Method for controlling clutch of single-tube washing machine

A clutch control and washing machine technology, which is applied to the control device of washing machines, other washing machines, washing machines with containers, etc. It can solve the problems of increased impact sound, inability to meet the silent requirements, and increase costs, and achieve the effect of increasing the number of pulses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

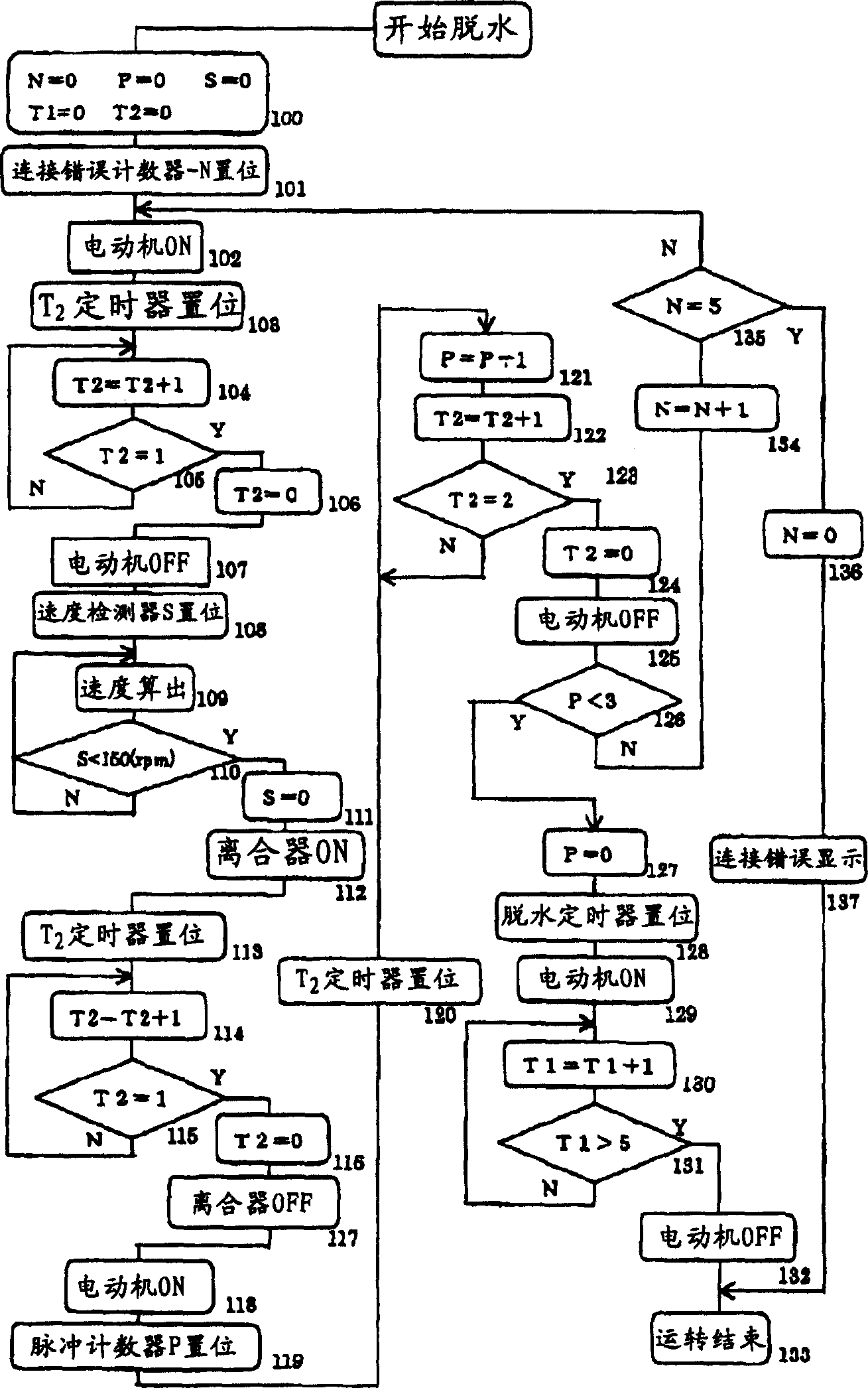

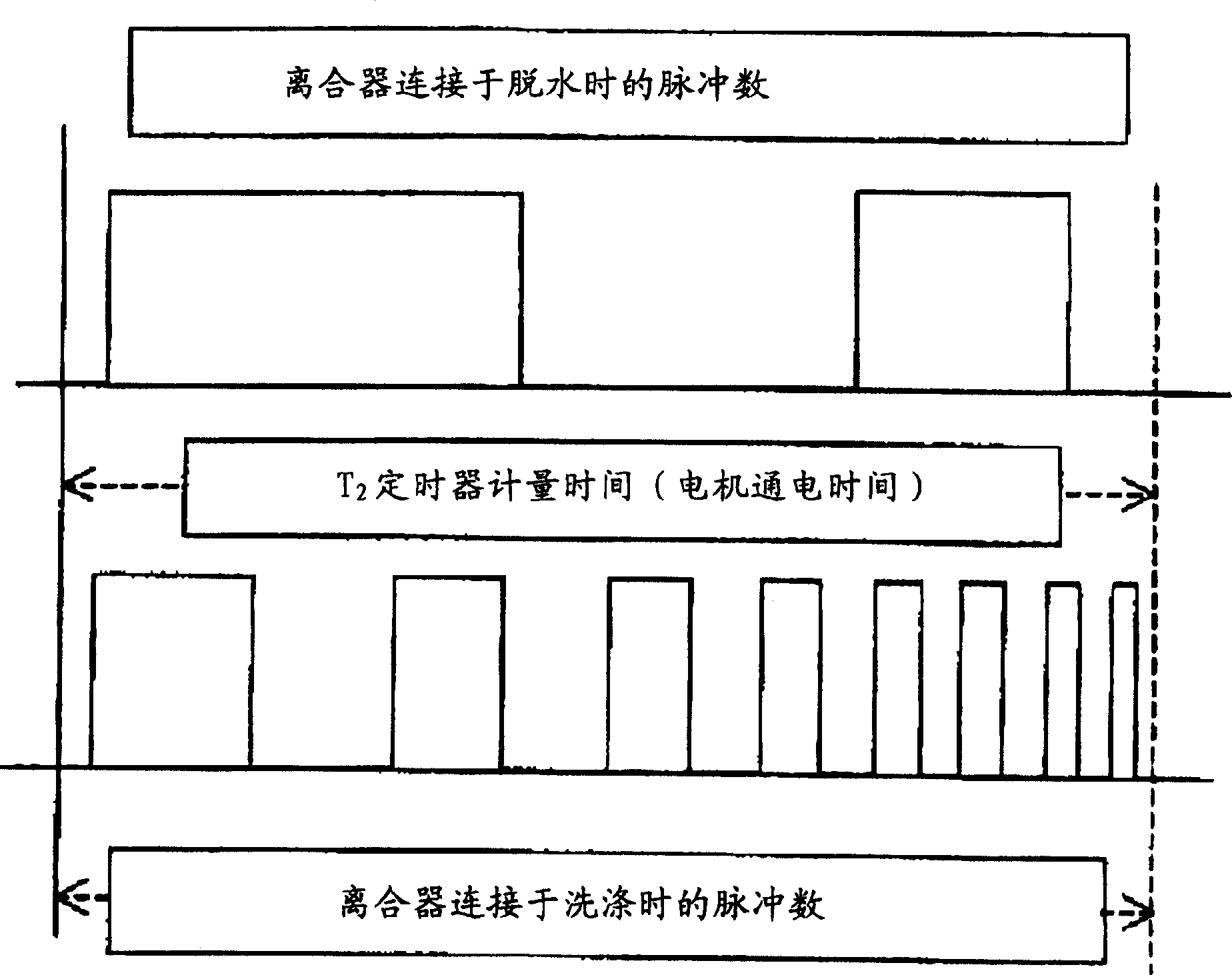

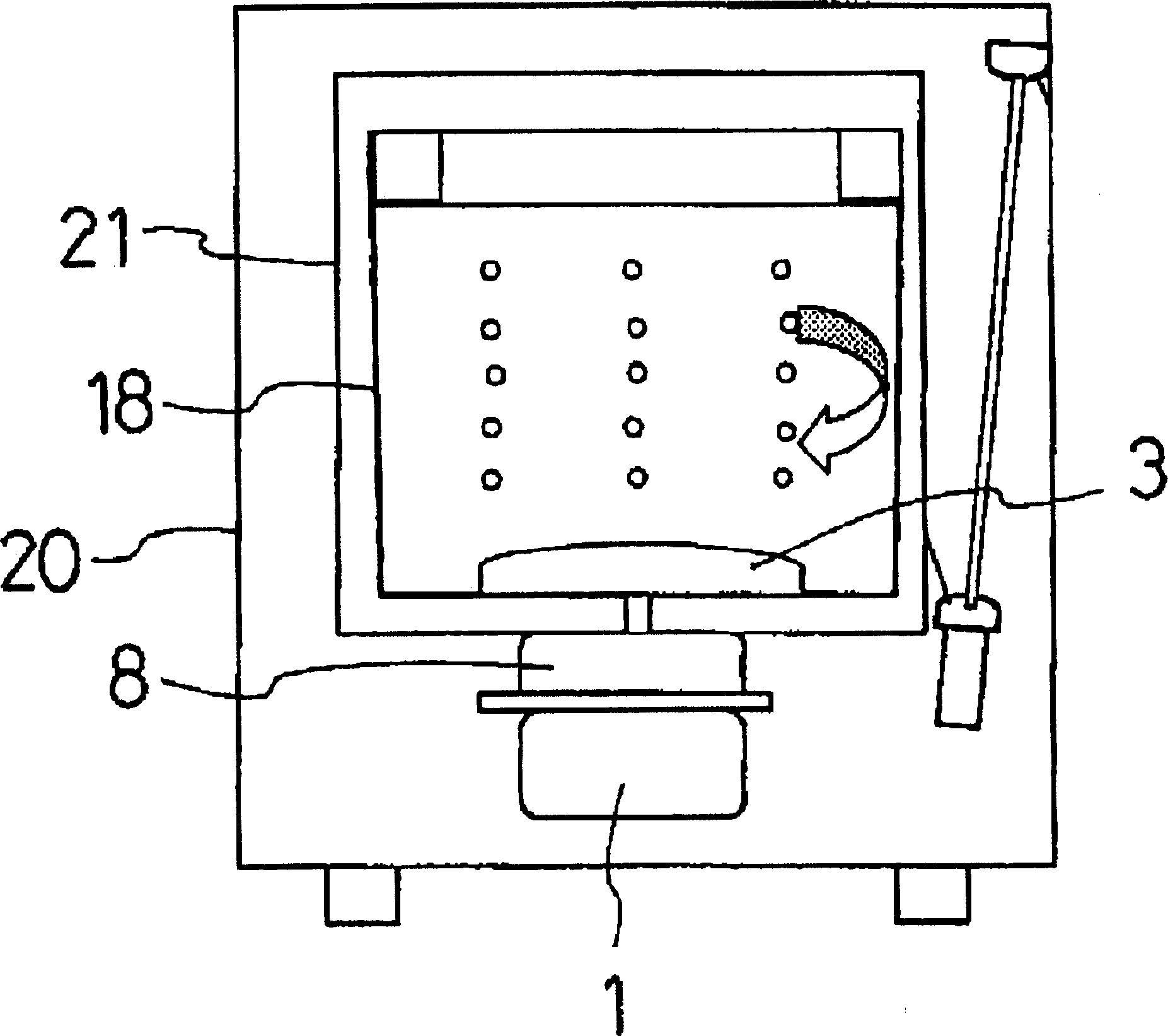

[0026] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 In order to show the sequence chart of the clutch connection control action of the clutch control method of the single-tub washing machine of the present invention, the structure of the single-tub washing machine implementing the clutch structure of the present invention is as follows: Figure 5 , since the overall basic structure of the clutch structure has been based on image 3 It has already been explained, and its detailed description is omitted here.

[0027] The clutch device 8 of the present invention is as Figure 4 , Figure 5 As shown, the lower part of the speed reduction mechanism 22 combined with the planetary gear is a pin clutch structure switched by an electromagnetic coil and a plunger, but the motor 1 uses, for example, an induction motor, and the front end of the washing shaft as the drive shaft 2 is fixed by a screw. The rotary vane 3 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com