Process control system and method for automated continuous prodn. of chewing gum

A chewing gum, automatic technology, applied in the direction of confectionery, application, confectionery industry, etc., can solve the problems of lack of product consistency, inefficiency, lack of elastomers and other key components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0092] Wide range of changes or modifications to the preferred embodiments of this invention will be apparent to those skilled in the art. The above-mentioned preferred embodiments and the examples to be described below are only used to illustrate the present invention, not to limit the present invention. For example, different continuous mixing devices and different mixer configurations may be used without departing from the invention as long as the chewing gum base and chewing gum product are produced in a single continuous mixer using a mixing L / D of no greater than 40. Example 1: Testing the suitability of a continuous mixer

[0093] The preliminary tests described below can be used to determine whether a particular continuous mixer with a particular configuration meets the requirements for an efficient mixer for use in practicing the process of the invention.

[0094] 35.7% butyl rubber (copolymer of 98.5% isobutylene-1.5% isoprene, molecular weight 120,000-150,000, POLY...

example 2-6

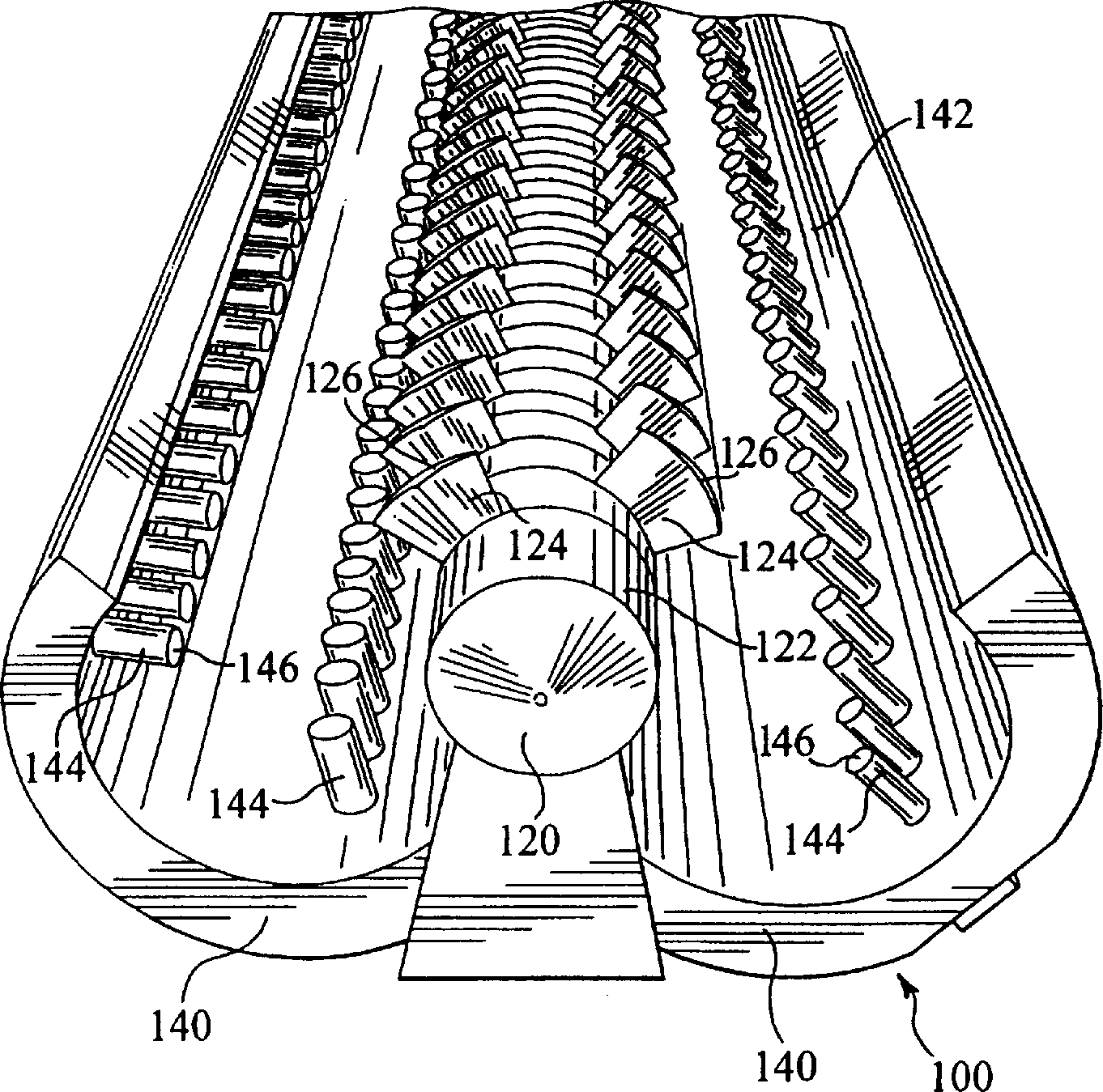

[0096] Also, the mixer must be of sufficient length to complete the manufacture of gum base and chewing gum products in a single mixer, with a total mixing L / D not exceeding 40. Any mixer meeting these requirements falls within the definition of a high efficiency mixer suitable for carrying out the method of the present invention. Example 2-6: Continuous production of chewing gum

[0097] The following example was carried out in the preferred manner above (unless indicated to the contrary) using a Buss kneader with a mixing screw diameter of 100 mm, having five mixing zones, a total mixing L / D of 19, and an initial conveying L / D of 1-1 / 3. No dies were used at the end of the mixer unless indicated to the contrary; the product mixture was discharged as a continuous rope. Each example was designed with a feed rate to obtain an output rate of 300 lbs / hr of chewing gum product.

[0098] The liquid components are fed by a volumetric pump into a large feed port and / or a smaller li...

example 2

[0104] This example illustrates the preparation of sugar chunk bubble gum. For this example, the shape of the mixer was slightly different from the preferred shape described above and was used in Examples 2-6. Specifically, a die with a circular hole of 30mm was installed at the outlet end of the mixer.

[0105] A blend of 68.9% high molecular weight polyvinyl acetate and 31.1% ground talc was added to the first large feed port 212 (see Figure 7 ). Polyisobutylene (preheated to 100°C) was also fed into port 212 at a rate of 3.95 lb / h. Downstream of the first mixing zone 220, acetylated monoglycerides are injected at a rate of 2.6 lb / h using a liquid injection (hollow barrel pin) port ( Figure 7 not shown) injection.

[0106] Additional polyisobutylene (100° C.) was added to the second large port 232 at a rate of 3.95 lb / h, glycerides of partially hydrogenated wood rosin at a rate of 13.4 lb / h. 43.6% glyceryl monostearate, A mixture of 55.9% triacetin and 0.5% BHT was ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com