On-line below intermediate temp. cooling system of plate

A cooling system, medium temperature technology, applied in cooling beds, metal processing equipment, metal rolling, etc., can solve the problems of restricting the production and development of special plates and low-alloy plates, insufficient cooling capacity of steel plates, and inability to achieve rapid cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

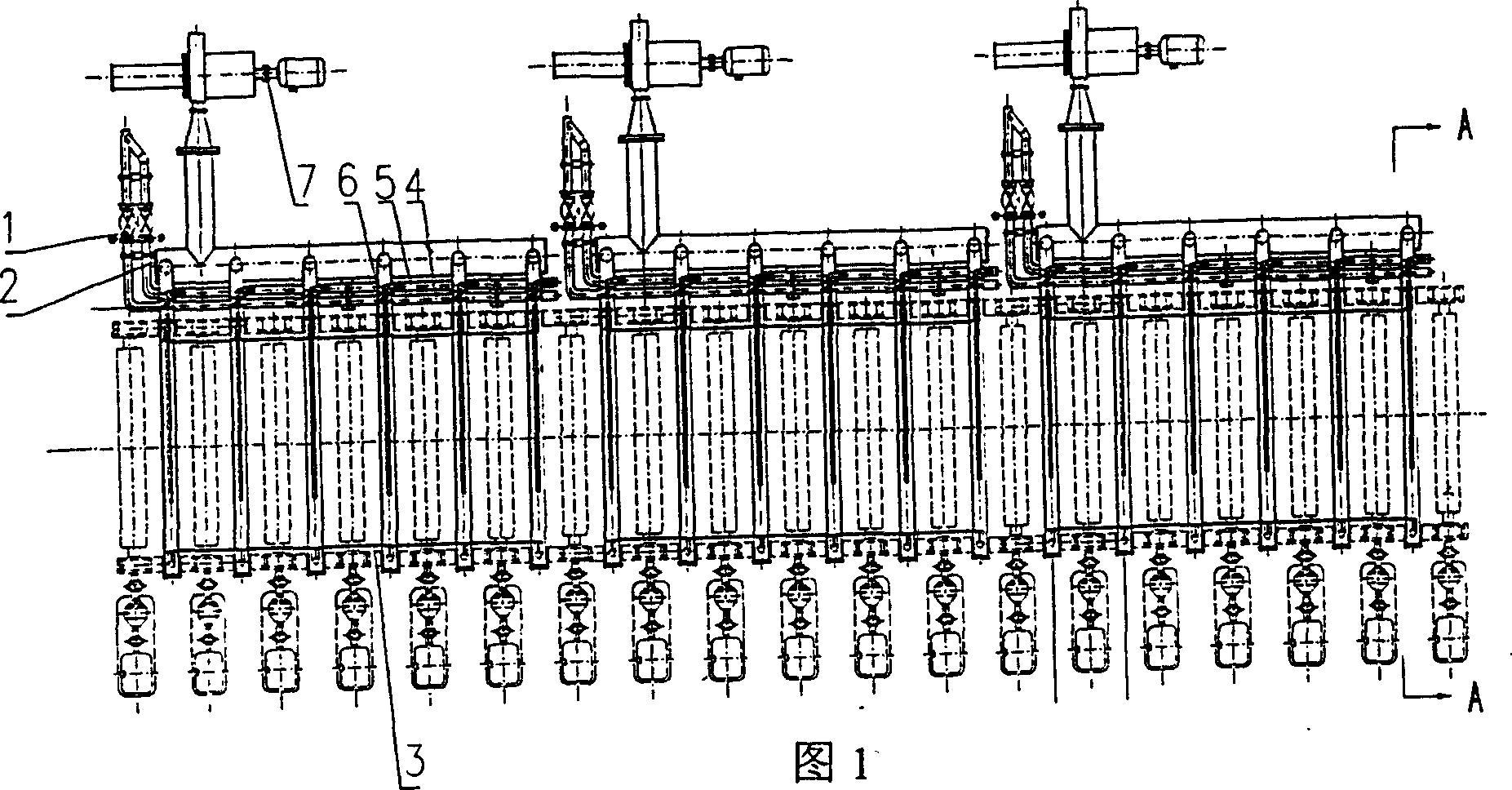

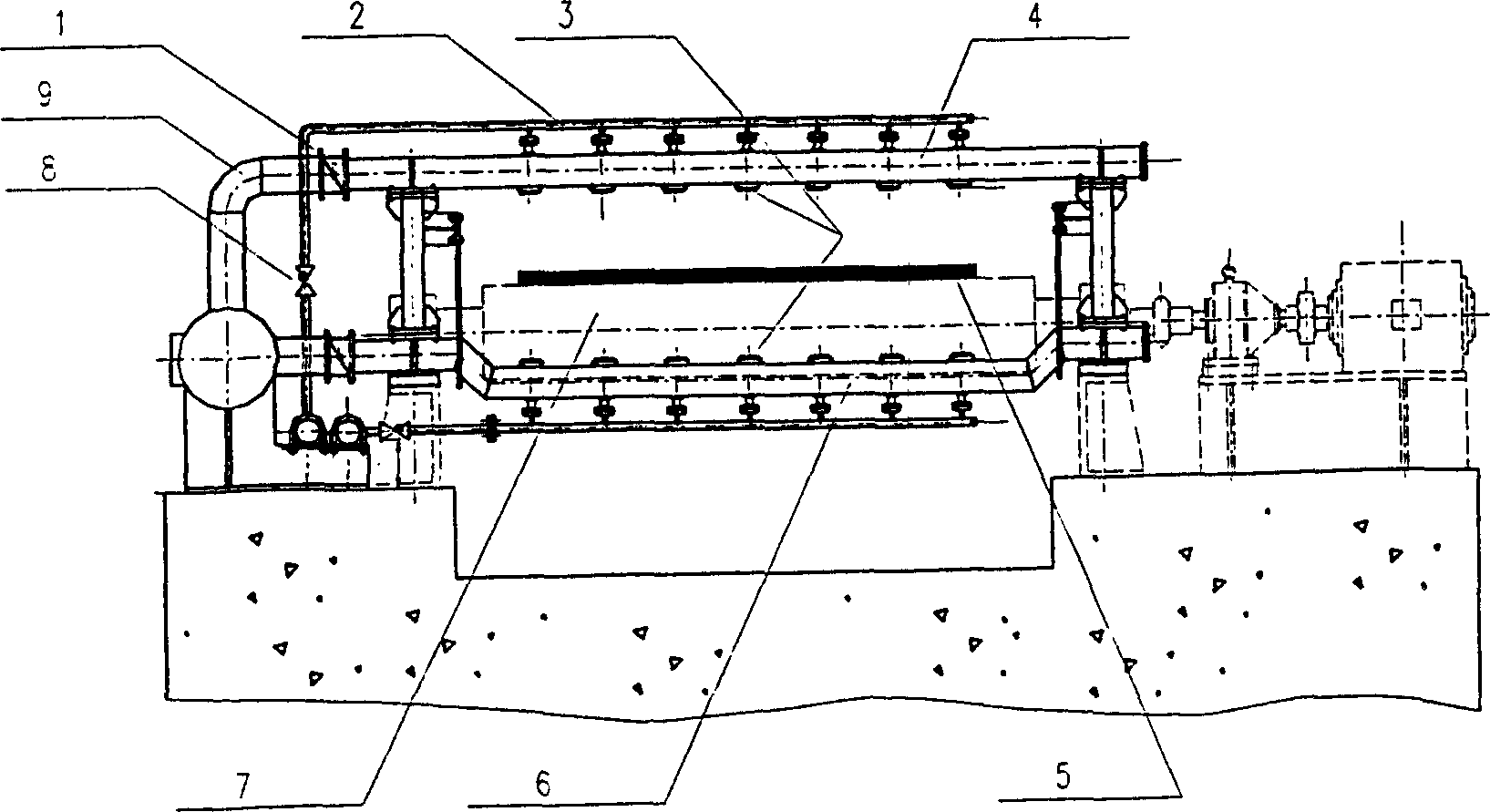

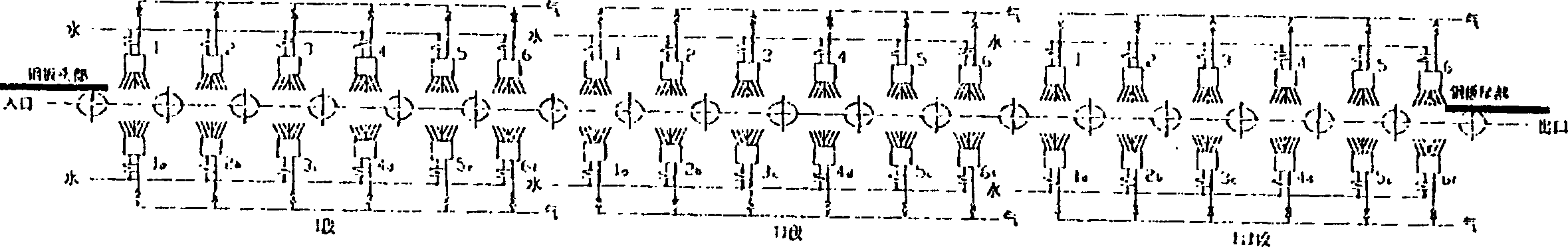

[0010] Fig. 1 is the plan layout diagram when the steel plate of the present invention is cooled, is made of several monomer equipments, the structure and attachment of each monomer equipment figure 2 Same as shown. It can be seen from the figure that the motor drives the conveying roller table to move, the steel plate is placed on the conveying roller table, and the steam-mist cooling device is installed on the upper and lower sides of the conveying roller table. The water quantity regulating valve 8 is installed on the pipe 2, the nozzle 3 is installed on the spray pipe 4, the spray pipe 4 is connected with the air supply pipe 9, the high-pressure fan is connected with the air supply pipe 9, and the water supply pipe 2 is connected with the spray pipe 4. Adjust the air pressure, air volume, water pressure, water temperature, cooling speed, etc. according to the specifications of the steel plate to be cooled. For example, if the thickness of the steel plate is 20mm, the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com