On-line automatic controlsystem for printing quality

An automatic control system and printing quality technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problems of printing quality inspection, scrapped printed products, etc., and achieve the effect of high conformity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

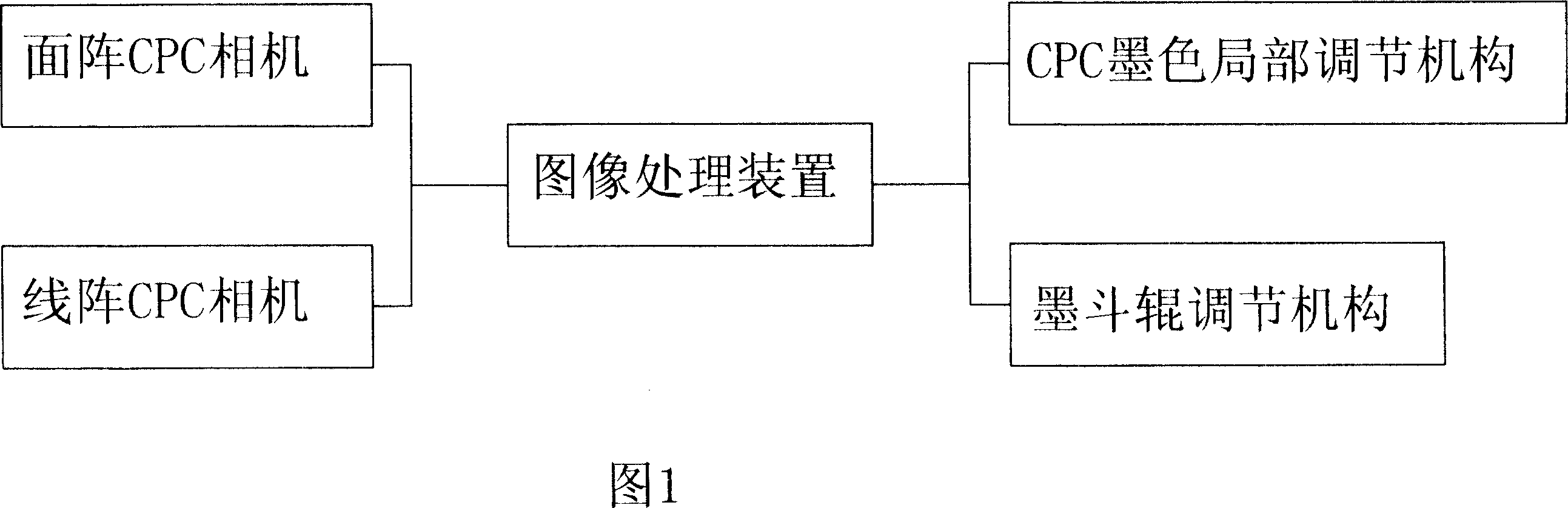

[0010] As shown in Figure 1, the linear array CCD camera and the area array CCD camera collect image information and transmit it to the image processing device. The image processing device contains standard proof image information. By comparing the collected image information with the standard proof image information, the The comparison result is used as a control signal to feed back to the ink fountain roller adjustment mechanism and the local ink color adjustment mechanism to adjust the overall and local ink color respectively, so as to realize the online automatic control of the printing quality of the printed matter.

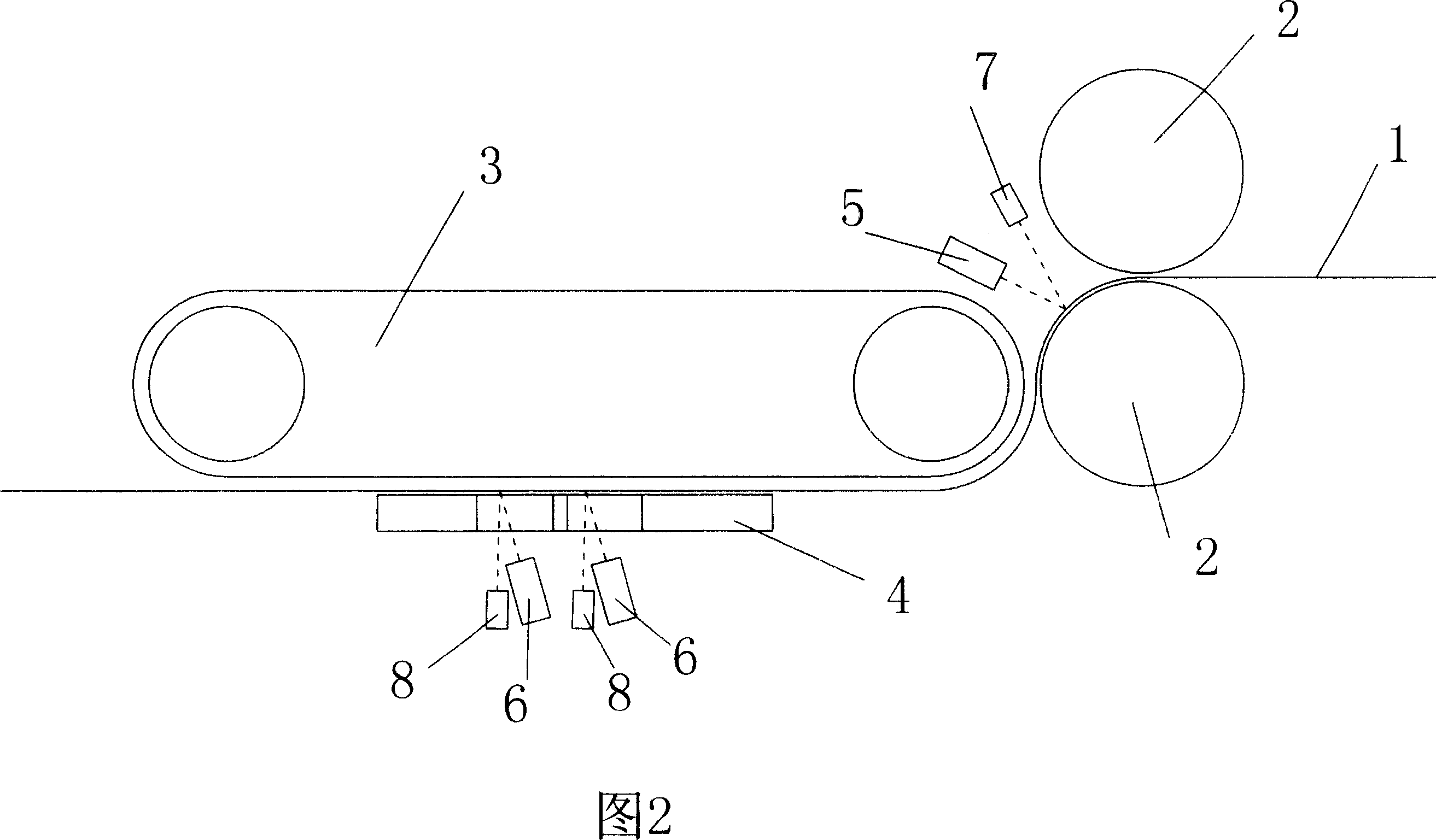

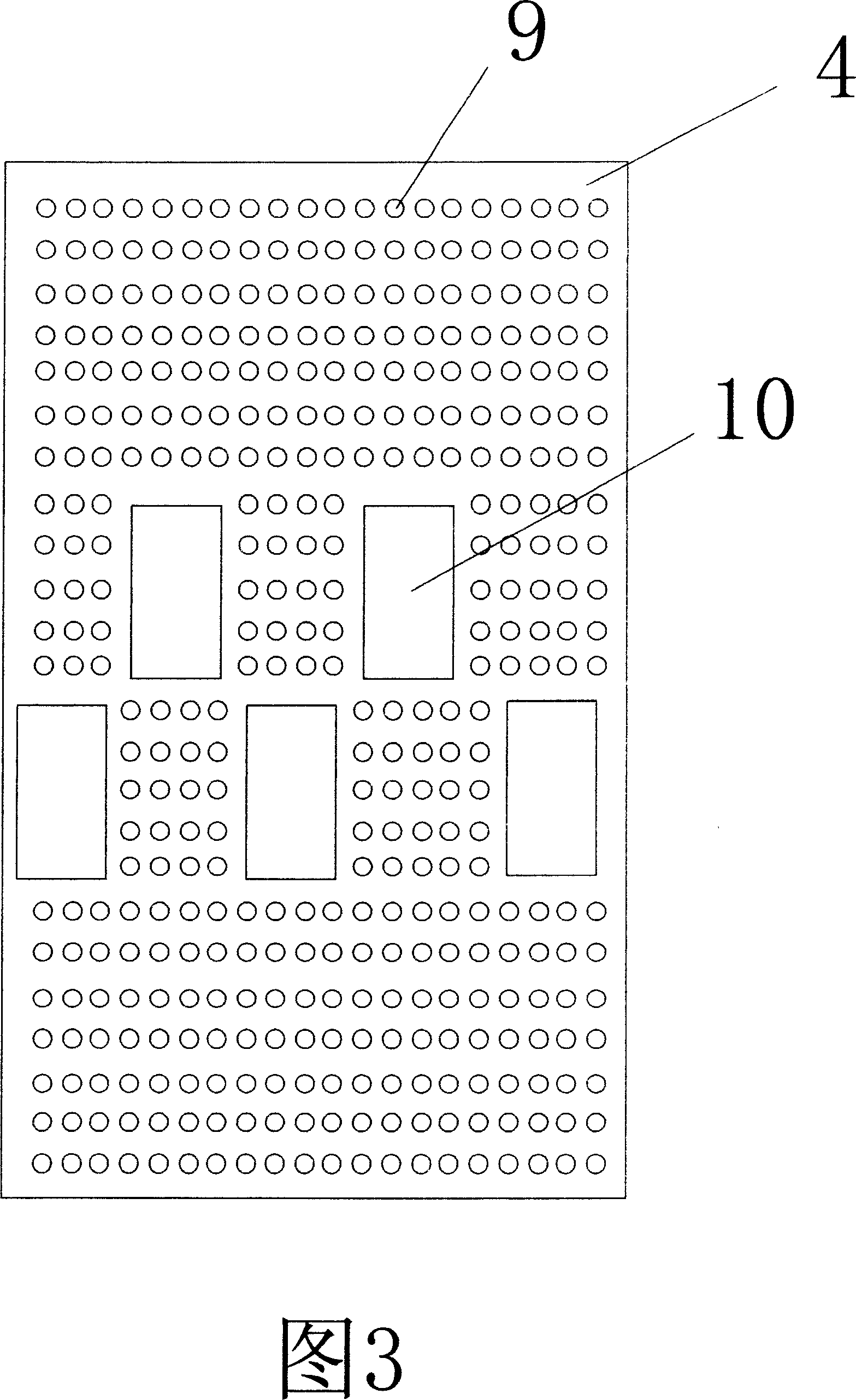

[0011] As shown in FIG. 2 and FIG. 3 , the printed product 1 is conveyed to the printing cylinder 2 by the paper supply device for printing, and then conveyed to the next process by the paper conveying device 3 . The linear array CCD camera 5 and the lighting source 7 are located next to the printing cylinder 2. Since the linear flatness of the width directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com