Ceramic wall-floor brick

A technology of wall and floor tiles and ceramics, applied in the field of ceramic wall and floor tiles, can solve problems such as environment, vegetation damage, blocked rivers, flooding, etc., and achieve the effects of excellent internal quality, resource saving, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific implementation plan

[0023] Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

Billet

Feed

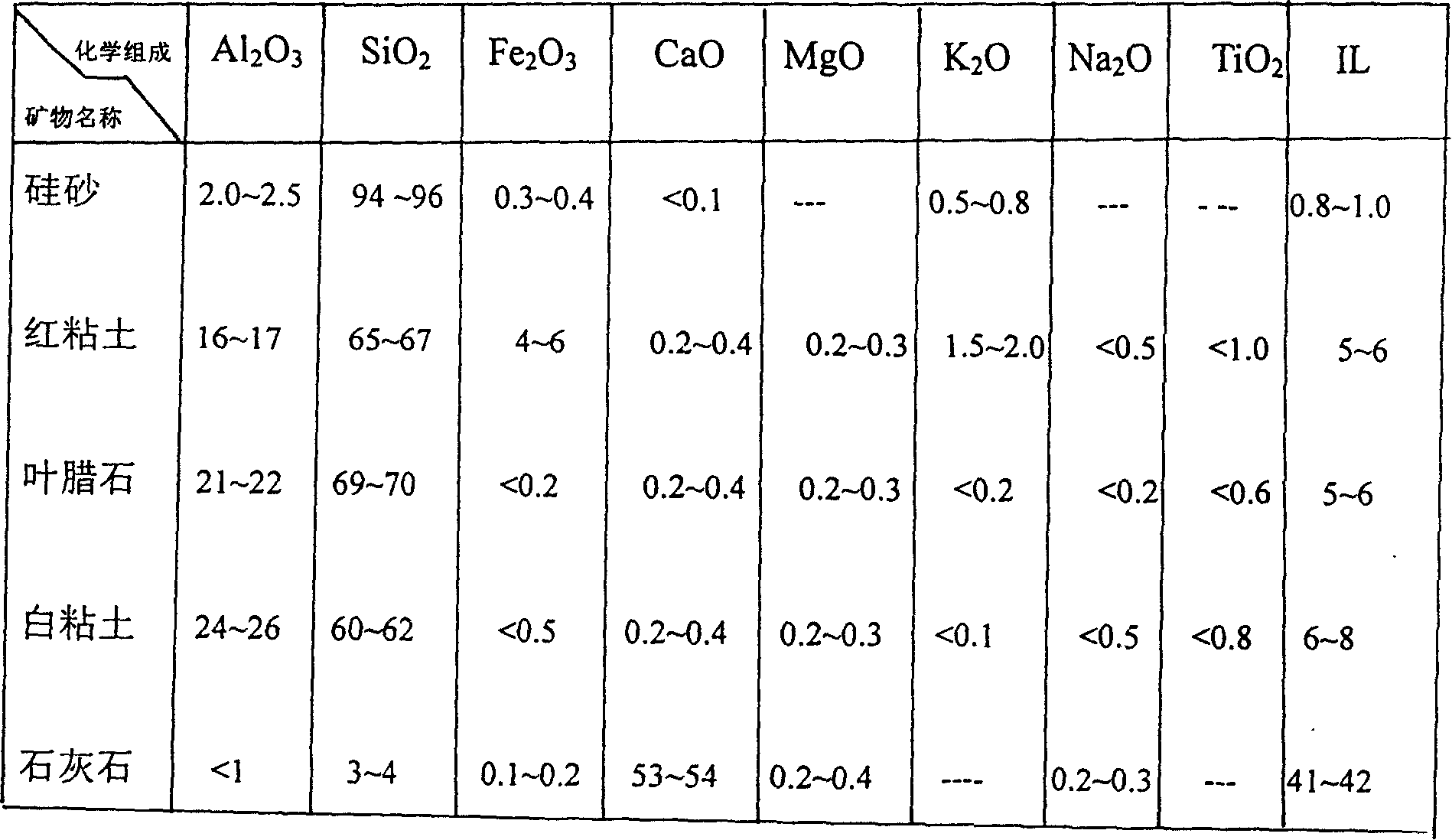

Silica Sand

Red clay

White clay

Limestone

22

35

19

8

16

21

34

18

9

18

20

35

15

10

20

20

33

17

10

20

22

34

18

8

18

21

35

19

9

16

Biscuit temperature

Glaze firing temperature

1160℃

1115℃

1160℃

1115℃

1160℃

1115℃

1170℃

1120℃

1170℃

1120℃

1170℃

1120℃

[0024] Product shrinkage

Product water absorption

Thermal shock resistance

0.7%

<16%

23Mpa

Qualified

0.6%

<16%

23Mpa

Qualified

0.5%

<16%

24Mpa

Qualified

0.6%

<15%

24Mpa

Qualified

0.8%

<15%

25Mpa

Qualified

0.7%

<15%

25Mpa

Qualified

[0025]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com