Articles comprising a release liner having a high coefficient of friction and good roll stability

A technology of friction coefficient and items, applied in the field of manufacturing such items, can solve problems such as roll defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example A-D

[0122] Examples 1-4 and Comparative Examples A-D were made with Scotchlite High Brightness Grade Retroreflective Sheeting Series 3870 available from 3M Company in the U.S., without adhesive or release liner as the substrate, unless otherwise specified, in the following It is called "3870 tablets" in the examples. The adhesives or release liners in Table 1 were laminated to the 3870 sheets in the manner described in Table 2, either by release liner exchange or by direct coating.

[0123] When using the direct coating method, a solvent-free, tack-promoting acrylate adhesive is applied to a thickness of 0.08 mm (3 mils) on the release liner. The adhesive was cured with an EB unit commercially available from Energy Sciences, Wilmington, MA, under the trade designation "Electron Cure Series" (7961 system, models EC300 / 134 / 400) with a dose of 8 Mola at 200 KeV Germany. The adhesive coated release liner and 3870 film were bonded to the sheet by two nip rolls.

[0124] When using t...

Embodiment 5

[0128] Embodiment 5 and comparative example

[0129] The thermal expansion and contraction of the different release liners compared to the base sheet (3870 sheets with adhesive) were measured in an attempt to correlate this physical property with the observed roll stability.

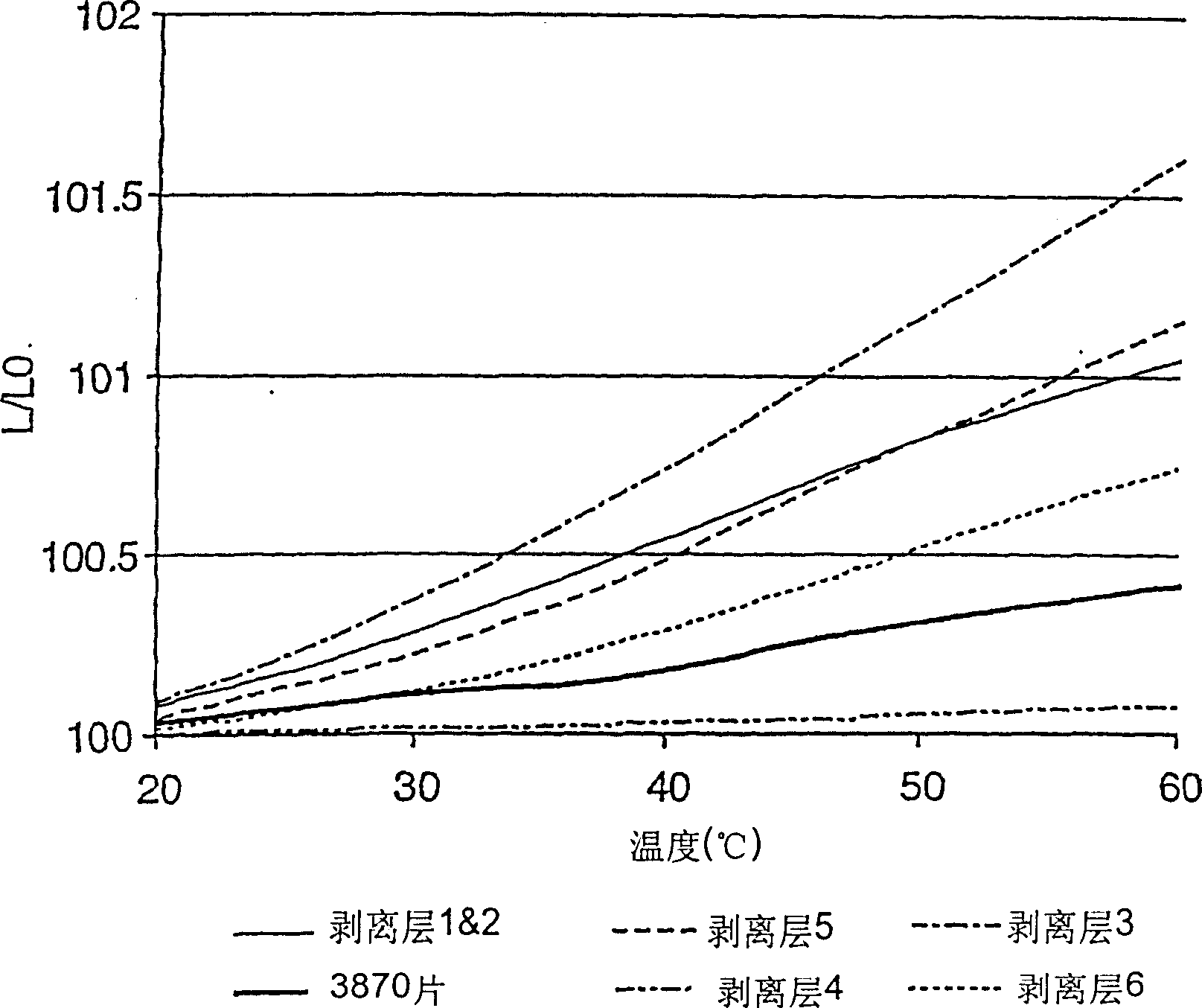

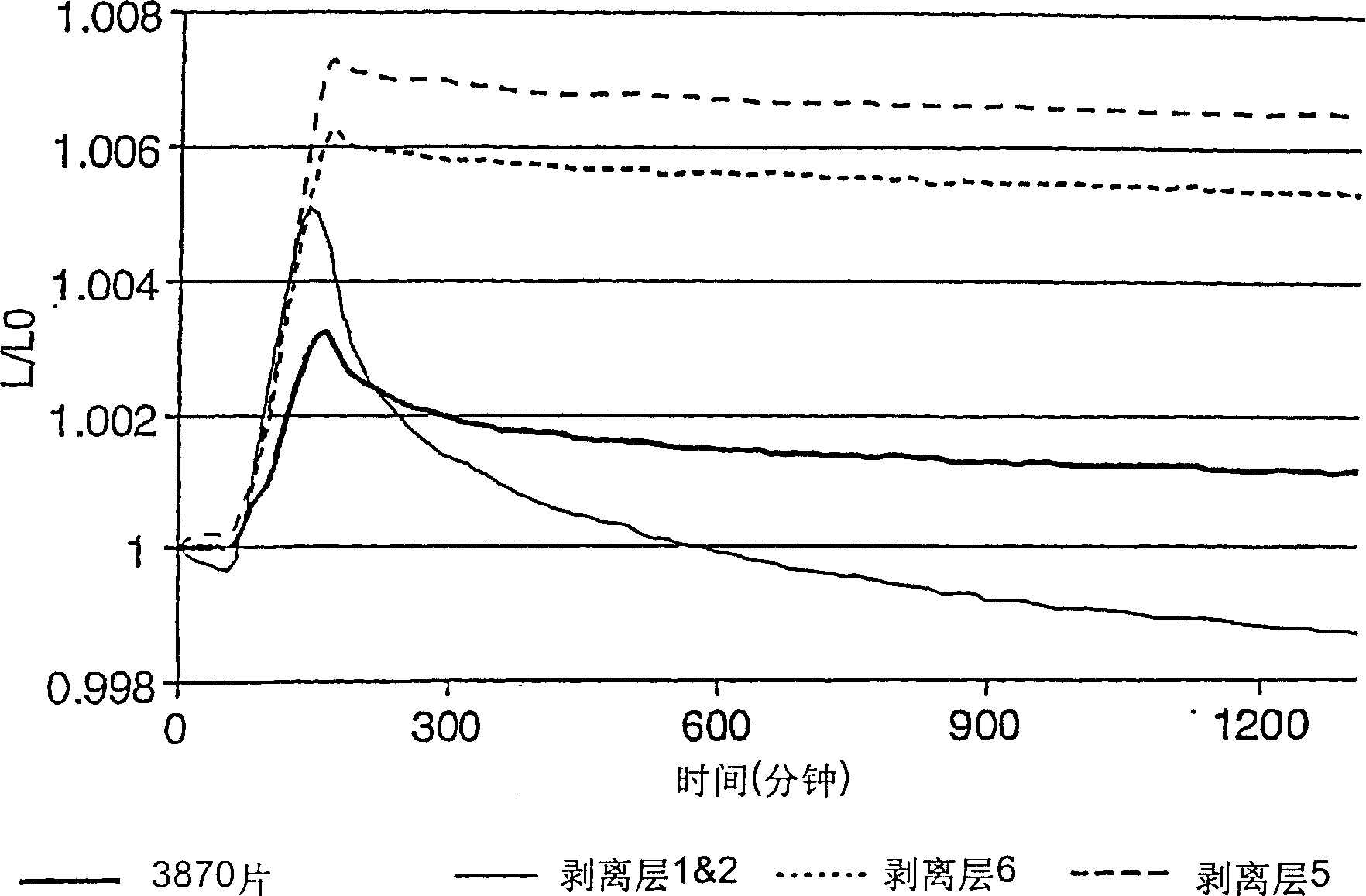

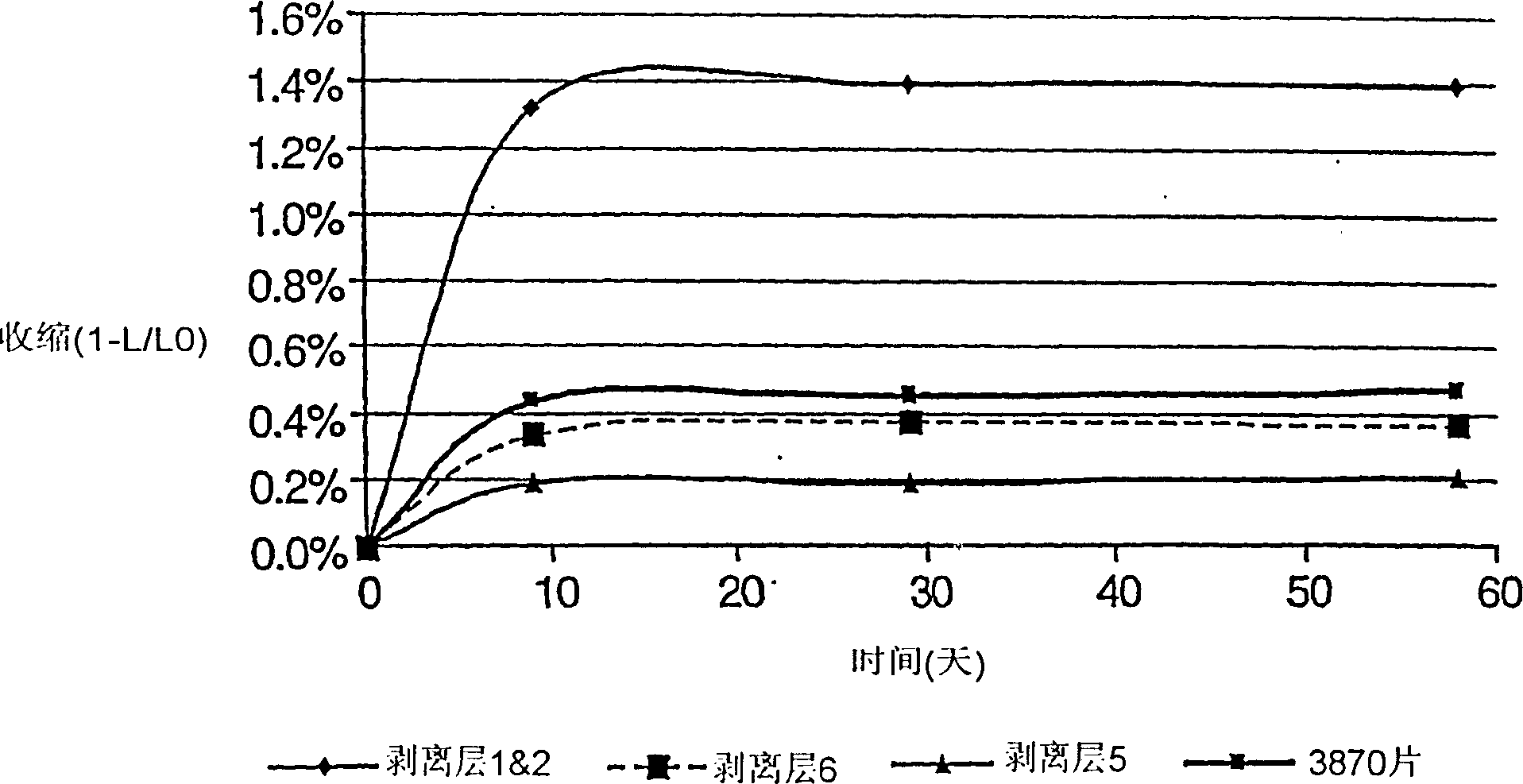

[0130] Example 5 (release liners 1 and 2) and comparative examples (release liners 3-6 and 3870 sheets with adhesive) were completed by individually cutting and testing samples using the thermal expansion test method described previously.

[0131] figure 1 is a plot of L / L0 (where L is the length in mm of the temperature change and L0 is the initial length of the sample in mm) times 100 versus temperature (°C). figure 1 Release Liner 6 shows the closest thermal expansion to 3870 sheets, however Release Liner 6 in Table II shows poor roll stability. Release liners 1 and 2 did not thermally expand much like the 3870 sheet compared to release liner 6, showing good roll stability. therefore, figure 1 The...

Embodiment 6 and comparative example E

[0137] Release liner 1 and release liner 2 were coated with solvent-free acrylate adhesive with a thickness of 0.1 mm (5 mils). The adhesive coated on release liner 1 was 93 / 7 isooctyl acrylate / acrylic acid (IOA / AA). The adhesive coated on release liner 2 was 95 / 5 IOA / AA with 12% by weight tackifier available from Hercules, Wilmington, DE under the trade designation "Foral 85". Both adhesives were hot melt coated onto the release liner using a twin screw extruder and a rotary extrusion die.

[0138] The adhesive surface of each adhesive-coated release liner was laminated to a 0.08 mm thick polyolefin film. The adhesive was cured and cross-linked by EB through the polyolefin film, and the CB300 / 45 / 380 EB device purchased from the Energy Sciences Company of Wilmington, Massachusetts was used. Volt down.

[0139] The peel value of each release liner adhesive layer at each EB radiation dose was determined according to Peel Test Method A described above and is shown in Table III...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com