Laser laser transfer printing machine

A laser laser, printing machine technology, applied in rotary printing machine, printing machine, transfer printing and other directions, can solve the problems of waste, film damage, etc., to achieve the effect of prolonging life, reducing cost and isolating dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

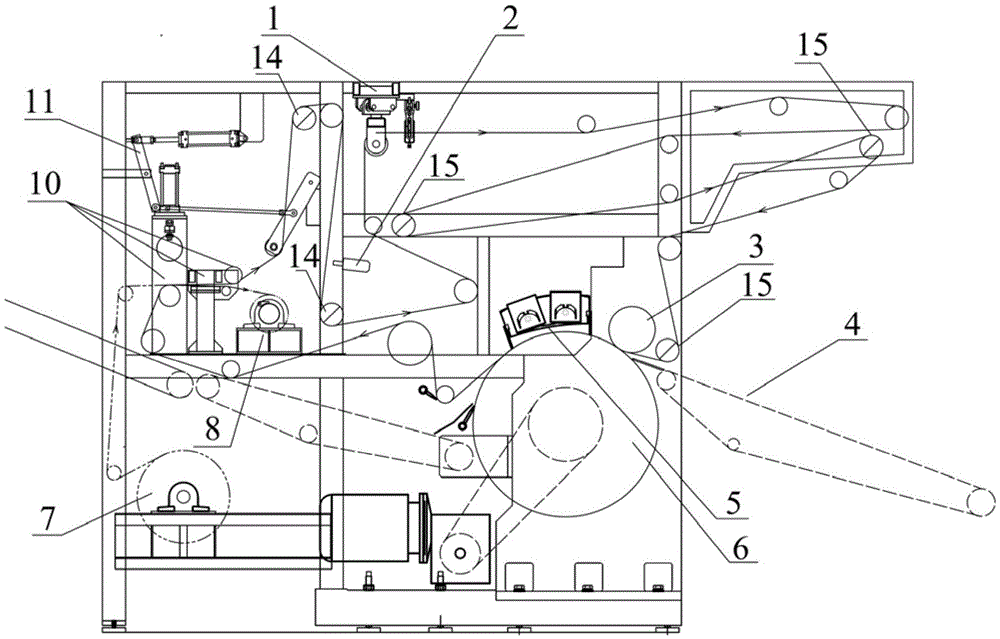

[0031] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

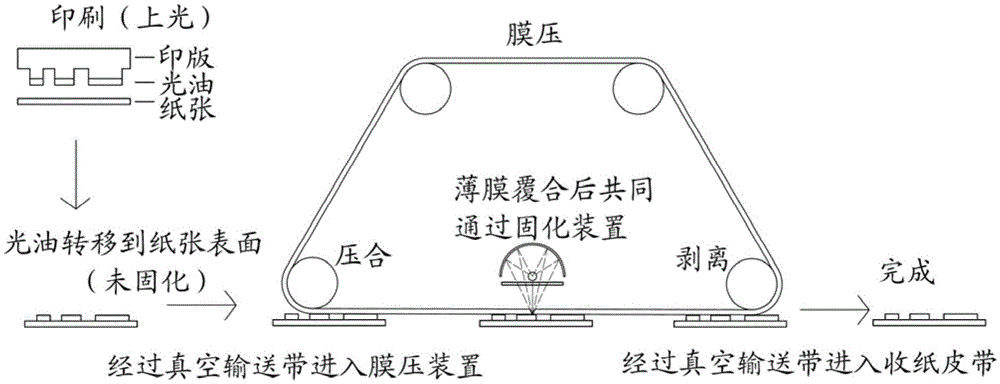

[0032] like figure 1 Shown is a schematic diagram of the working process of the laser transfer printing machine.

[0033] The paper coated with varnish enters the film pressing device from the right paper feeding belt, and is pressed together by the controllable eccentric roller to compound the paper and the pretreated film. After the two pass through the UV curing device together, the ink on the surface of the paper is cured. Then the paper is separated from the film, and then the paper is driven by the delivery belt into the delivery unit for collection, while the film is recycled in the upper part.

[0034] UV curing device generally refers to a device that uses ultraviolet rays to cure coatings, paints, inks and other substances.

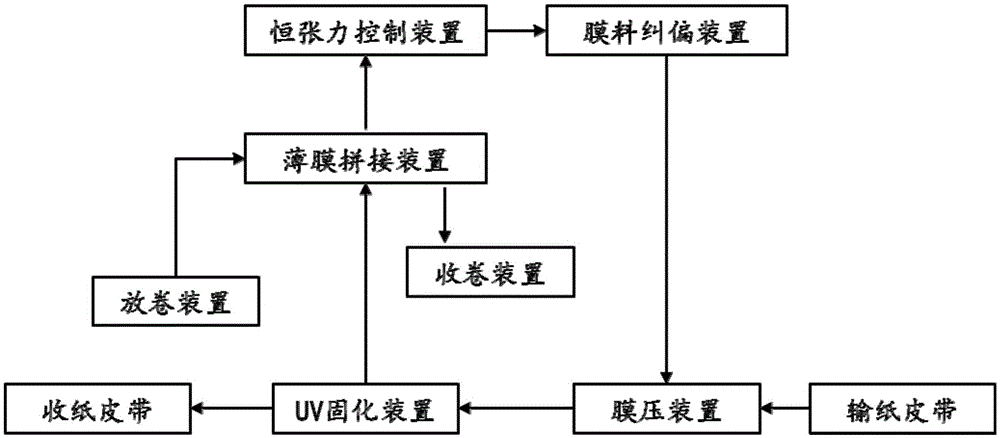

[0035] like figure 2 Shown is the structural block diagram of the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com