Film piezoelectric element and making method thereof and actuator device using same

A manufacturing method, piezoelectric body technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, material selection for piezoelectric devices or electrostrictive devices, piezoelectric devices/electrostrictive devices, etc., Ability to solve problems such as positional coincidence deviation, difficulty, mass production problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Embodiments of the present invention will be described below using the drawings.

[0060] first exemplary embodiment

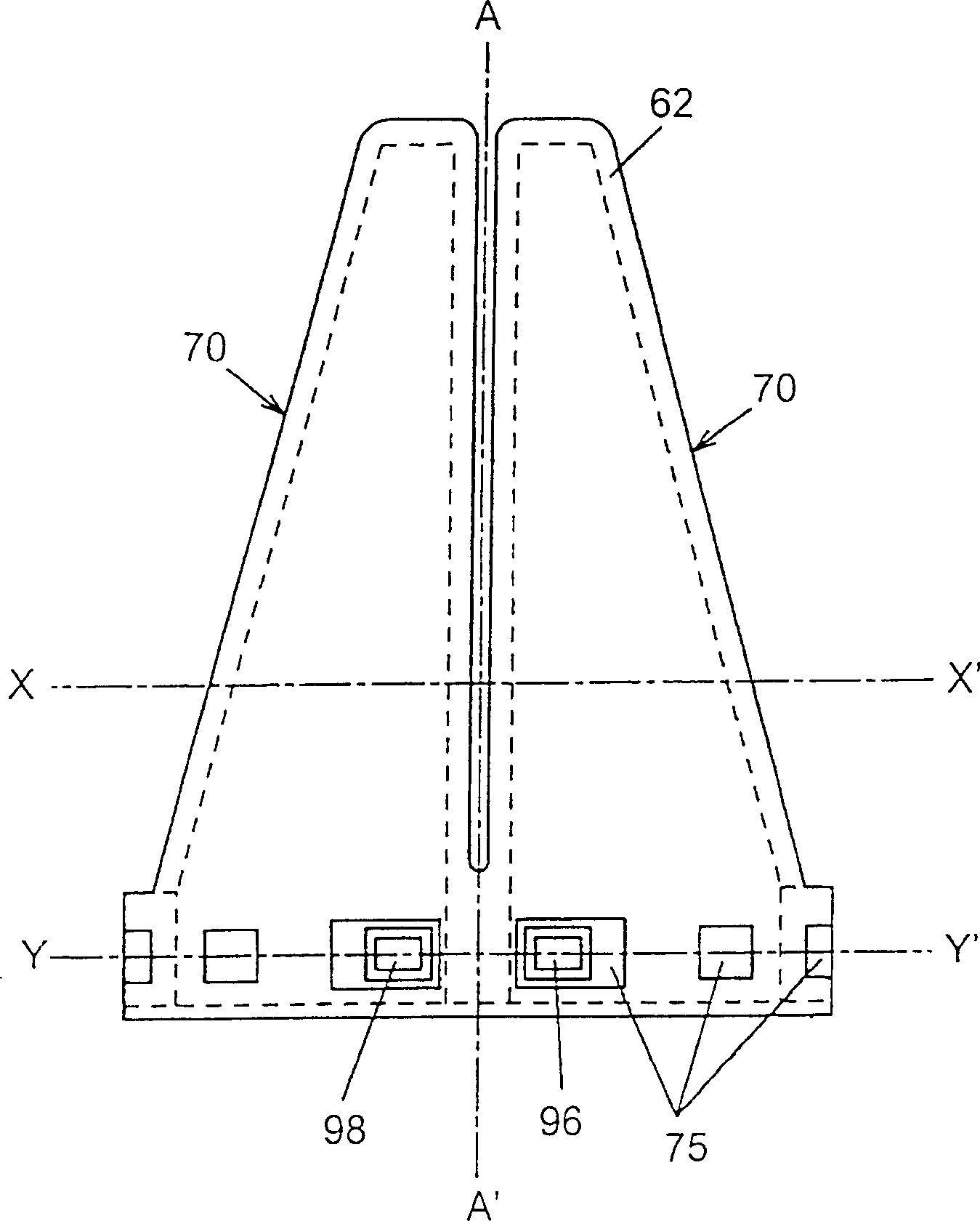

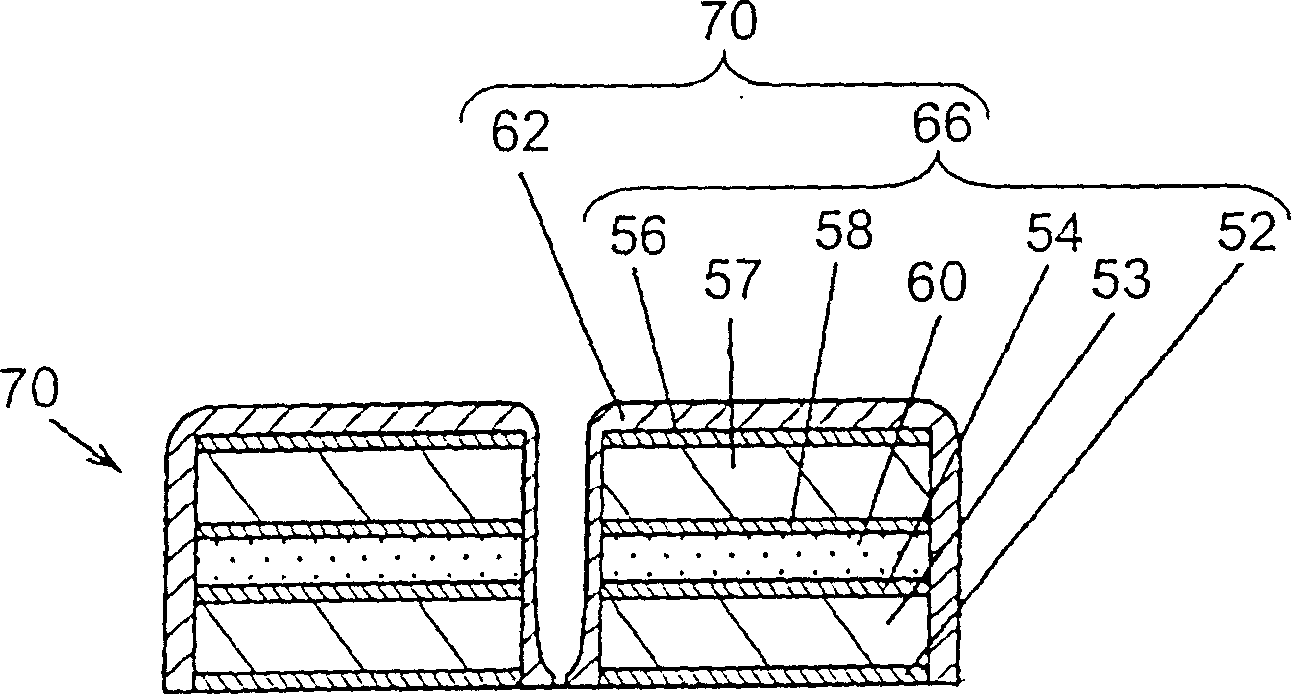

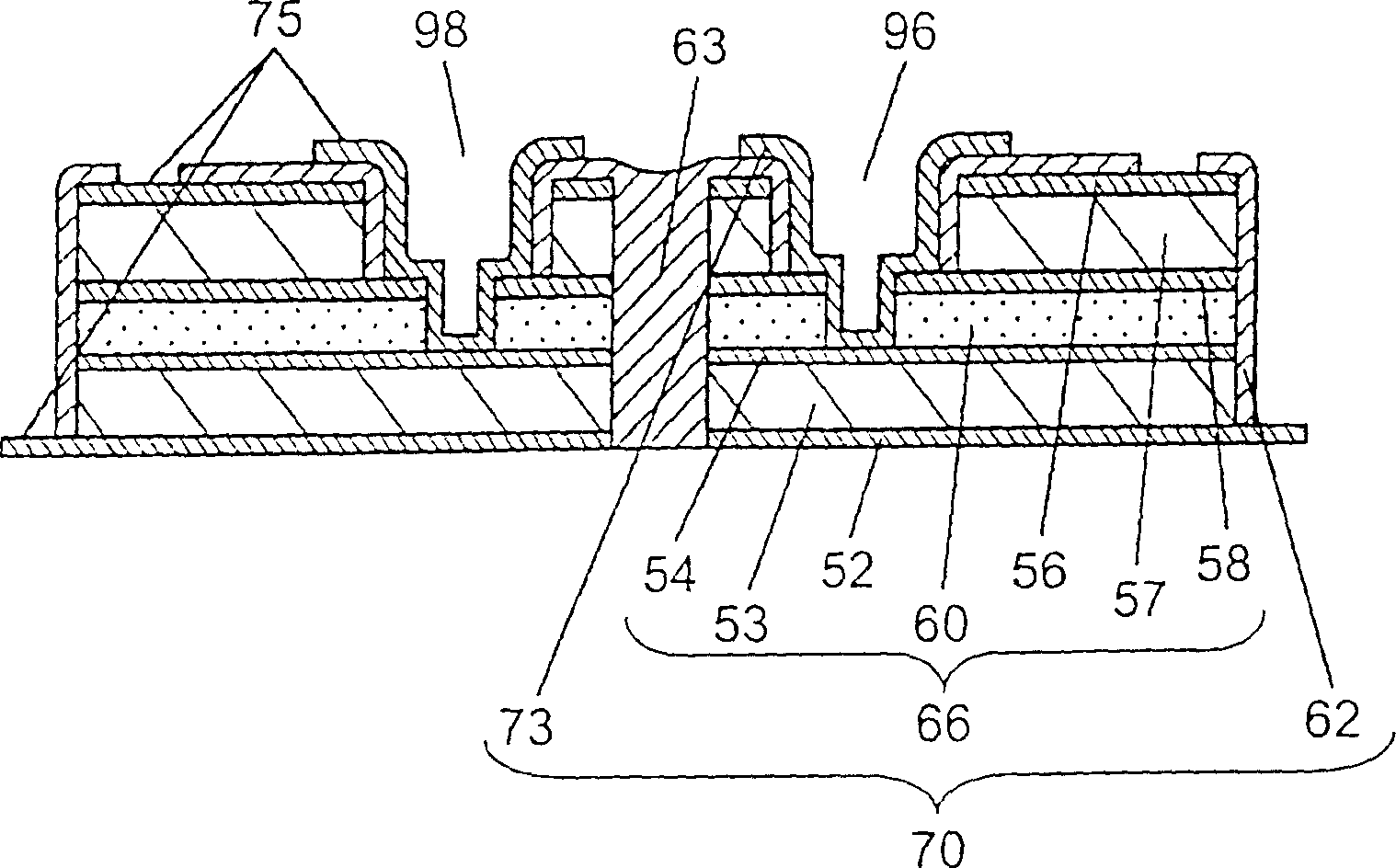

[0061] figure 1 This is a plan view of an actuator element made of a pair of two piezoelectric elements produced by the manufacturing method of the first embodiment. This actuator element is used to determine the minute position of a head slider at a predetermined track position on a disk with high precision in a disk recording and reproducing apparatus. The actuator element shown in the figure has a pair of two piezoelectric elements 70 formed in a mirror image relationship with respect to the line A-A'. along figure 1 The cross-sectional structures of the X-X' line and Y-Y' line are respectively shown in Figure 2A with 2B middle. These figures are used below to illustrate its structure.

[0062] Such as Figure 2A , as shown in 2B, a pair of piezoelectric body elements 70 have the same structure, and the first piezoelectric body thin film 53 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com