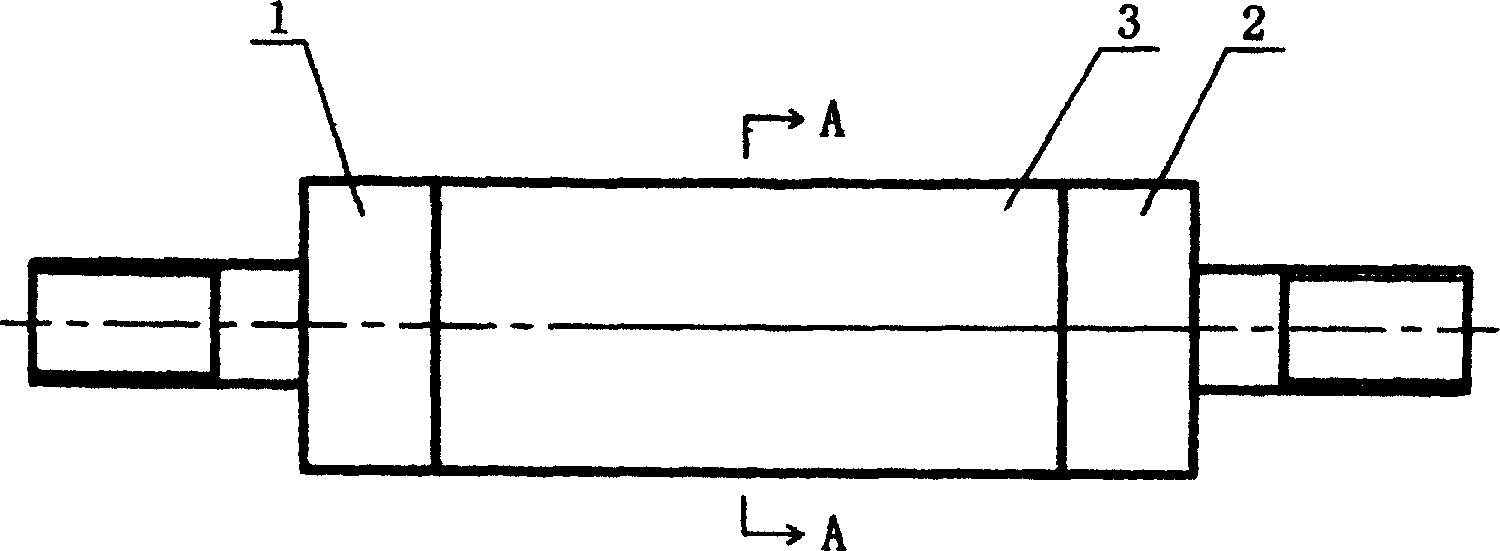

Far infrared environmental protection energy saving device and process for producing its infrared core element

A core component, far-infrared technology, applied in the field of preparation of far-infrared energy savers and their core components, can solve the problems of reduction effect, increased fluid flow resistance, inability to align through holes one by one, etc., and achieves improved quality and easy installation. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

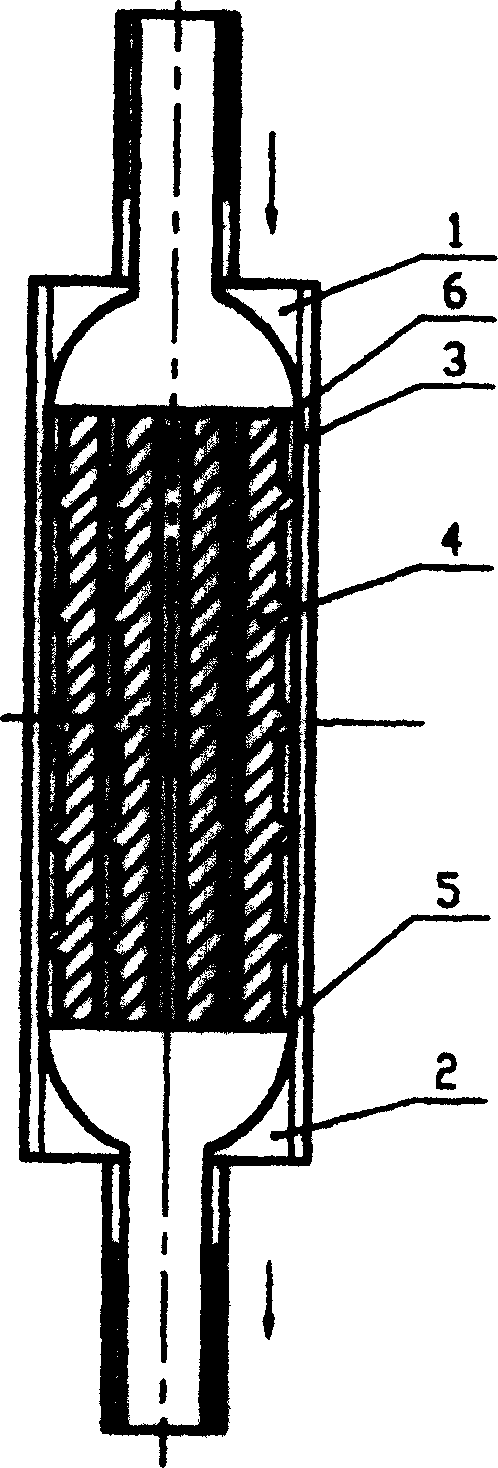

[0033] The method for preparing the infrared core element 4 comprises the following steps:

[0034] 1. Test the radiation wavelength of far-infrared materials with a far-infrared tester, select far-infrared materials with a radiation wavelength of 3.4 μm to 6.8 μm, and mix ingredients according to the following formula mass ratio:

[0035] PVC 33.5%

[0036] Plasticizer 14%

[0037] Stabilizer 2%

[0038] Lubricant 0.5%

[0039] Far infrared material 50%

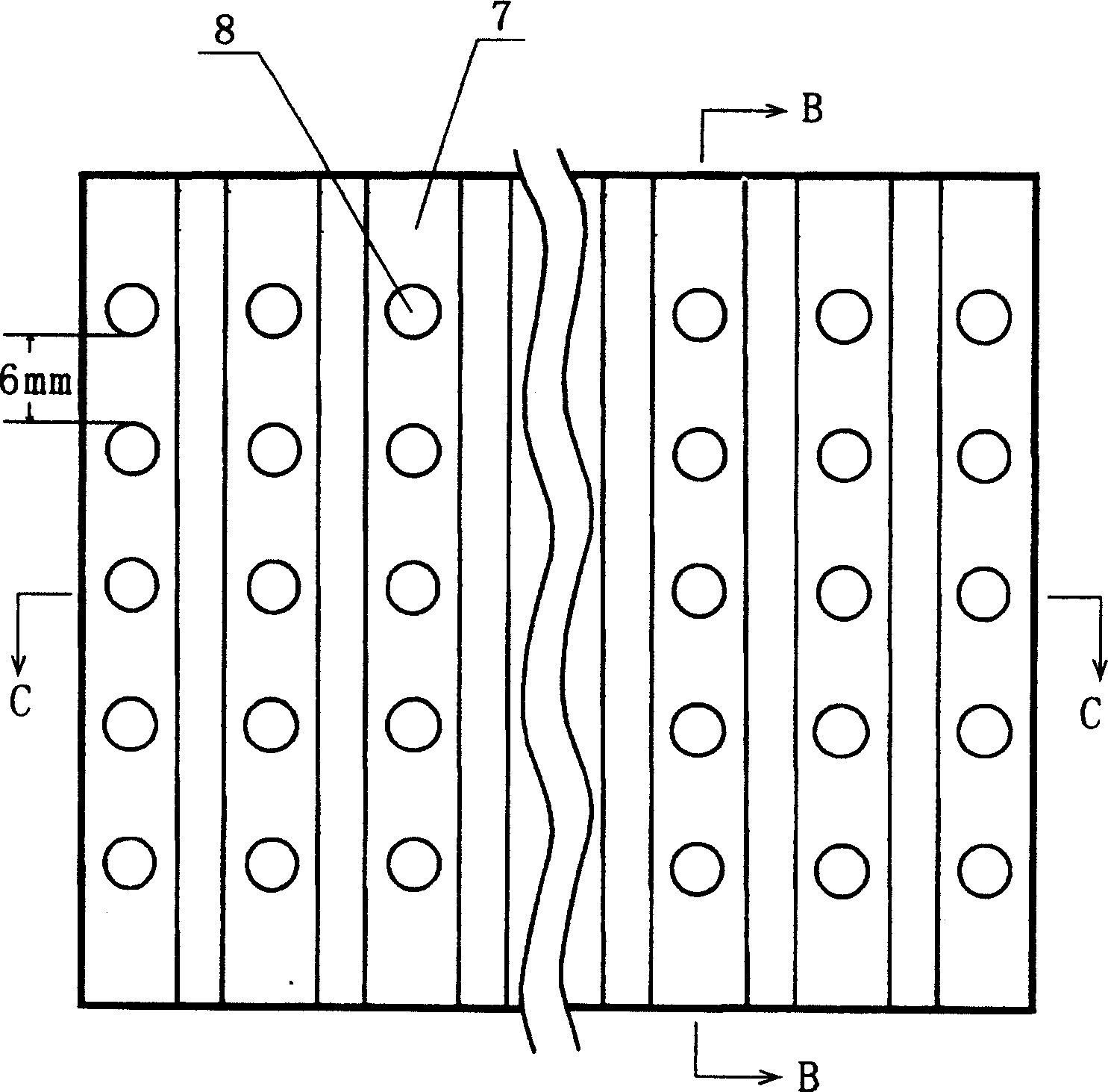

[0040] 2. Put the above ingredients in a pick-up roller kneader, knead and knead repeatedly at a temperature of 160°C until the ingredients are evenly mixed, and then send them to a calender for processing into a corrugated sheet with a thickness of 2.0mm such as image 3 As shown, and cut the thin plate according to the size of the pipe body.

Embodiment 2

[0042] The method for preparing the infrared core element 4 comprises the following steps:

[0043] 1. Test the radiation wavelength of far-infrared materials with a far-infrared tester, select far-infrared materials with a radiation wavelength of 3.4 μm to 6.8 μm, and mix ingredients according to the following formula mass ratio:

[0044] PVC 30%

[0045] Plasticizer 15%

[0046] Stabilizer 1.8%

[0047] Lubricant 0.2%

[0048] Far infrared material 53%

[0049] 2. Put the above ingredients in a pick-up roller kneader, knead and knead repeatedly at a temperature of 150°C until the ingredients are evenly mixed, then send them to a calender for processing into a corrugated sheet with a thickness of 1.6mm, and place the sheet according to the tube body The size is cut to size.

Embodiment 3

[0051] The method for preparing the infrared core element 4 comprises the following steps:

[0052] 1. Test the radiation wavelength of far-infrared materials with a far-infrared tester, select far-infrared materials with a radiation wavelength of 3.4 μm to 6.8 μm, and mix ingredients according to the following formula mass ratio:

[0053] PVC 37%

[0054] Plasticizer 12%

[0055] Stabilizer 3%

[0056] Lubricant 1%

[0057] Far infrared material 49%

[0058] 2. Put the above ingredients in a pick-up roller kneader, knead and knead repeatedly at a temperature of 170°C until the ingredients are evenly mixed, then send them to a calender for processing into a corrugated sheet with a thickness of 2.4mm, and press the sheet according to the tube body The size is cut to size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com