High pressure low volume pump

A small-capacity, high-pressure technology, applied in the direction of variable-capacity pump components, pumps, piston pumps, etc., can solve problems such as fragile, easy to break, and difficult to avoid precision small piston breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

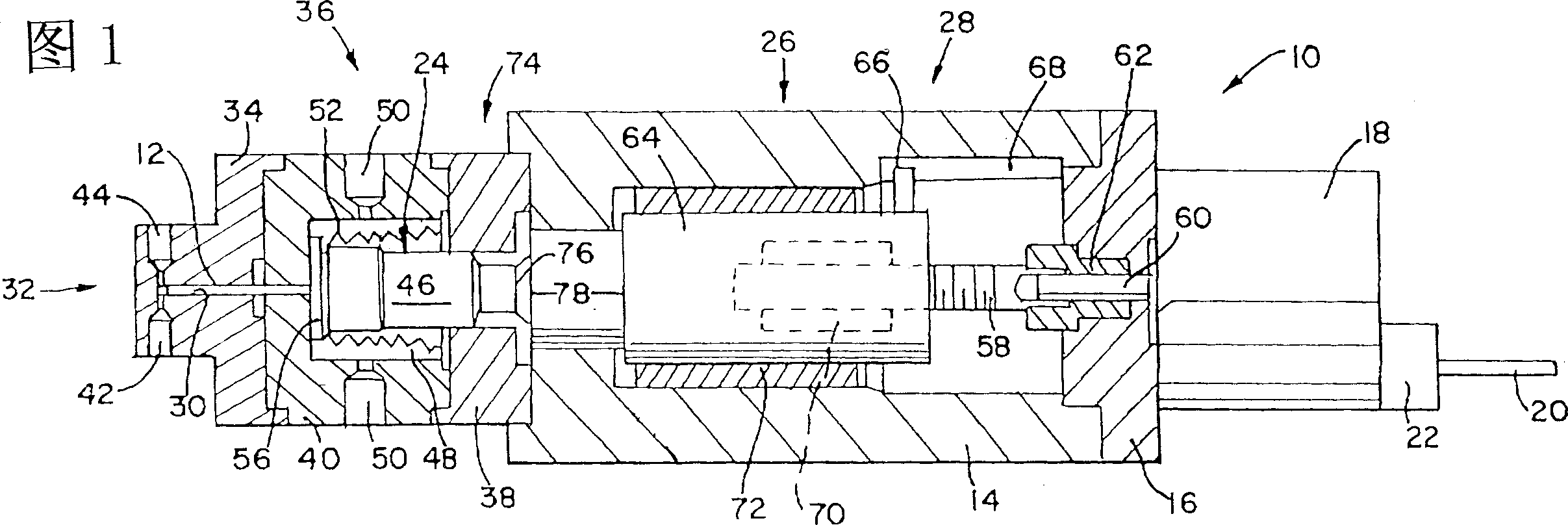

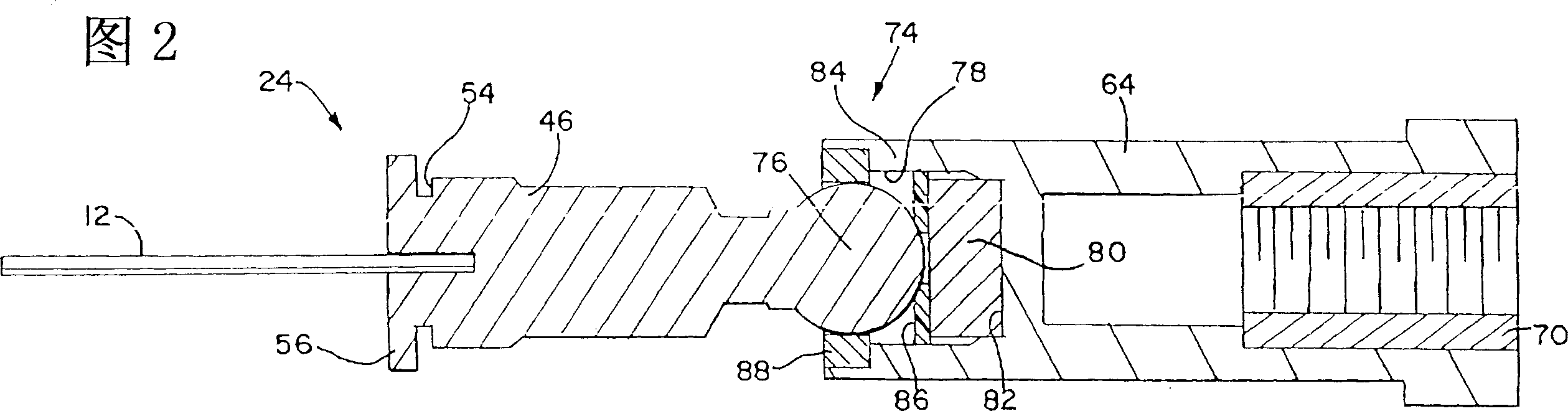

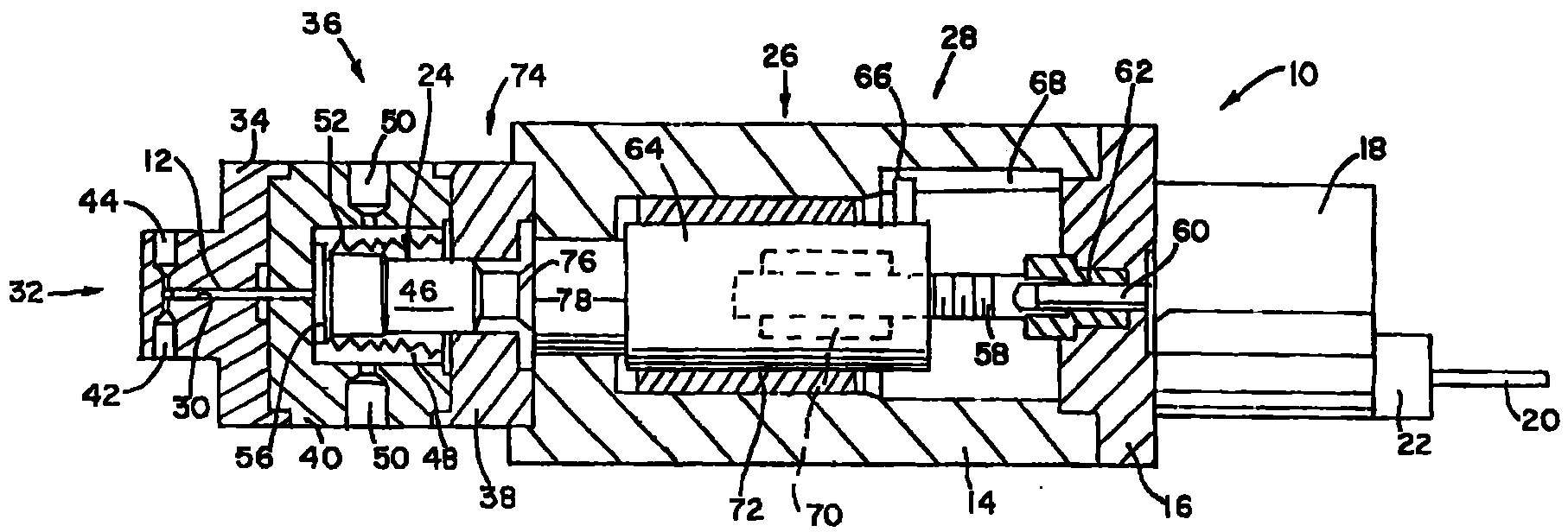

[0009] Referring now to the drawings, in Figure 1, there is shown a high pressure small volume pump generally indicated at 10 and constructed in accordance with the principles of the present invention. During high pressure liquid chromatography analysis, the pump 10 is used to provide a solvent liquid mobile phase, and at a pressure of at least 600 bar at the highest, the solvent is pumped out at a small flow rate of about 50 nanoliters to about 250 microliters per minute, such as Methanol, isopropanol, acetonitrile, etc.

[0010] To achieve these desirable performance characteristics, pump 10 therefore includes a piston 12 in the form of an elongated rod having a diameter of less than about 10 millimeters, and preferably its diameter is from about 1 millimeter to about 3 millimeters. Piston 12 is formed from a crystalline material, preferably sapphire, or a material having similar properties (eg, a mineral), preferably zircon. An advantage of these materials is that they can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com