Blue dye composition preparation and use

A blue dye and composition technology, applied in the direction of organic dyes, dyeing methods, textiles and paper making, etc., to achieve the effects of dyeing reproducibility and levelness improvement and good color giving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

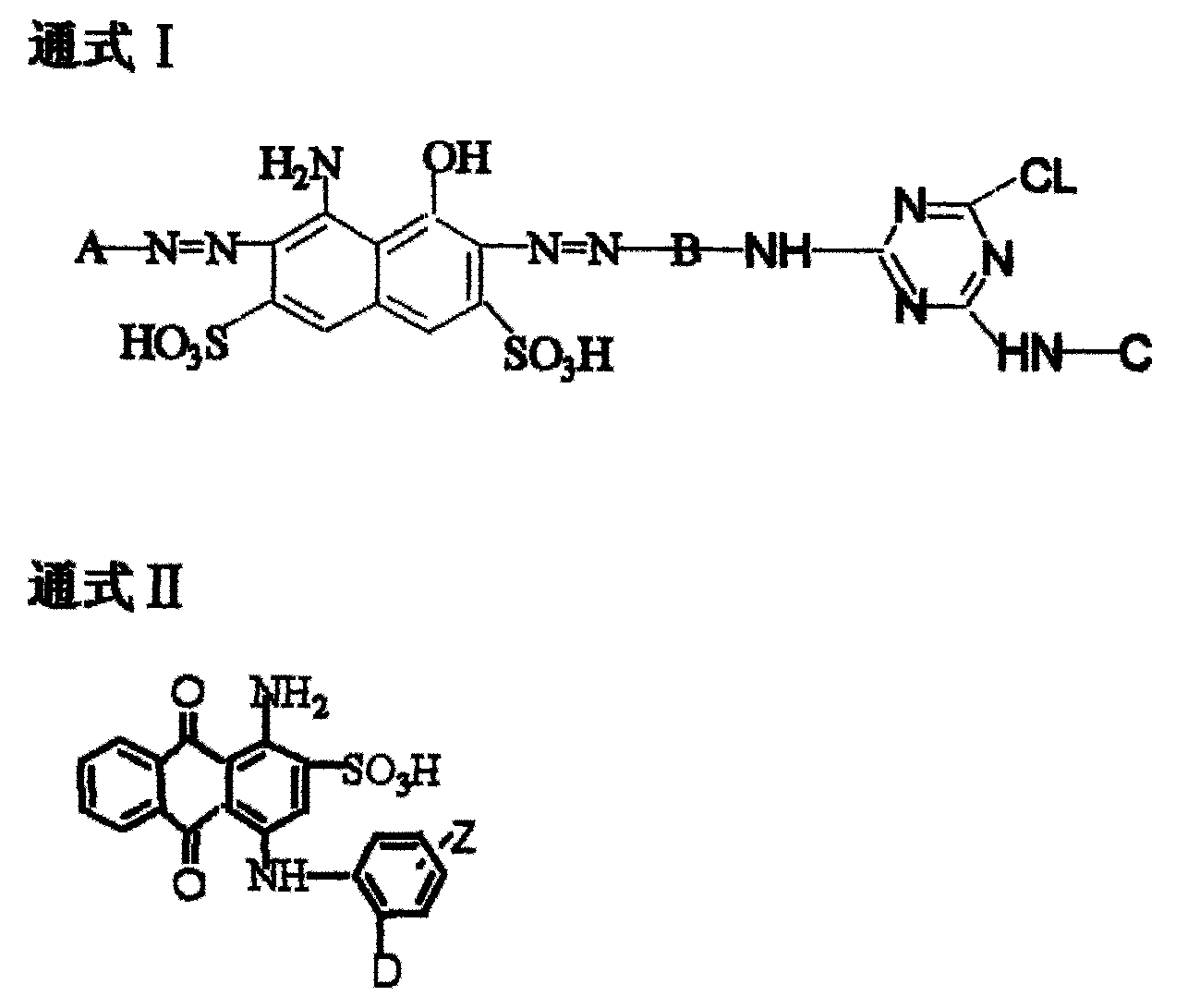

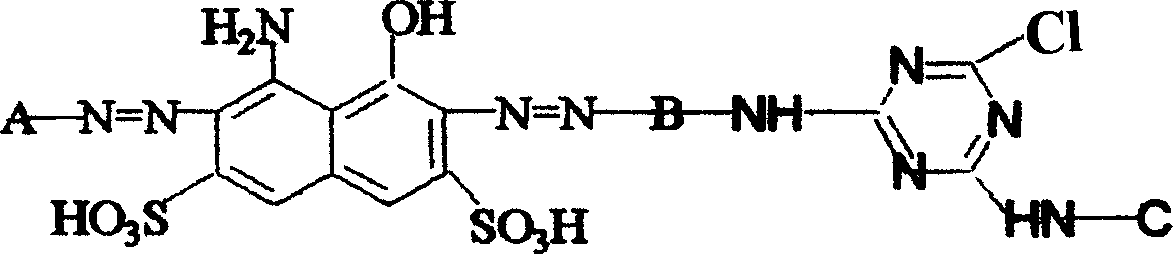

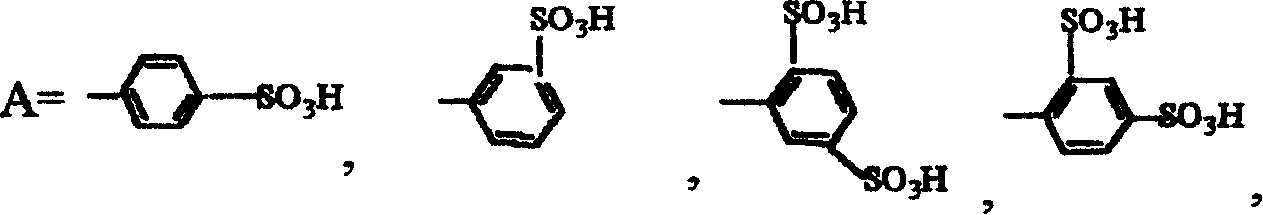

Method used

Image

Examples

Embodiment 1

[0071]Take 20 parts of the above-mentioned dyes of the formula III conforming to the general structural formula I, 20 parts of the dyes of the formula XII, 40 parts of the dyes of the formula XXX conforming to the general structural formula II, and 20 parts of the dyes of the formula XXXII, and fully mix them with each other to form a uniform dye composition. Then dye or print on the cotton fiber fabric with the following example method to obtain a blue color with uniform color, good lifting performance, bright color and excellent light fastness.

[0072] 1. Dip dyeing (exhaustion dyeing)

[0073] Dye bath formula: 2-6% of the above-mentioned combined dyes (to the weight of cotton fabric), 60 grams per liter of sodium sulfate, 20 grams per liter of soda ash, and a bath ratio of 1:20.

[0074] Dyeing process steps: dissolve 1-3 parts of the above-mentioned combined dyes with appropriate amount of water, then add 600 parts of 10% (weight %) Yuanming powder liquid, and finally ad...

Embodiment 2

[0079] Take 20 parts of the above-mentioned dyes of the formula V and 20 parts of the dyes of the formula XVI conforming to the general structural formula I, and 40 parts of the dyes of the XXIX and 20 parts of the dyes of the formula XXXII conforming to the general structural formula II, and fully mix them with each other to form a uniform dye composition, and then press The exhaust dyeing and printing method of Example 1 is used for dyeing and printing on cotton fabrics, and can obtain bright blue-dark blue with uniform coloring, excellent fastness, and green light.

Embodiment 3

[0081] Take 20 parts of the dyes of the formula XII and 20 parts of the dyes of the formula XXII conforming to the general structural formula I, and 40 parts of the dyes of the formula XXXI and 20 parts of the dyes of the formula XXXII conforming to the general structural formula II, and fully mix them with each other to form a uniform dye composition. Then carry out dyeing or printing on the cotton fabric according to the exhaust dyeing and printing method of embodiment 1, can obtain the vivid blue-dark blue of even color giving, good fastness, slightly red light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com