Multifunctional chained block

A multi-functional, block-based technology, applied in the direction of building materials, etc., can solve problems such as easy peeling of painted surfaces, easy cracks in walls, and difficulties in concealed installation of pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

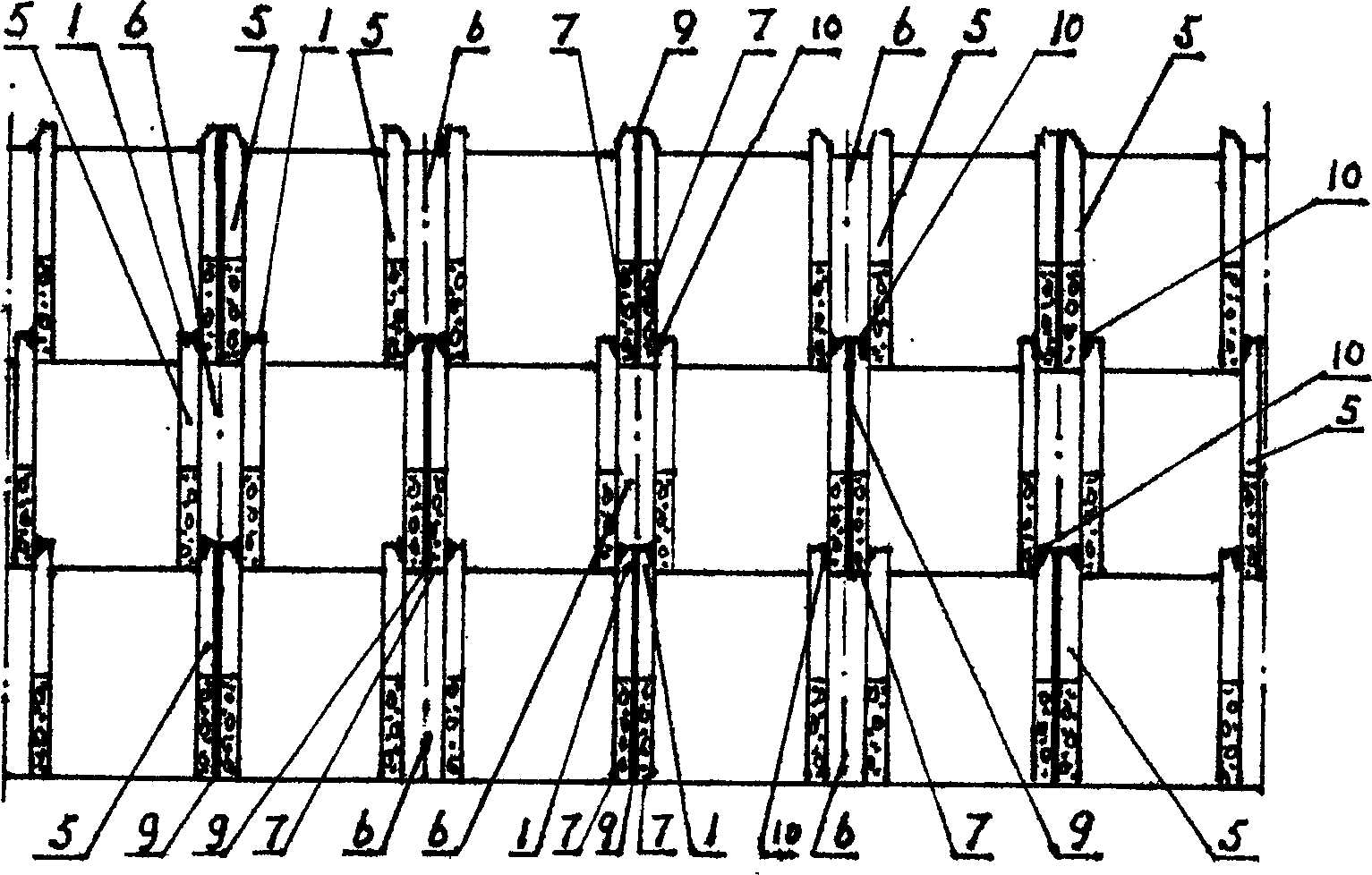

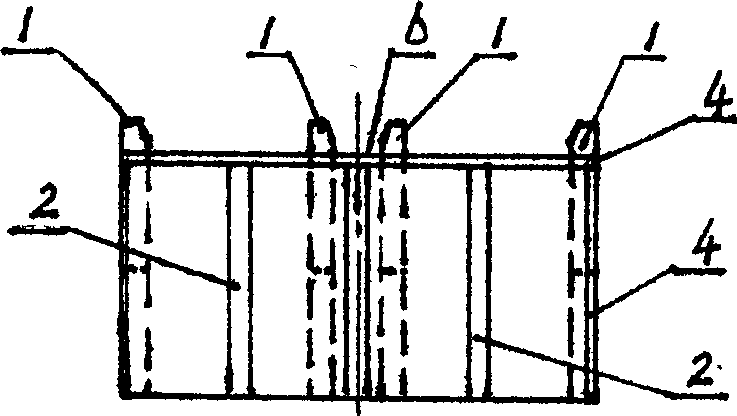

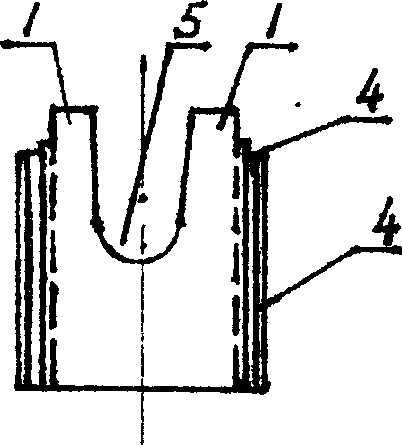

[0034] In conjunction with the accompanying drawings, it is described in detail as follows: figure 1As shown, the two end ribs 7 next to all the vertical mortar joints 9 on the masonry are locked up and down by the central holes 6 of the upper and lower skin blocks, because the contraction force of each block always shrinks towards its center. Displacement, due to the staggered masonry in the center, the law of contraction force between the upper and lower skins is naturally formed. This design uses this law to design the block into a structure with 3 holes and 4 ribs, so that a central hole 6 and 8 in the middle After the two protruding teeth 1 are built in the centering and staggered joints, all the vertical ash joints 9 are locked up and down within the scope of the center hole 6, so that the vertical ash joints use 8 protruding teeth 1 and the center hole 6 of the upper and lower skin blocks. The interlocking of the male and the female is limited. During the masonry operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com