Vapor-deposited coating device for vacuum vapor-deposited coating apparatus

An evaporation and vacuum technology, used in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of danger, time-consuming, and large inertness in the adjustment of evaporation rate, and is conducive to control, high power consumption, etc. The effect of loss, small cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

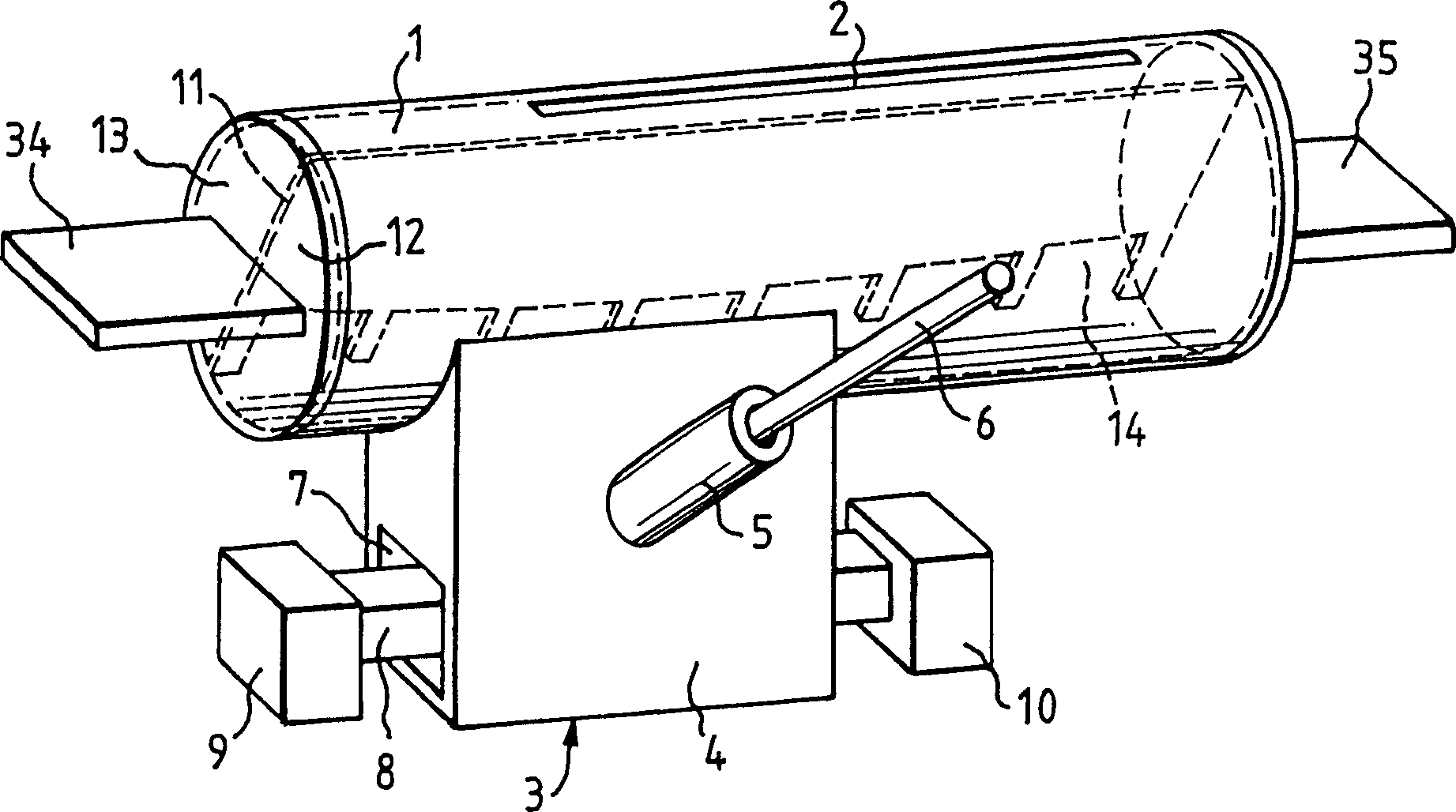

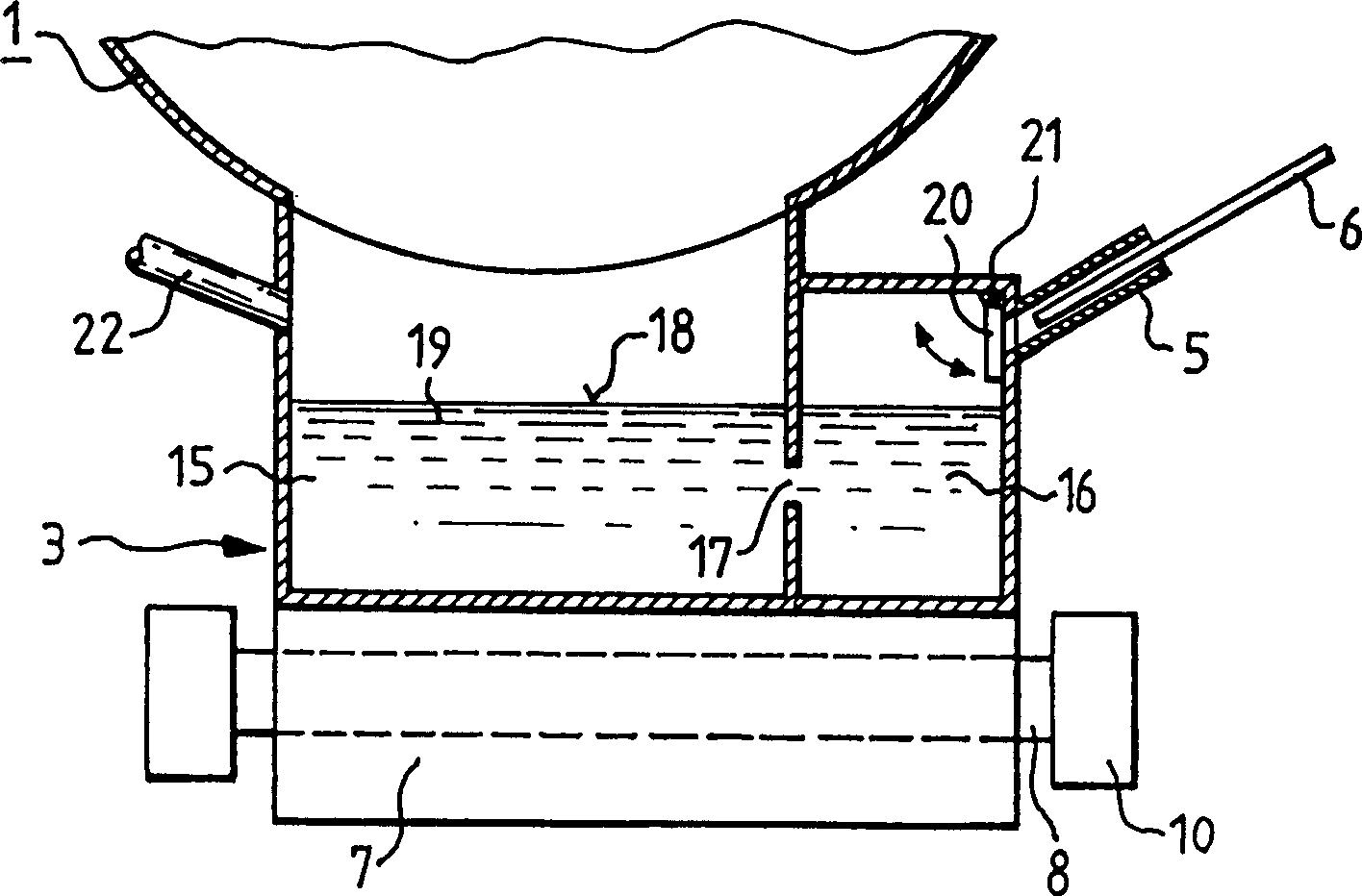

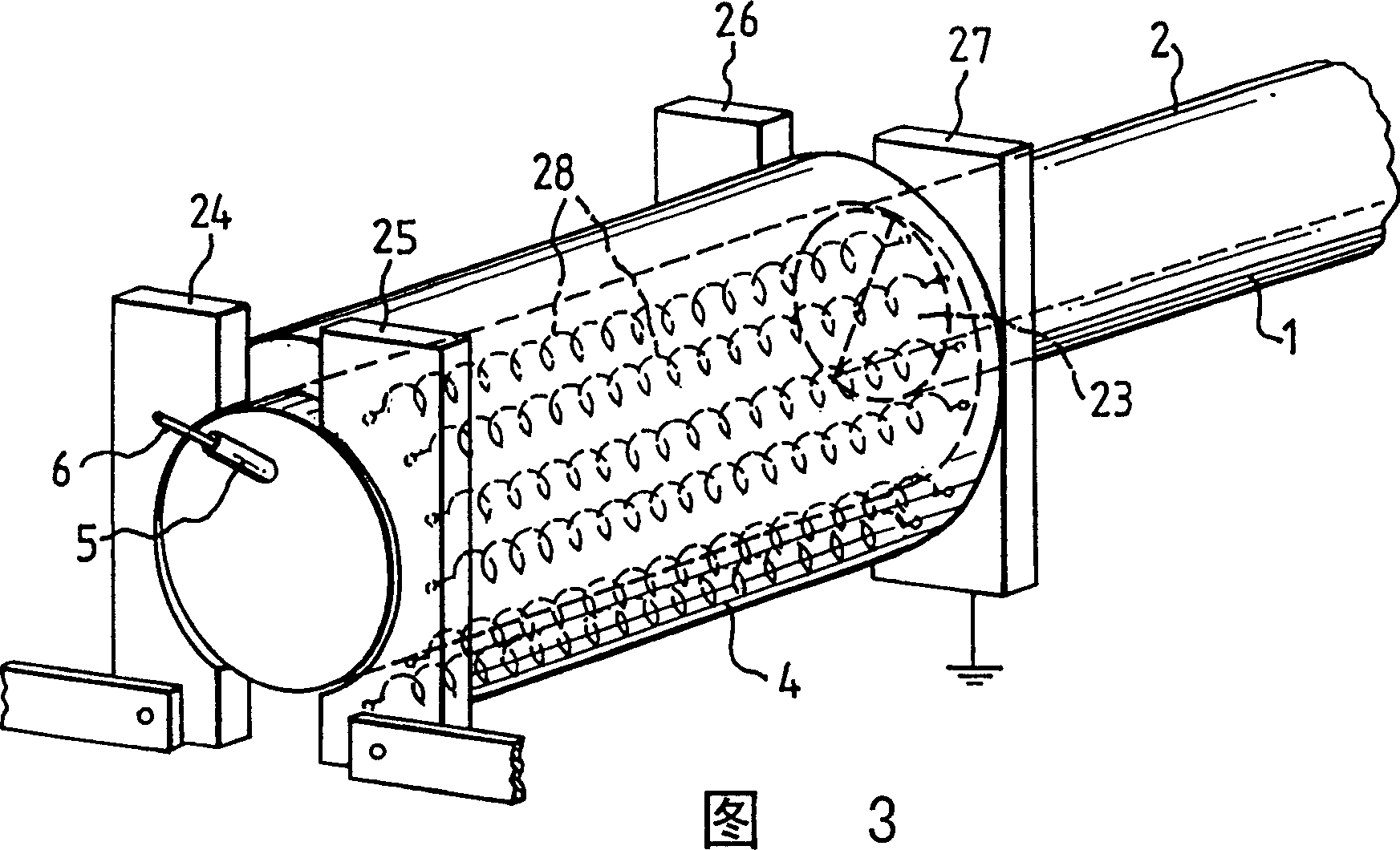

[0030] figure 1 The vapor deposition device shown as a whole in FIG. 2 is used in particular for the vapor deposition of zinc in coating systems and has a tubular nozzle body 1 . The nozzle body 1 has, on its outer surface, longitudinally extending nozzle slots 2 through which the steam for coating the film flows out during operation of the device. An evaporator 3 with a housing 4 is fastened to the underside of the nozzle body 1 . The evaporator housing 4 has an obliquely arranged feed pipe 5 through which the metal to be melted is fed into the evaporator 3 in the form of a wire 6 . For heating, the bottom of the evaporator housing 4 is designed as a steel pipe 7 with a rectangular cross-section, into which a heating rod 8 made of conductive ceramic penetrates. To heat the evaporator 3 , electrical energy flows through the heating rod 8 from one terminal 9 to the other terminal 10 of the heating rod 8 . The heating rod 8 here refers to a traditional boat-shaped evaporator....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com