Emptying oil cleaning tank diving oil pump

A technology for submersible pumps and warehouse sweeping, which is applied in the direction of pumps, pump devices, non-variable pumps, etc. It can solve the threat to the health and safety of operators, centrifugal pumps do not have gas-liquid mixed transmission, and the layout of loading and unloading pipelines is complicated, etc. problems, to achieve the effect of easy layout and control, compact structure and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

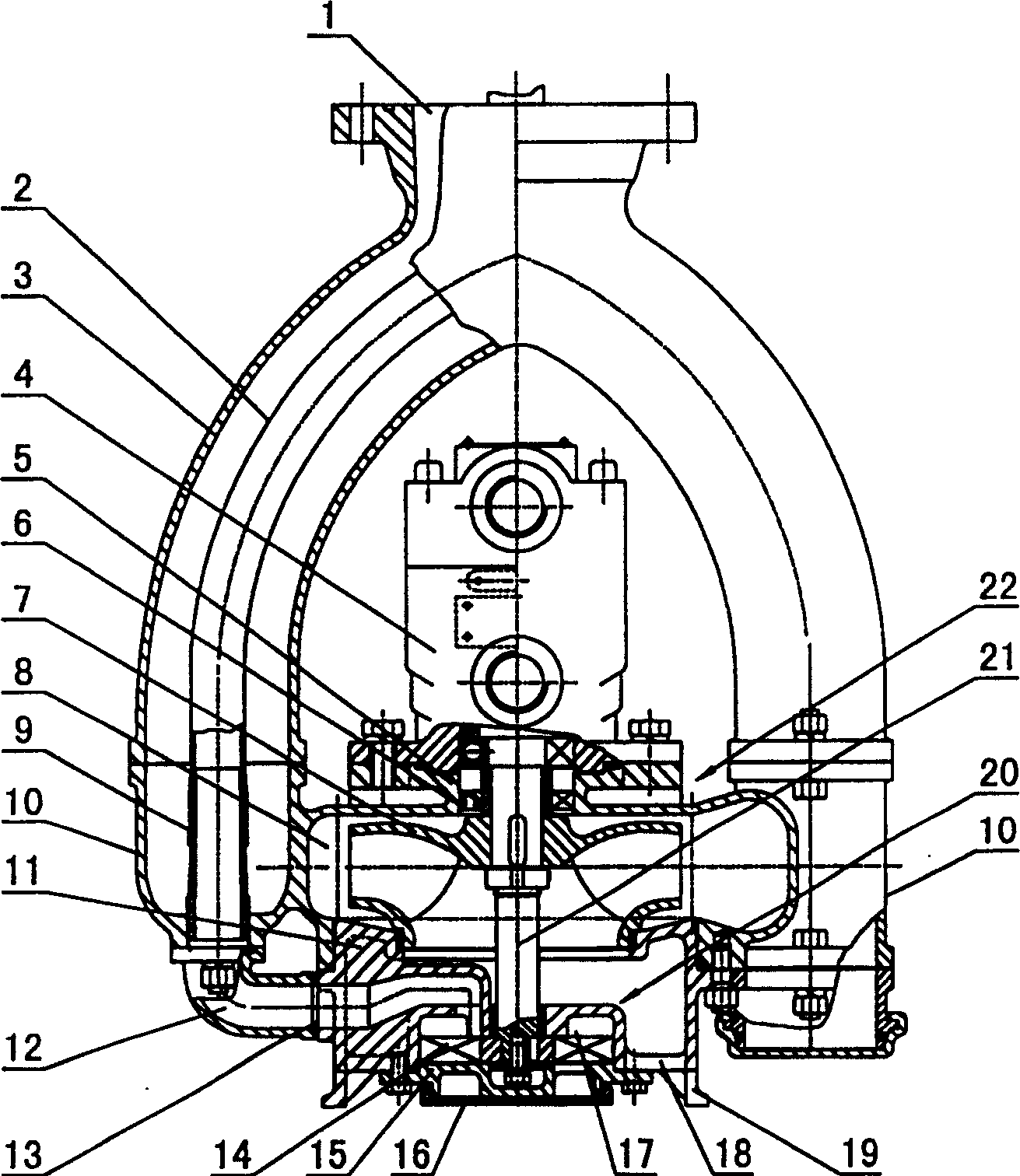

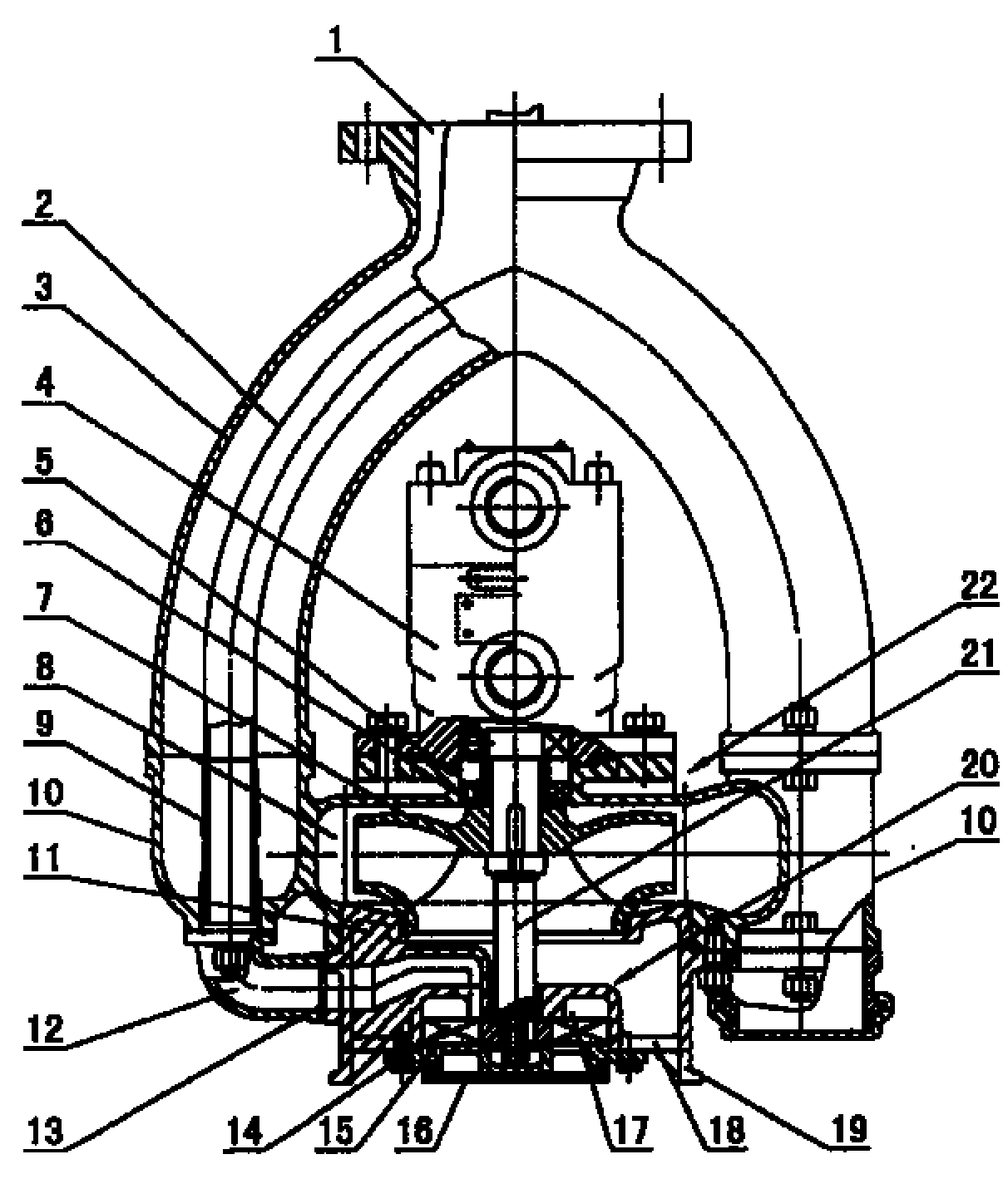

[0013] As shown in the figure, the present invention mainly includes a centrifugal pump 22, a vortex pump 20, a hydraulic motor 4 and an oil delivery pipe 3, wherein the hydraulic motor 4 is connected to the upper end of the centrifugal pump body 5, and the upper end of the vortex pump body 11 is embedded in the centrifugal pump body. The lower end of the body 5 is connected with the centrifugal pump body by bolts, thereby forming a centrifugal pump pressure chamber 8 in the centrifugal pump body; the vortex pump body is provided with a passage 18 for oil to enter the centrifugal pump pressure chamber, and the lower end of the passage It is the suction port of the centrifugal pump; the hydraulic motor shaft 21 passes through the centrifugal pump pressure chamber 8 and extends into the vortex pump pressure chamber 17, and the centrifugal pump impeller 7 located in the centrifugal pump pressure chamber is connected with the vortex pump impeller 14 located in the vortex pump pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com