Film coated glass bead for screen and its processing technology

A technology of coated glass and processing technology, which is applied in optics, instruments, projection devices, etc., can solve the problems of glass beads absorbing moisture, overlapping cloth, easy to absorb moisture, etc., to solve the problem of moisture absorption, prolong the service life, and improve the brightness The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

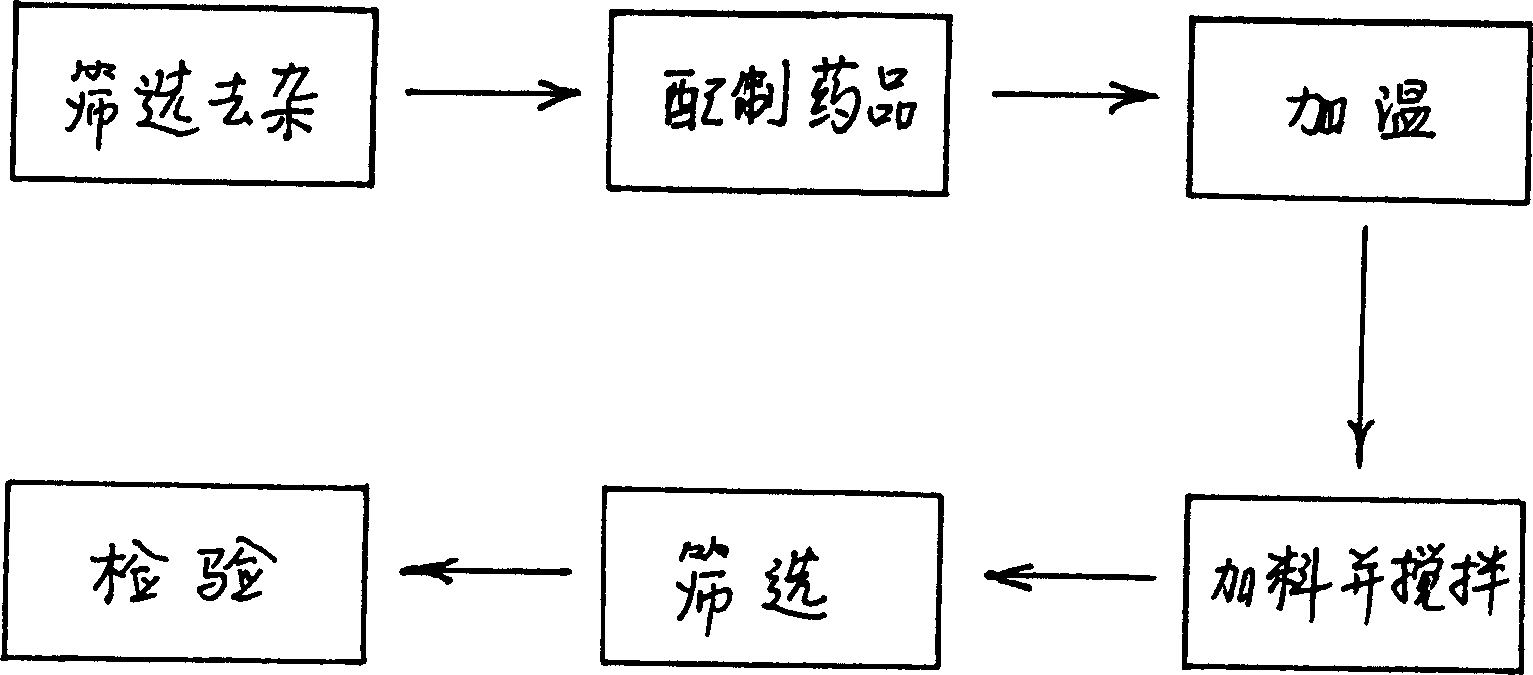

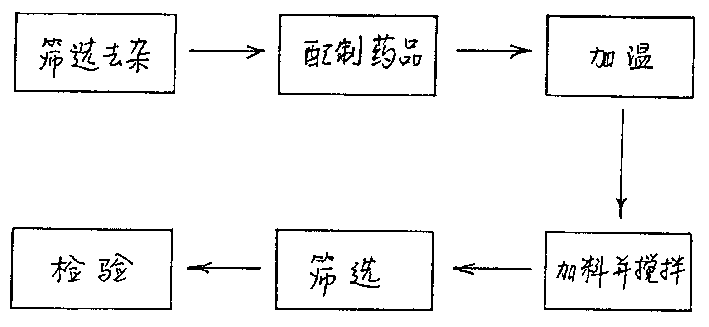

[0009] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0010] see figure 1 As shown, the following procedure was used to coat the glass beads:

[0011] (1) Screening to remove impurities: Use a sieve with a mesh number of 80 to select qualified glass beads, so that the particle size of the glass beads is between 0.05mm-0.25mm.

[0012] (2) Preparation of medicines: methyl silicone oil is used as the silane coupling agent. Put methyl silicone oil with a viscosity of 5000mpa s and sodium silicate with a mass concentration of 5% into the closed medicine barrels in the coating machine equipment respectively, and adjust the flow rates of the two liquids. The flow rate of methyl silicone oil is 1 drop / 10 Second, the flow rate of sodium silicate is 1 drop / 20 seconds, drop into the container in the coating machine, and mix the two liquids together.

[0013] (3) Warming: warm the feeder, and control the temperature at about 50℃...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com