High performance battery plate grid alloy

A battery plate and alloy technology, applied in the direction of electrode carrier/current collector, etc., can solve the problems of uneven cadmium composition, agglomerate frame segregation, and alloy corrosion resistance decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described below with embodiment again

[0020] Lead Pb

margin

margin

Cadmium Cd

1.60-1.80

1.60-1.80

Antimony Sb

1.50-1.70

1.50-1.70

Tin Sn

0.01-0.05

misch earth

0.01-0.05

Silver Ag

0-0.0005

0-0.0005

Copper Cu

0-0.0001

0-0.0001

Bismuth Bi

0-0.003

0-0.003

Arsenic As

0-0.0005

0-0.0005

Tin Sn

0-0.001

Zinc Zn

0-0.0005

0-0.0005

Iron Fe

0-0.0005

0-0.0005

Sum of Impurities

0-0.006

0-0.006

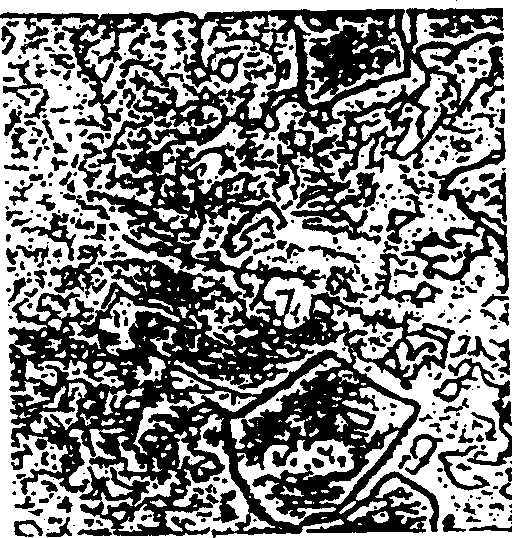

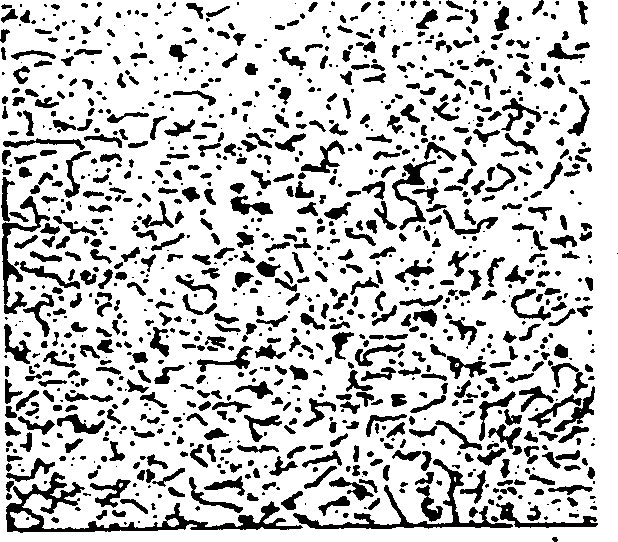

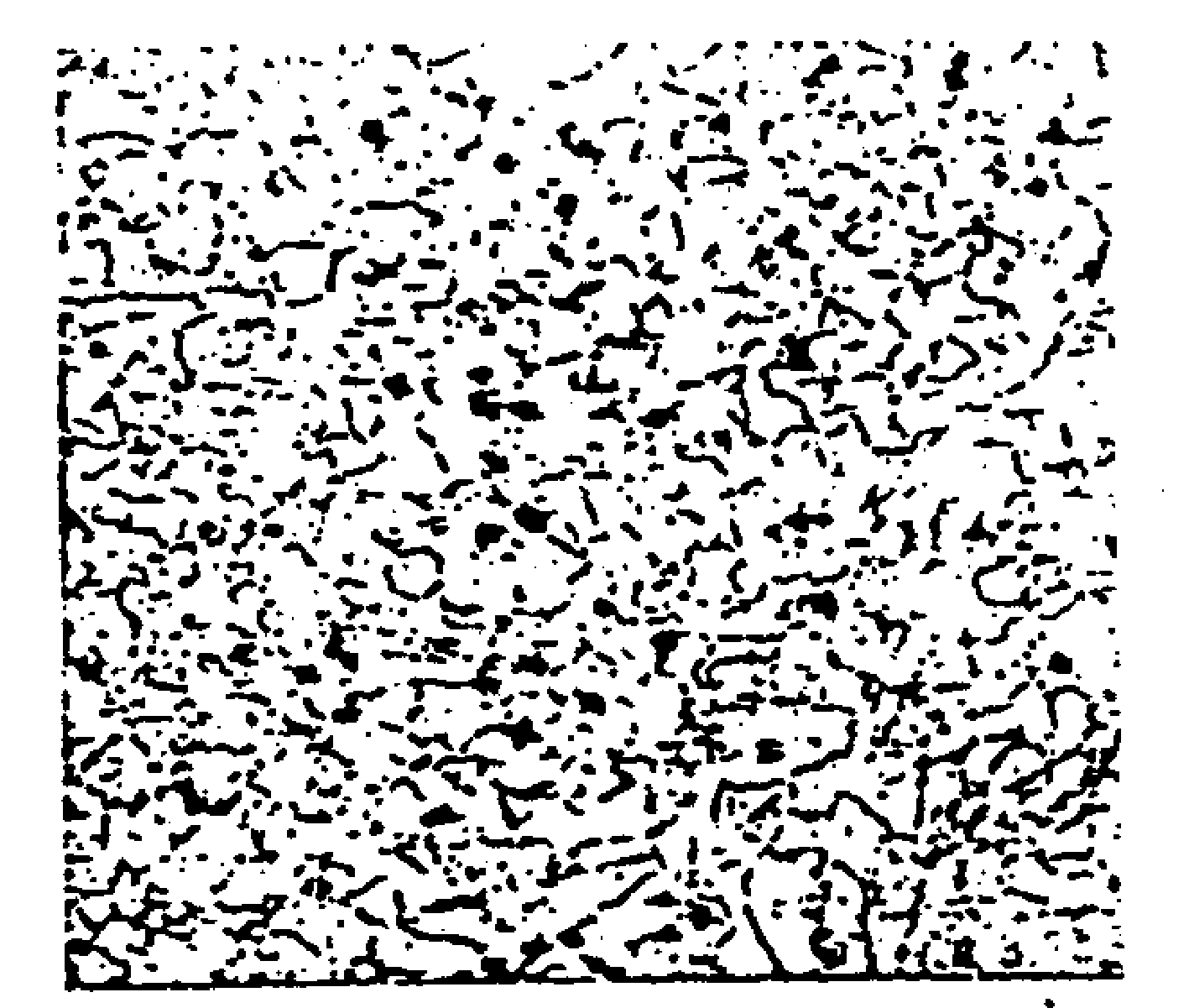

[0021] The addition of rare earth refines the grains of the alloy, solves the problem of agglomerated frame-shaped segregation, and then significantly improves the corrosion resistance, deep cycle performance and electrochemical performance of the alloy. figure 1 and figure 2 is the comparison of alloy phase diagrams befor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com