Precision machining apparatus and method for axial symmetry rotary curve

A surface of revolution, precision machining technology, applied in metal processing equipment, machine tools suitable for grinding workpiece planes, manufacturing tools, etc., can solve the problem that the surface accuracy of the sidewall forming curved surface cannot meet the higher requirements, and affects radial tire products. Smoothness and eccentricity, affecting the stiffness and eccentricity of radial tire products, etc., to achieve the effect of reducing manual grinding and polishing, facilitating processing programming, and reducing the roughness of the machined surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

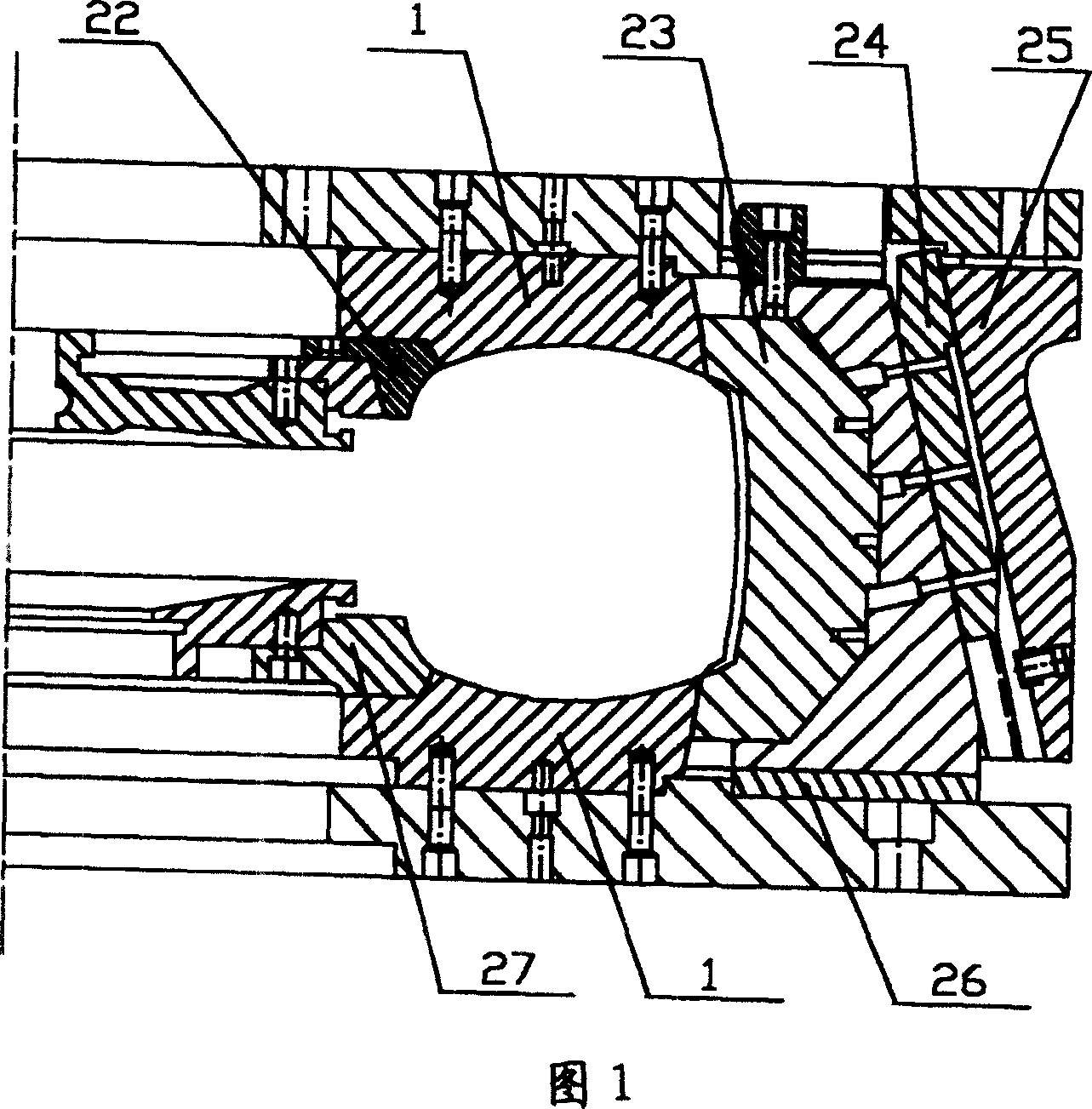

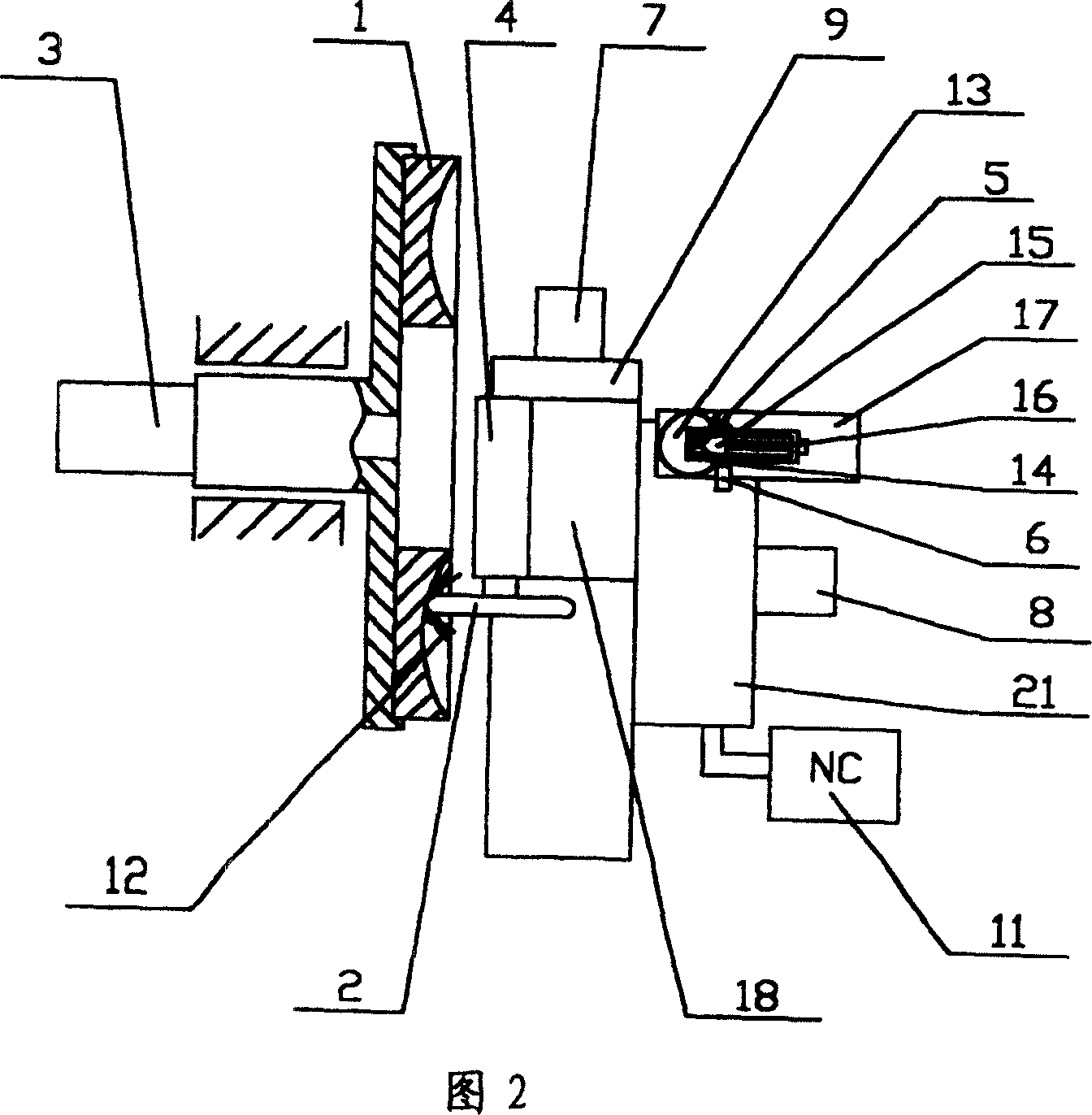

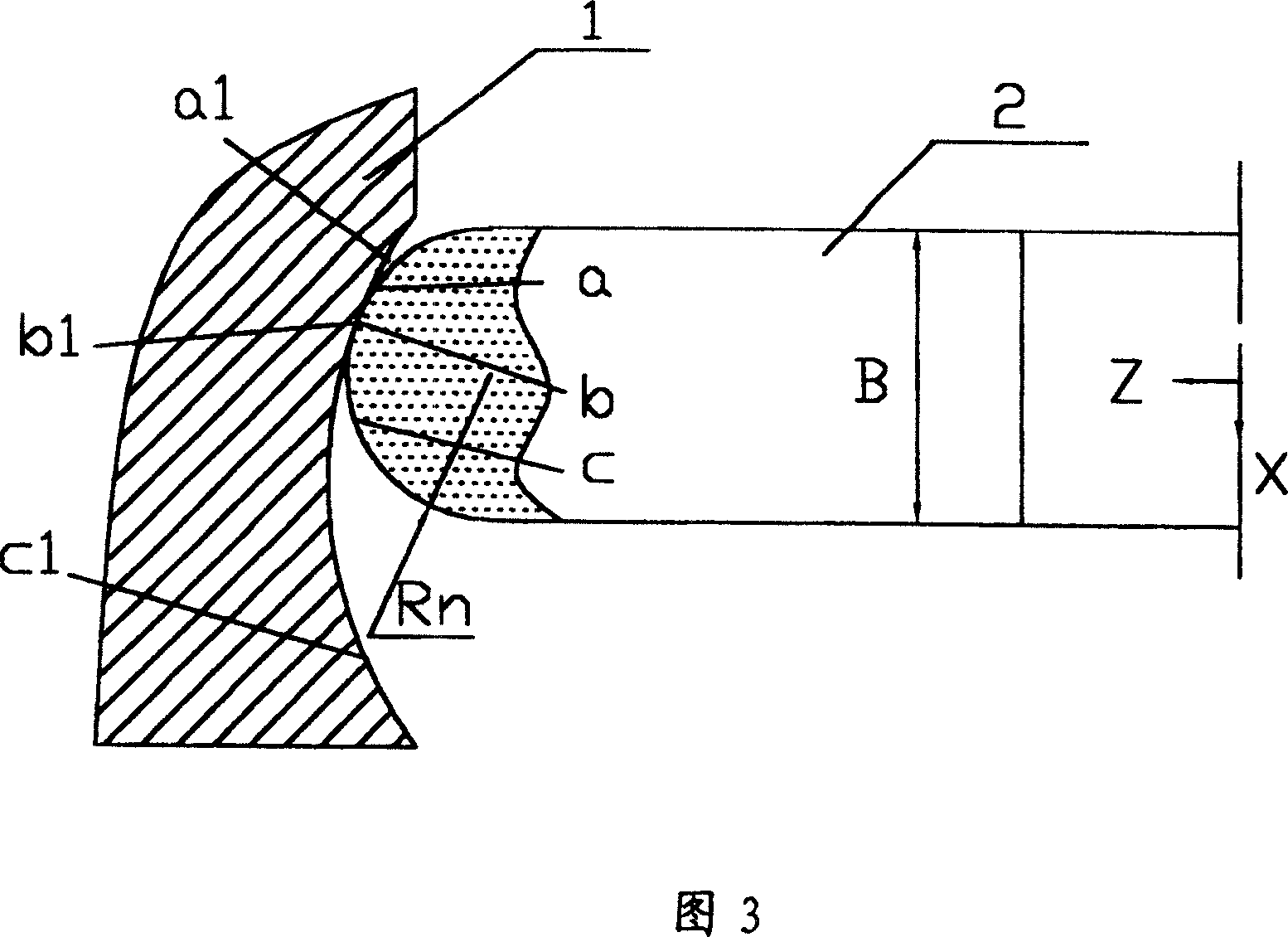

[0035]The present invention is used for the processing of the workpiece 1 having the curved surface of revolution as the axisymmetric molding surface of the side plate of the radial tire active mold. The processing device is shown in Figures 2 and 3, which includes an arc-shaped grinding wheel 2, a workpiece rotary drive spindle 3, Grinding wheel rotation drive spindle 4, A-axis servo motor 7 perpendicular to / parallel to the workpiece rotation drive spindle, B-axis servo motor 8 perpendicular to A axis, A-axis table 9, B-axis table 10, The two-axis linkage numerical control device 11, the grinding wheel rotary spindle mounting base 18, the grinding machine bed 21, the workpiece 1 with the rotary curved surface is clamped on the rotary drive spindle 3 for rotary feed movement, and the arc-shaped grinding wheel 2 is installed on the high-speed rotation The shaft end of the grinding wheel rotary driving main shaft 4, the grinding wheel rotary driving main shaft 4 is installed on t...

Embodiment 2

[0045] The present invention is used to process the workpiece 1 having an axisymmetric convex surface shape, its structure is shown in Figure 8, its grinding process and grinding wheel dressing process are the same as in Embodiment 1, only need to appropriately change the numerical control processing program, then Grinding of workpieces with axisymmetric convex surfaces can be realized.

Embodiment 3

[0047] The present invention is used to process the workpiece 1 with a combined shape of axisymmetric convex-concave surface. Its structure is shown in Figure 9. When the grinding wheel 2 is used, the installation structure of embodiment 1 or embodiment 2 will produce collision and interference between the grinding wheel rotary drive spindle 4 and the workpiece 1. For this reason, the axes of the arc-shaped grinding wheel 2 and the grinding wheel rotary drive spindle 4 must be inclined at a certain angle. The rotary table 13 of the grinding wheel dressing tool is inclined at the same angle in the same direction at the same time, so that the workpiece with an axisymmetric convex-concave composite surface or a relatively deep axisymmetric concave curved surface can be ground. same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com