High vacuum low temperature thermostat using low temperature leak flexible connecting structure

A cryostat, flexible connection technology, applied in heat exchanger sealing devices, irreversible cycle compressors, heat exchange equipment, etc., to reduce axial heat leakage, reduce contact thermal resistance, and increase thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

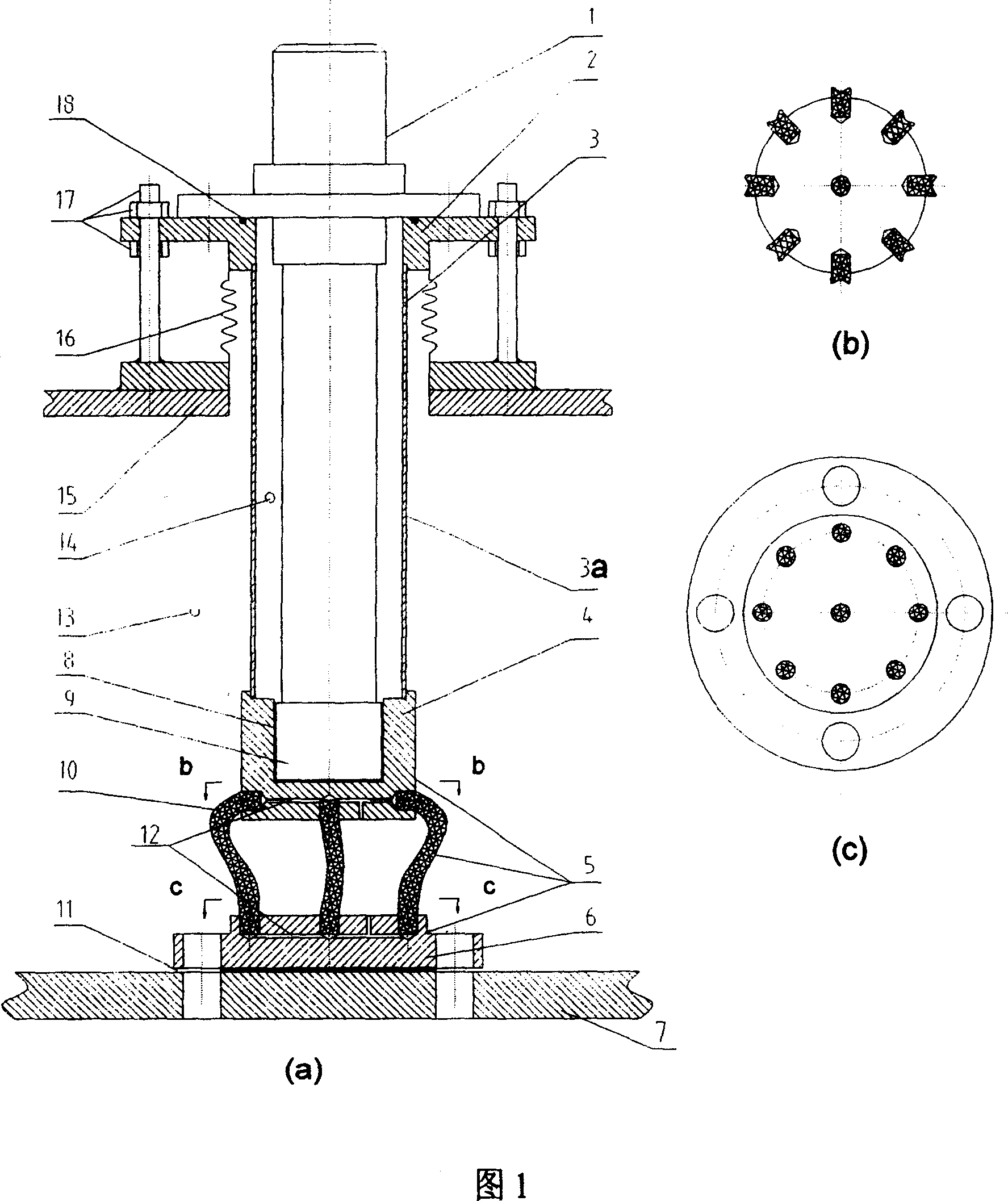

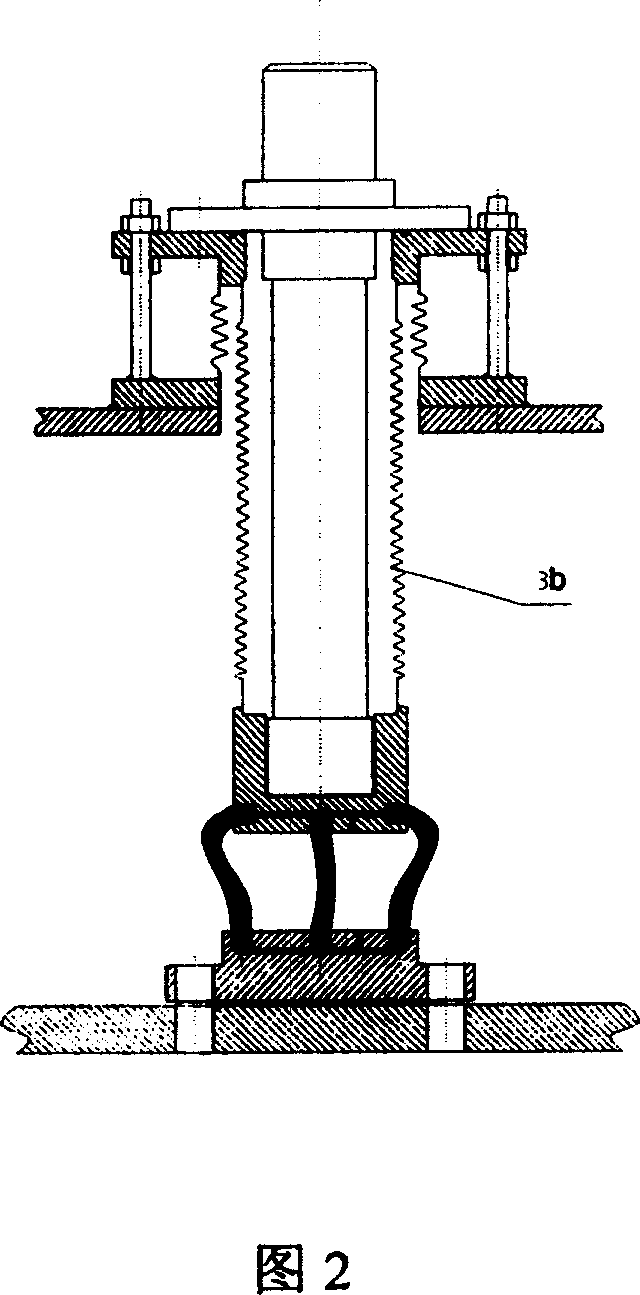

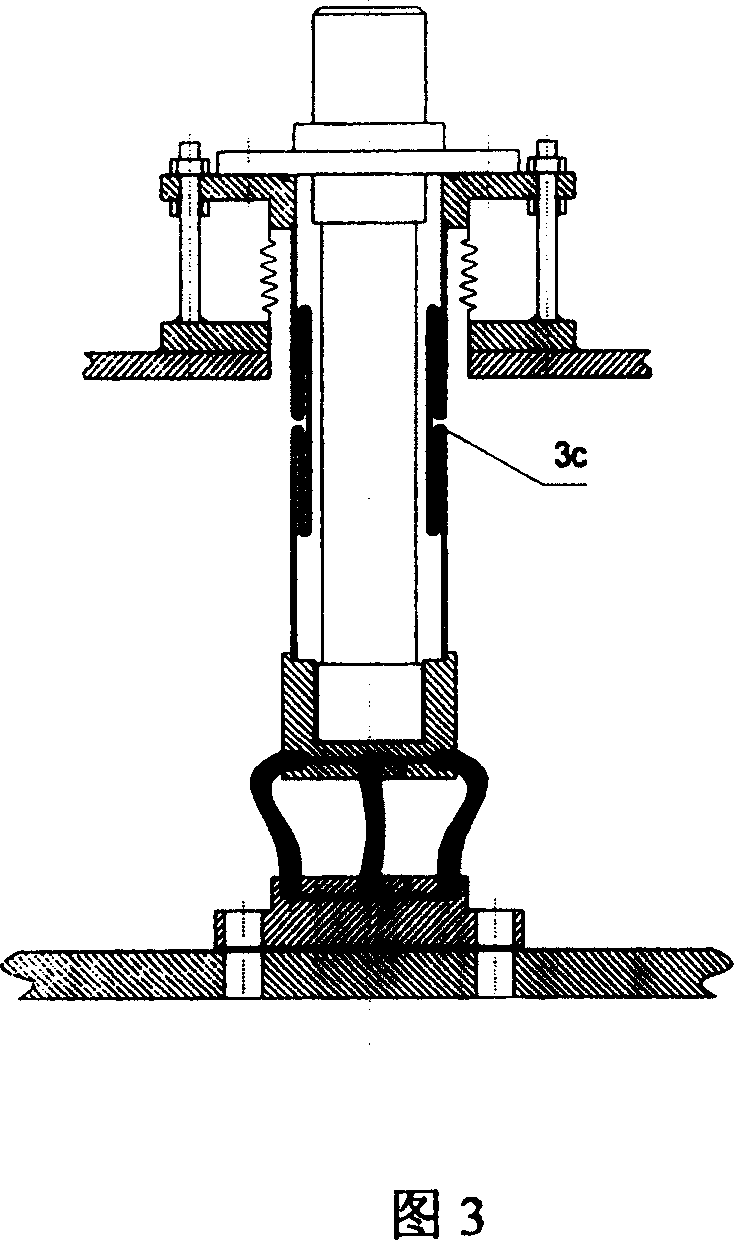

[0011] In order to achieve the purpose of low heat leakage, the present invention adopts three schemes in terms of vacuum jacket, that is, thin-walled stainless steel tube, corrugated tube and folded sleeve. The thin-walled tube solution (Fig. 1-3a) is to increase the heat conduction resistance through the thin-walled tube, while the common point of the corrugated tube (Fig. 2-3b) and the folded sleeve (Fig. 3-3c) is to increase the heat conduction path to achieve The purpose of reducing axial heat leakage. The latter two solutions are more suitable for occasions where the cooling temperature is relatively low, because at this time, reducing heat leakage and effectively utilizing the cooling capacity of the refrigerator are the key problems to be solved in the system. At the same time, since the contact thermal resistance between the cold head and the heat sink and between the heat sink and the object to be cooled will lead to an increase in the temperature difference between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com