Dipping solution and preparing method thereof

An impregnating solution and solution technology, applied in the field of impregnating solution and its preparation, can solve the problems of increasing energy consumption and equipment investment, increasing the cost of catalyst manufacturing, increasing operation steps, etc., achieving the simple and easy preparation method, saving time and simplifying operation The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

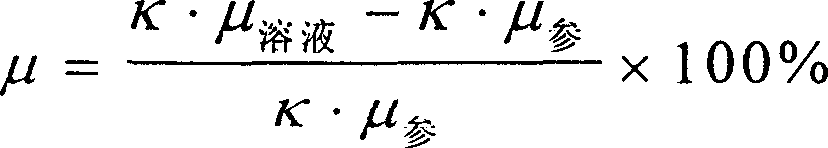

Image

Examples

Embodiment 1

[0015] Weigh 90g of water-soluble industrial grade ammonium heptamolybdate (the solubility of this ammonium molybdate in water is 50.0g / 100g water), add 150ml deionized water, stir to make the ammonium molybdate completely dissolve, then add 60.0g lemon acid, fully dissolved, then 180g of industrial-grade ammonium metatungstate and 140g of nickel nitrate were added to 150ml of deionized water, stirred and dissolved, then the two different solutions were mixed, and the volume of the solution was adjusted to 500ml with deionized water to obtain Solution A.

Embodiment 2

[0017] Compared with Example 1, the water-soluble industrial grade ammonium heptamolybdate add-on is changed into 180g, the ammonium metatungstate add-on is changed into 270.0g, and the add-on of citric acid is changed into 90.0g accordingly, all the other and embodiment 1 is the same, that is, the cost example, and solution B is obtained.

Embodiment 3

[0019] Compared with Example 1, the addition of ammonium metatungstate was changed to 90.0g, and the addition of citric acid was changed to 30.0g accordingly, and the rest were the same as in Example 1, that is, the cost example, to obtain solution C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com