Processor of pulse electric field sterilizing equipment

A technology of sterilization equipment and pulsed electric field, which is applied in the field of processors, can solve the problems of no pretreatment device, no prepolarization device, and inapplicability, and achieve the effects of improved treatment effect, strong electric field strength, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

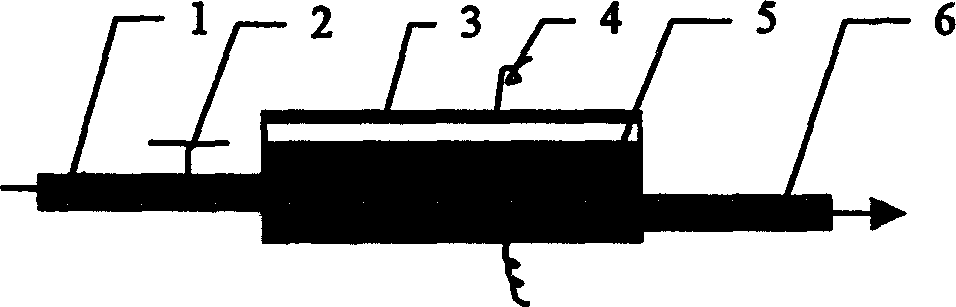

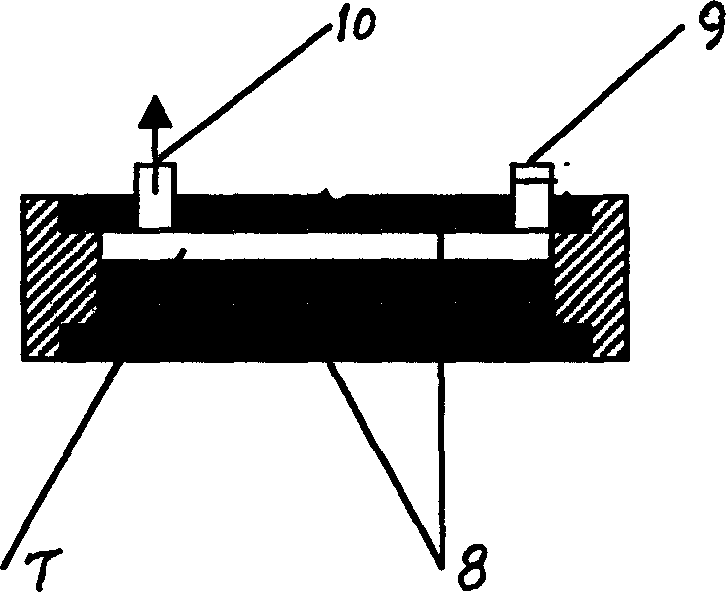

[0044] Such as figure 2As shown, the processor of the pulse electric field sterilization equipment of the present invention is composed of a material processing chamber 7, two electrodes 8 installed in the material processing chamber, a feed port 9 and a discharge port 10. The material processing chamber is a vacuum chamber. The outer layer of the material processing chamber is an insulating layer.

[0045] The material processing chamber 7 is in the shape of a cylinder, and the electrodes 8 are circular electrode plates, which are installed above and below the material processing chamber 7 respectively.

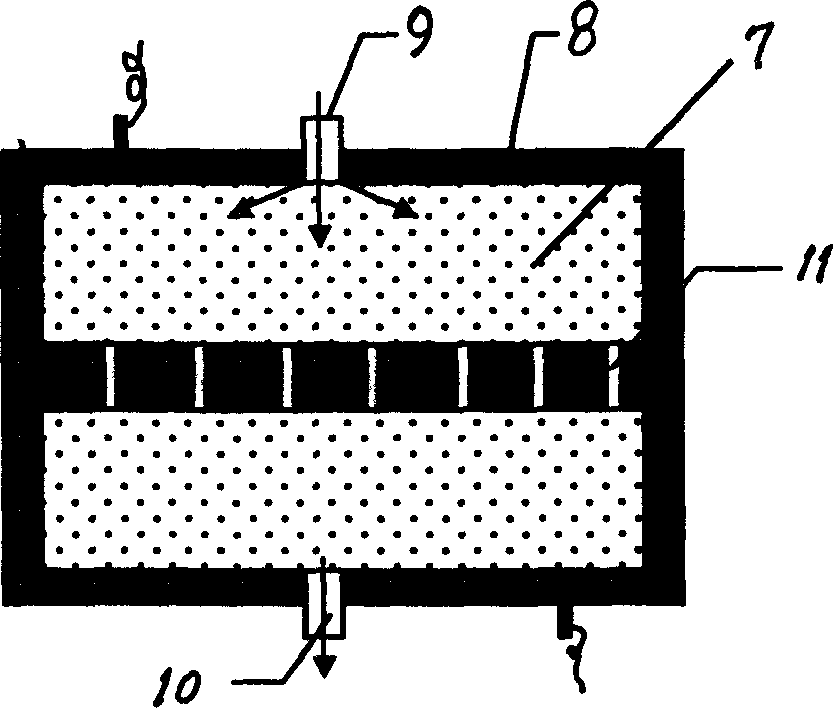

[0046] Such as image 3 As shown, a plurality of narrow holes 11 are arranged in the material processing chamber 7 .

[0047] The key to this design is to scientifically and rationally design the narrow holes for processing materials to obtain local enhancement of electric field intensity. The two sides of the narrow hole are insulating materials, and the two ends are li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com