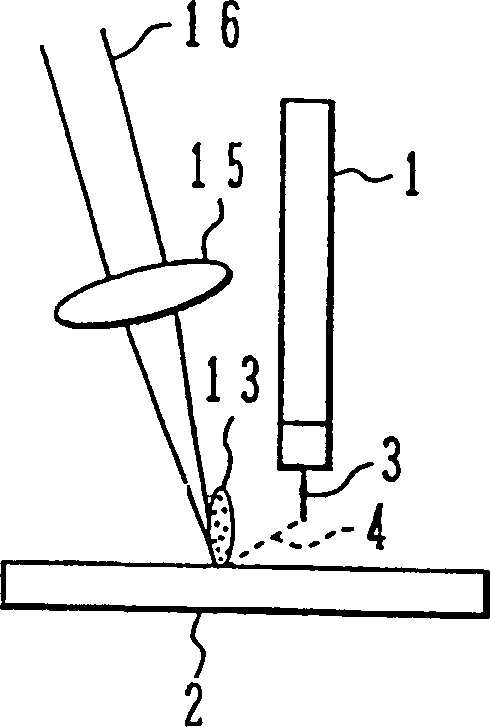

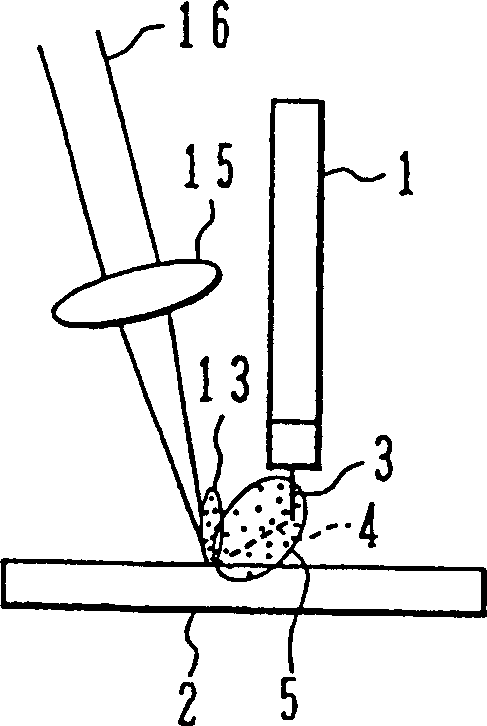

[0068] Fig. 1 illustrates the principle of the present invention by taking the induction of arc discharge in TIG welding as an example.

[0069] In FIG. 1 , a welding torch 1 is a torch for TIG welding, and an alternating voltage or a puls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com