Face mounting positive temp coofficient thermister and its manufacturing method

A technology of positive temperature coefficient and thermistor, which is applied in the direction of resistors with positive temperature coefficients, resistors, resistor parts, etc., can solve the problems of high cost and low strength of the box body, and prevent displacement and position Effect of moving and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

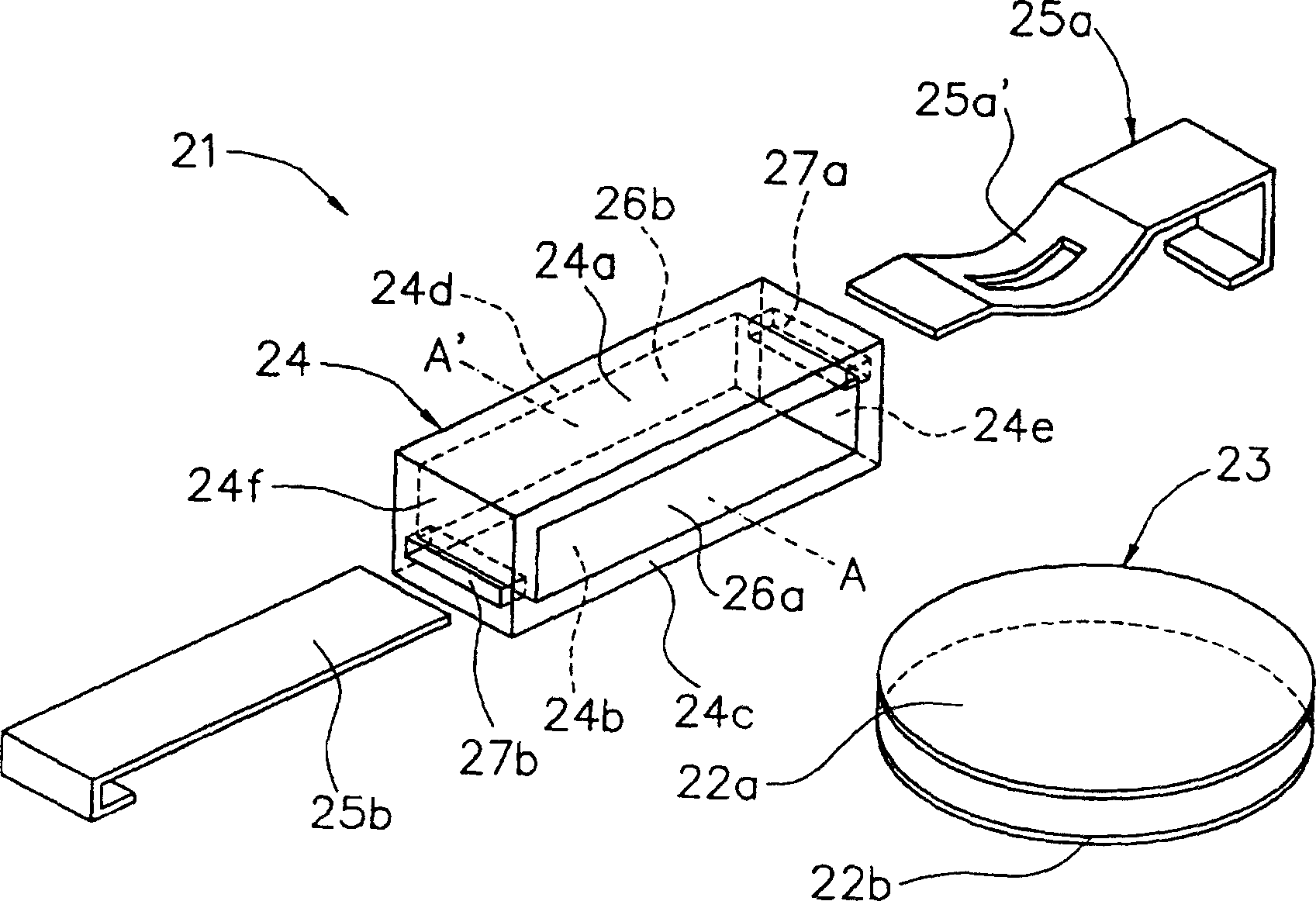

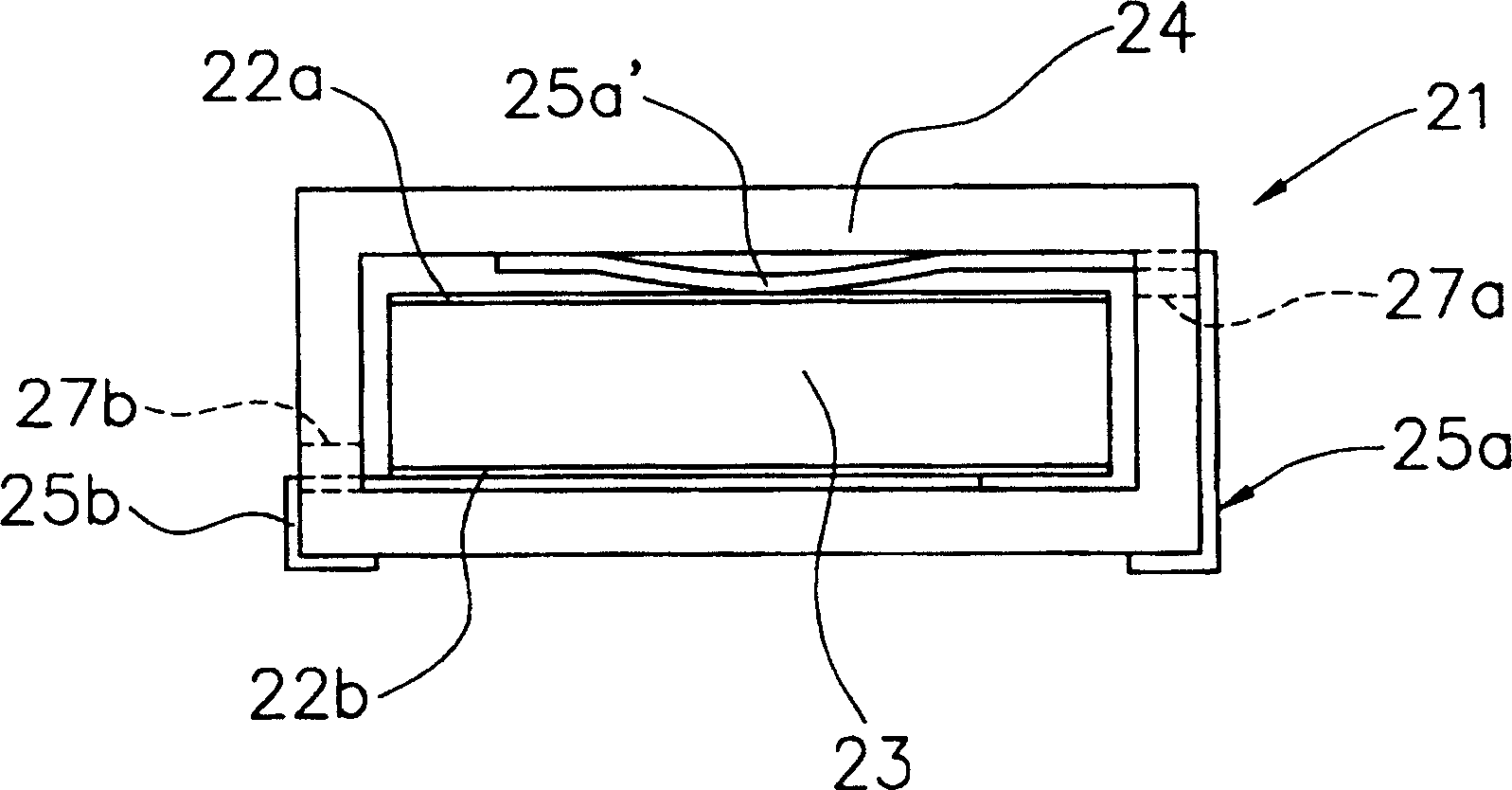

[0058] figure 1 It is an exploded perspective view showing a surface mount type PTC thermistor 21 according to an embodiment (Example 1) of the present invention. figure 2 It is a front view of the surface mount type PTC thermistor 21 .

[0059] The surface mount type positive temperature coefficient thermistor 21 consists of a plate-shaped positive temperature coefficient thermistor 23 formed with electrodes 22a, 22b on two opposite main surfaces; Box 24; a pair of metal terminals that are electrically connected to the two main surface electrodes 22a, 22b of the positive temperature coefficient thermistor element 23 in the inner space, and sandwich the positive temperature coefficient thermistor element 23 25a, 25b composition.

[0060] In the positive temperature coefficient thermistor element 23, electrodes 22a and 22b are formed on both main surfaces of a disc member having a diameter of 8 mm and a thickness of 2 mm.

[0061] The insulating box 24 is made of PPS (para...

Embodiment 2

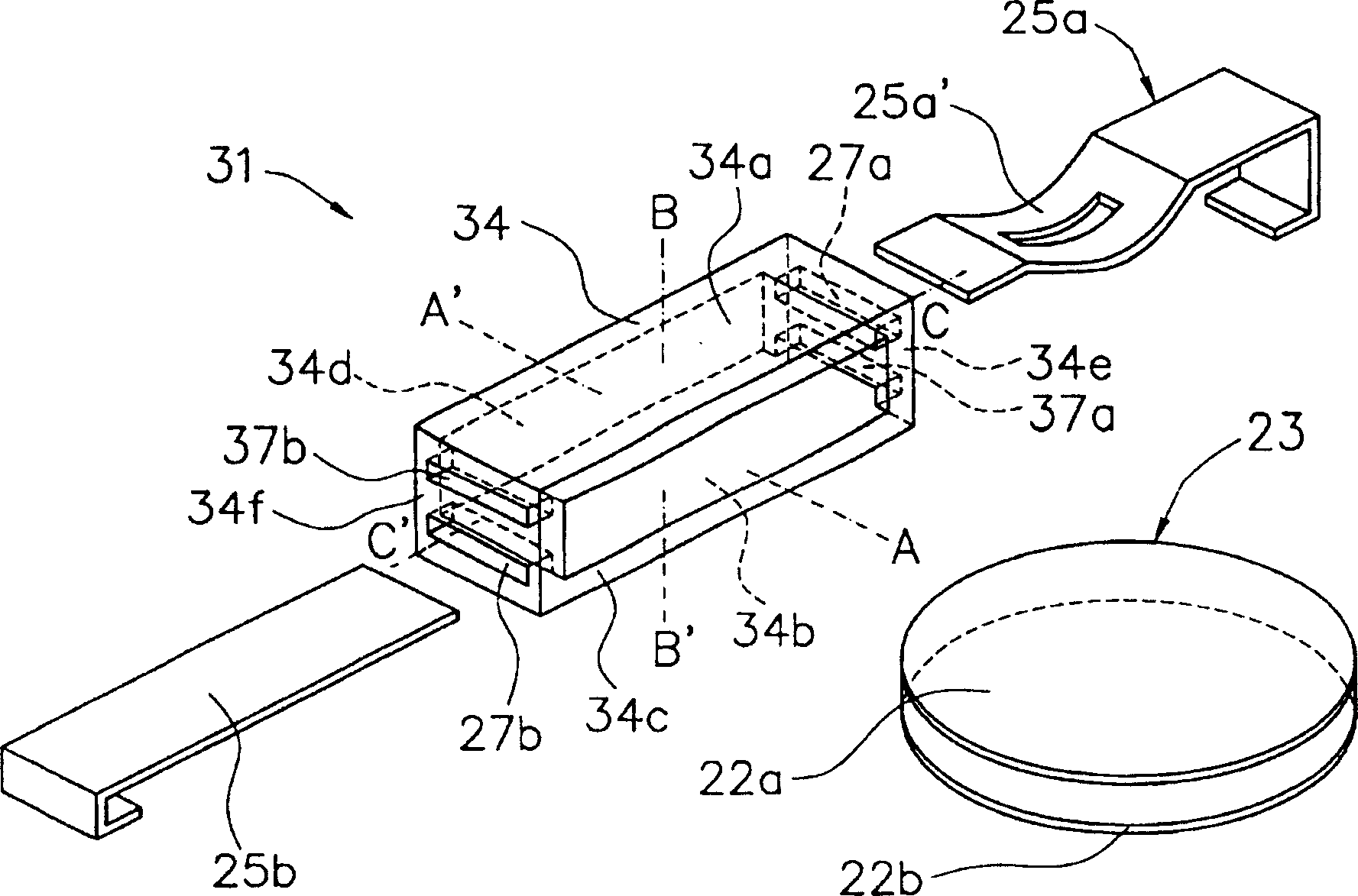

[0075] image 3 It is an exploded perspective view showing a surface mount type PTC thermistor 31 of another example (Example 2) of the present invention.

[0076] Since the surface mount type positive temperature coefficient thermistor 31 is the same as the surface mount type positive temperature coefficient thermistor 21 of Embodiment 1 except for the structure of the insulating case 34, the same symbols are used for the same parts, And omit detailed description.

[0077] The insulating case 34 of the surface mount type positive temperature coefficient thermistor 31 has terminal insertion holes 27a, 37a and 27b, 37b at two positions respectively formed on a pair of end faces 34e, 34f facing each other. The terminal insertion holes 27a, 37a and 27b, 37b are in the center of a pair of main faces 34a, 34b, a pair of opening sides 34c, 34d, and a pair of end faces 34e, 34f of the insulating case 34 as the axis B-B' and the axis A-A'. And axis C-C', formed by rotating 180 degre...

Embodiment 3

[0080] Figure 4 It is a perspective view showing a surface mount type positive temperature coefficient thermistor 51 of another example (Example 3) of the present invention. Figure 5 It is a plan view showing the insulating case 54 of the surface mount type positive temperature coefficient thermistor 51 .

[0081] Since the surface mount type positive temperature coefficient thermistor 51 is the same as the surface mount type positive temperature coefficient thermistor 21 of Embodiment 1 except for the structure of the insulating case 54, the same symbols are attached to the same parts, And omit detailed description.

[0082] The insulating case 54 of the surface mount type positive temperature coefficient thermistor 51 is formed with an extension 58a extending from one main surface 54b to the opening side 54c and an extension 58b extending from one main surface 54b to the opening side 54d. Protruding portions 59a and 59b are formed at the tips of the portions 58a and 58b,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com