Preparation method of granular sodium nitrate

A manufacturing method and a technology of sodium nitrate, which are applied to the preparation and molding of alkali metal nitrate, and the liquid is divided into bead droplets and granulated, can solve the problems such as insufficiently smooth particle surface, complicated preparation process, and potential safety hazard, and achieve the problem of not easy to agglomerate, The effect of regular and uniform particles and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

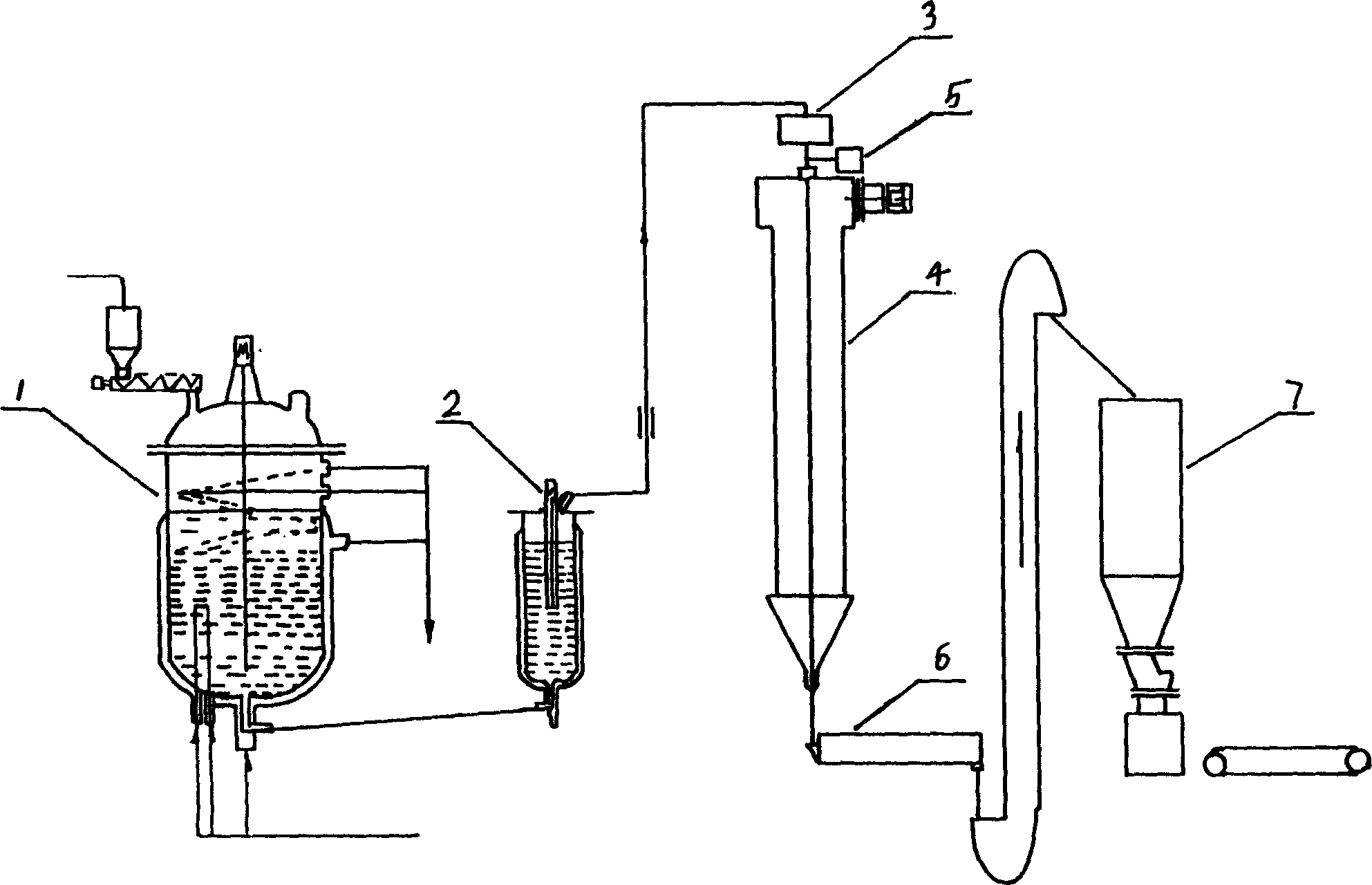

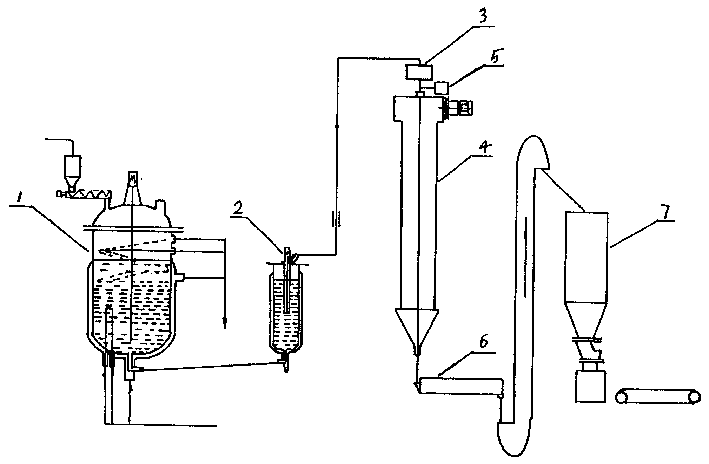

[0015] The present invention will be further stated below in conjunction with the drawings:

[0016] The manufacturing method of the industrial sodium nitrate product of the present invention is:

[0017] (1) Use powdered industrial sodium nitrate products in the prior art as raw materials, including sodium nitrate products produced by chemical methods and mined in mineral deposits; (2) Heat and melt the above raw materials into a liquid phase, the melting point of sodium nitrate is 308 ℃. This method of heating and melting can adopt the following methods, of course, other technical methods can also be adopted. As long as the heating can turn the solid phase sodium nitrate into liquid phase sodium nitrate, it is the method of the present invention. Heating and melting to make it into a liquid phase, one is to use the higher melting point of sodium nitrate to remove most or all of the water it carries during its melting process; the other is to facilitate the next step of spray gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com