Organosilicon water repellent compositions

A technology of polymers and copolymers, applied in other chemical processes, coatings, chemical instruments and methods, etc., which can solve problems such as lack of teaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1 - Solvent Based Composition

[0069] A mixture was prepared containing polymethylhydrogensiloxane, silicone resin and alkoxysilane n-octyltriethoxysilane in a ratio of 8:1:1. The mixture was diluted to 20% solids in KWIK-DRY(R) 66 aliphatic dry cleaning solvent and the composition was applied to lightweight concrete bricks. Use this 20% solids mixture in accordance with ASTM Test Method E-514 to achieve a coverage of 55 sq. ft. per gallon. The properties of the composition were determined according to the NCHRP 21-day drainage test by immersing the test cube in water for 30 seconds. The properties of the compositions under these conditions are listed in Table 1.

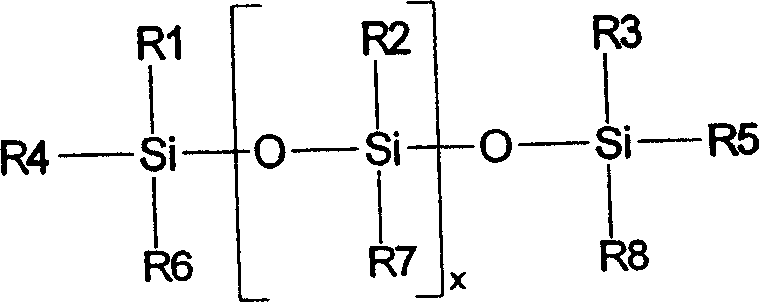

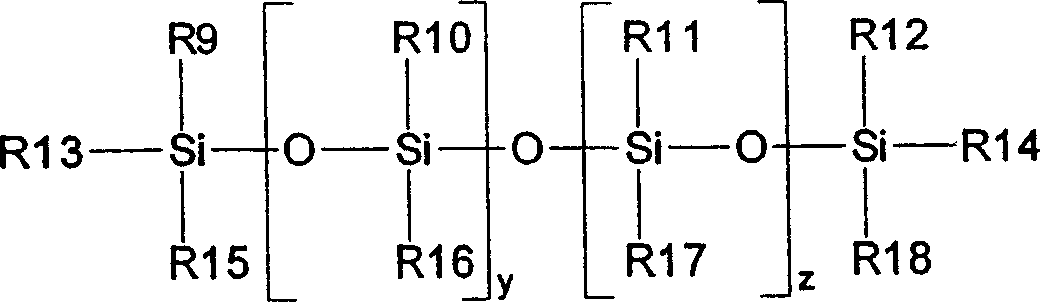

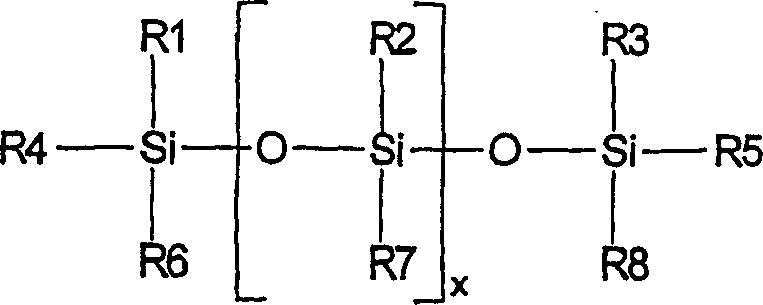

[0070] The polymethylhydrogensiloxanes used in this and subsequent examples have a silicon-bonded hydrogen content of 1.4-1.75% by weight and a viscosity of 20-40 centistokes (mm 2 / sec) of trimethylsiloxy-terminated polymethylhydrogensiloxane.

[0071] The silicone resin used in this example an...

Embodiment 2

[0072] Example 2 - Composition in Emulsion Form

[0073]Using the emulsification method described above, an emulsion was prepared with polymethylhydrogensiloxane, silicone resin, and the alkoxysilane n-octyltriethoxysilane. These three silicone components were mixed in a weight ratio of 8:1:1. Using 40 parts by weight of these three silicone components, 13.3 parts by weight of octamethylcyclotetrasiloxane as a volatile methylsiloxane, and 0.6 parts by weight of SPAN20 nonionic surfactant with an HLB value of 8.6 Agent, the ARALTONE T nonionic surfactant with the HLB value of 1.0 parts by weight of 9.0, the G-4280 nonionic surfactant with the HLB value of 1.4 parts by weight of 19.1, that is, PEG-80 sorbitan laurate, 0.8 parts by weight of the freeze-thaw additive ethylene glycol and 42.9 parts by weight of water to prepare the emulsion. The properties of the emulsion composition are shown in Table 1 when the emulsion was diluted to a 1:1 ratio with more water and applied t...

Embodiment 3-

[0074] Example 3 - Another composition in the form of an emulsion

[0075] Except for the addition of 2.2 parts by weight of cationic amino-functional polydimethylsiloxane containing reactive silanol functional groups stabilized by cationic and nonionic surfactants to the diluted emulsion of Example 2. Apart from the emulsion, a second emulsion was prepared according to the method used in Example 2. The properties of the emulsion composition are shown in Table 1.

[0076] Embodiment 4-comparative example

[0077] A solution containing 20% by weight n-octyltriethoxysilane was prepared in isopropanol using a titanate catalyst. The composition is applied to lightweight concrete blocks. This composition was used in accordance with ASTM Test Method E-514 to achieve a coverage of 55 square feet per gallon. The properties of the composition were determined according to the NCHRP 21-day drainage test method by immersing the test cube in water for 30 seconds. The properties ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com