Method and apparatus for drying yarn package

A drying and yarn technology, which is applied in the field of yarn bundles composed of yarns, can solve the problems of warp yarn elasticity reduction, hindering shrinkage process, elongation loss, etc., and achieve the effect of preventing over-stretching and preventing local over-drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

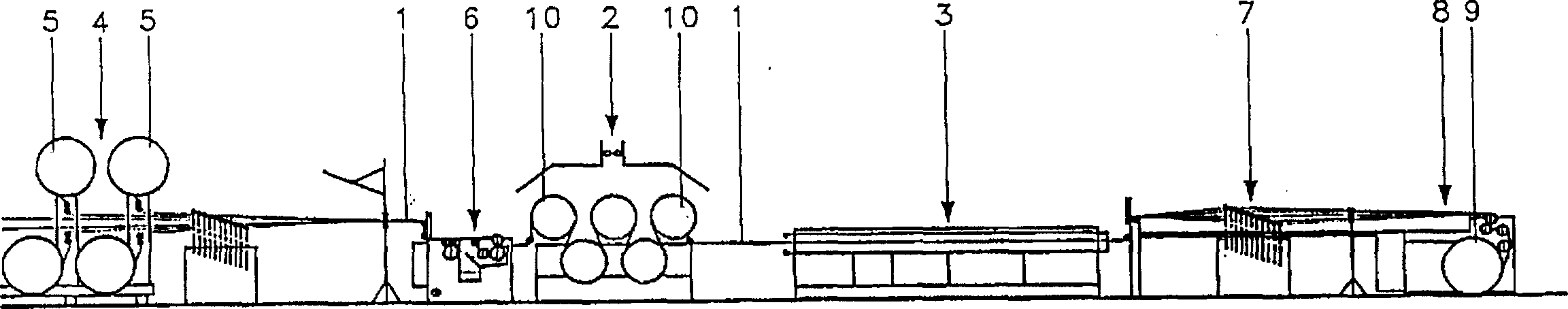

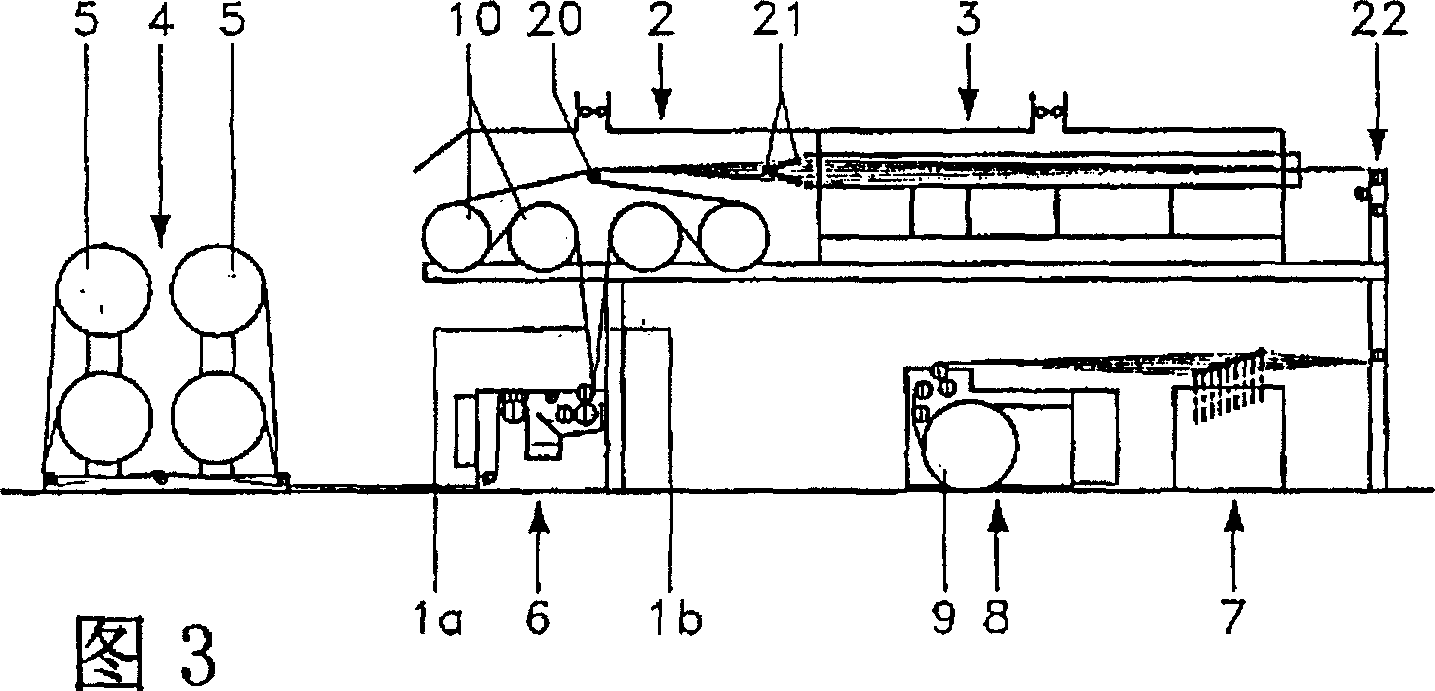

[0023] Such as figure 1 As shown, the device for drying a yarn bundle 1 consists of a contact dryer 2 with a plurality of drying cylinders 10 and a convection dryer 3 . The warp beam frame 4 and the sizing device 6 for accommodating the warp beam 5 are placed in front of the contact dryer 2, the warp beam can unwind the yarn bundle 1, and the yarn bundle 1 is transported into the sizing device. Arranged downstream of the convection dryer 3 is a twisting device 7 and a warping machine 8 , where the yarn bundle 1 can be wound onto a warp beam 9 .

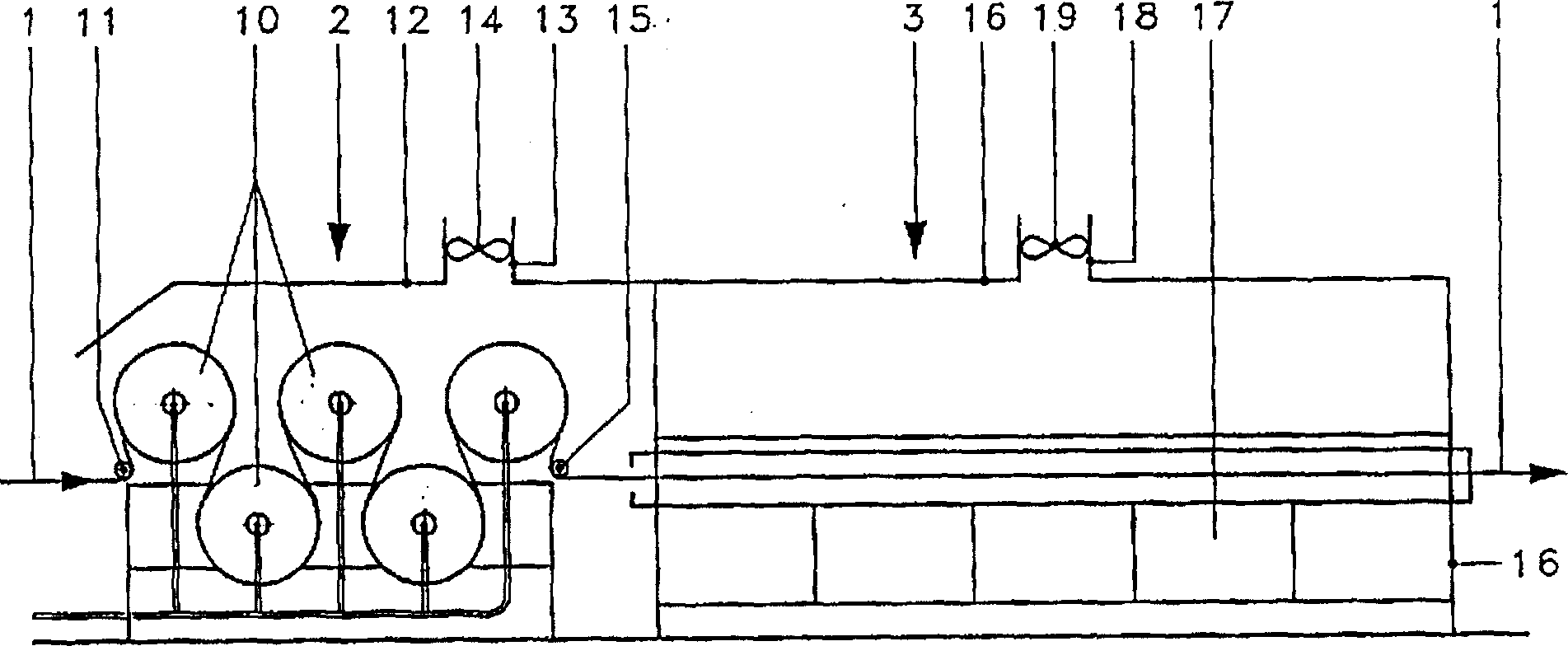

[0024] according to figure 2 , The contact dryer 2 is composed of five heatable drying cylinders 10, which are rotatably supported on the machine base. In this example the drying cylinders 10 are arranged on two levels such that they have a common horizontal tangent. The horizontal distance between two drying cylinders 10 is roughly equal to their radius. At the inlet of the contact dryer 2 a deflection guide roller 11 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com