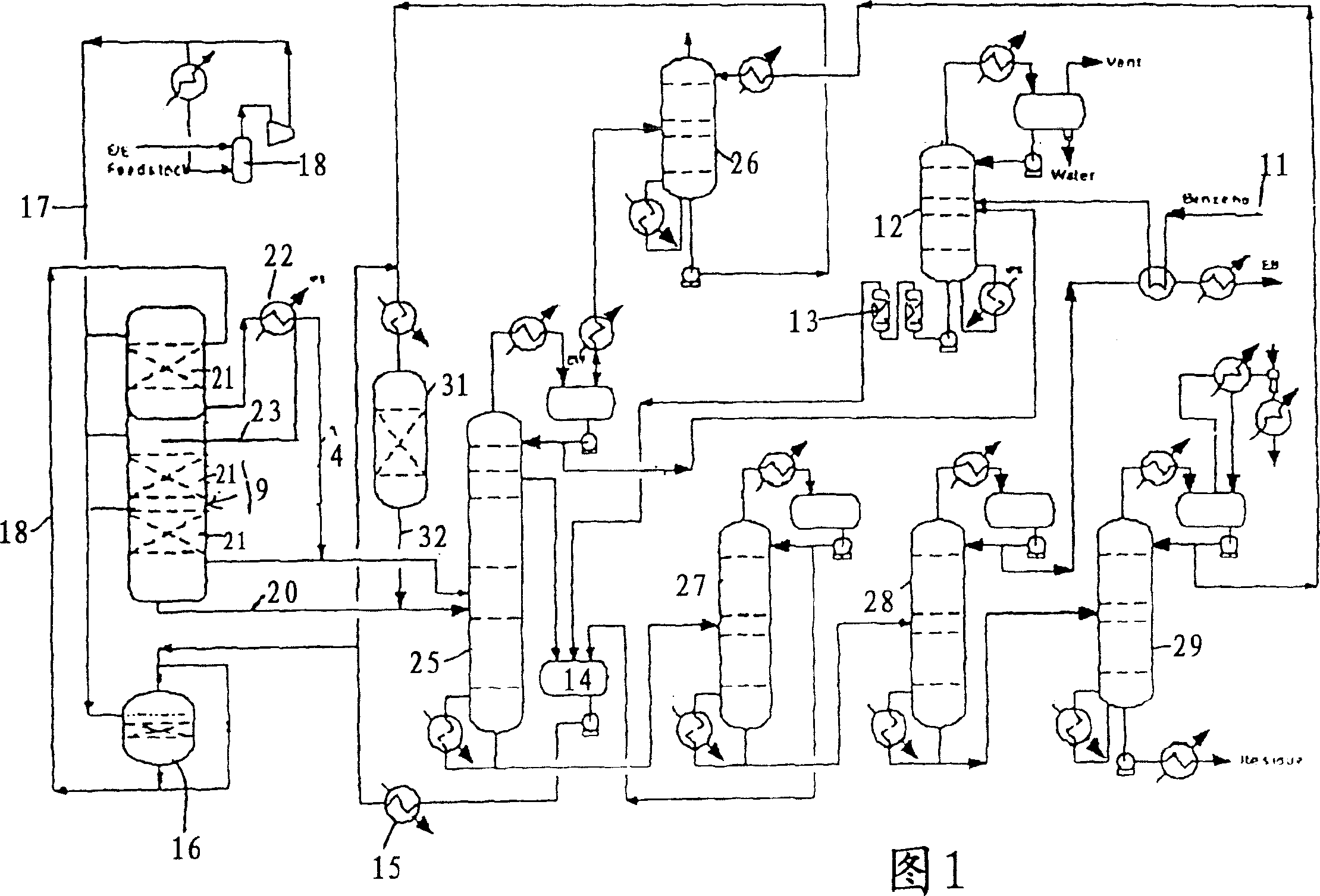

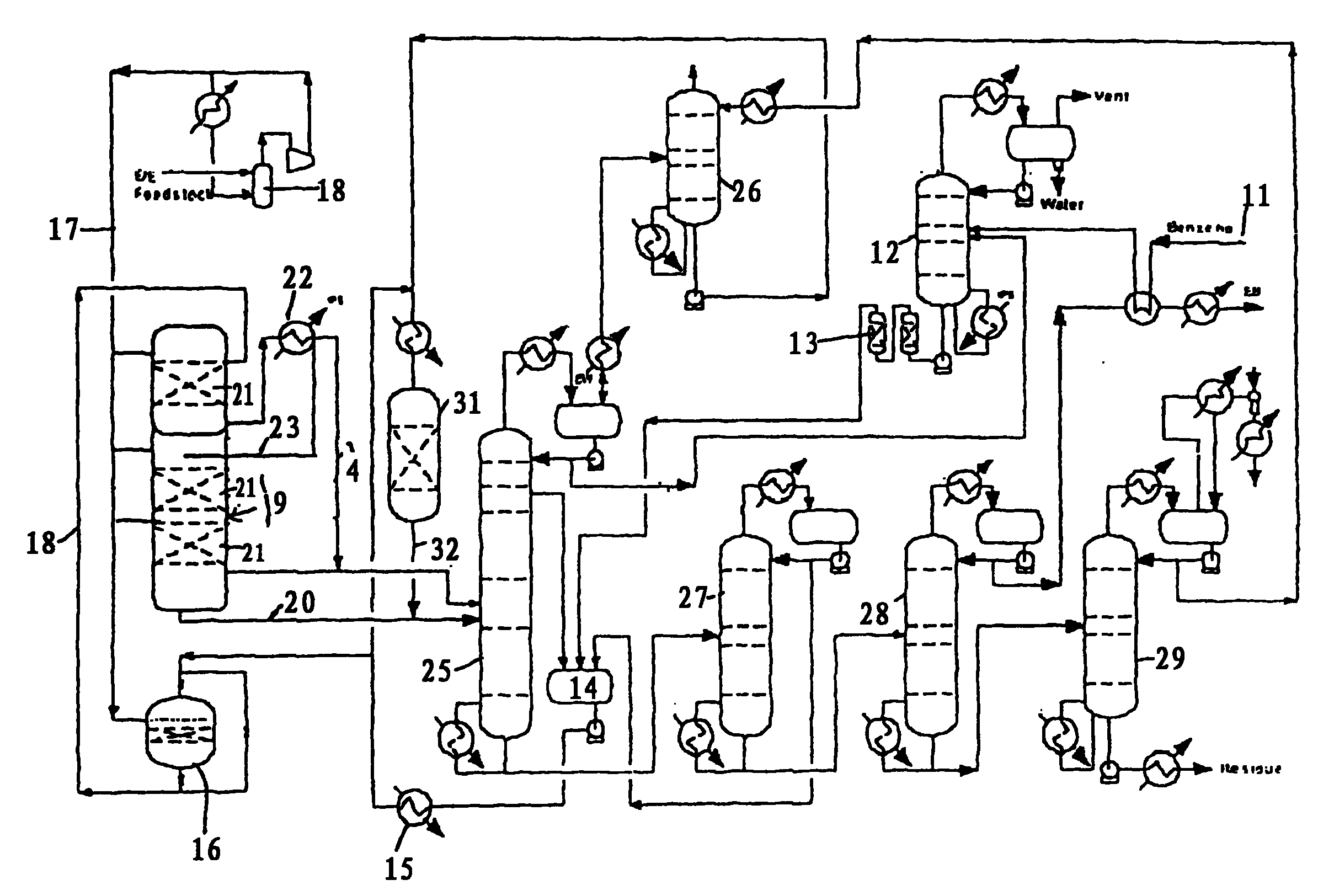

Alkylaromatics production

A technology of aromatic compounds and alkylation, applied in the direction of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., can solve the problems of catalyst deactivation, complex and expensive reactive distillation units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] The first and fourth beds of a four-bed ethylbenzene reactor were simulated in an adiabatic fixed bed laboratory flow reactor equipped with a suitable loading of 4 grams of zeolite catalyst to facilitate the alkylation of benzene with ethylene.

[0061] The first bed liquid feed was pure benzene, while the simulated fourth bed liquid feed had the following composition:

[0062] Benzene 77.80%

[0063] Ethylbenzene 20.86%

[0064] Diethylbenzene 1.18%

[0065] Triethylbenzene 0.04%

[0066] The simulated first bed gas feed is a mixture of ethylene and ethane in a molar ratio of 65:35. The simulated operation of the first bed was performed at a temperature of 200°C, a pressure of 350 psig (2514 kPa), a WHSV of 0.68 (ethylene basis) and an aromatics:ethylene ratio of 57:1 weight basis). The ethylene conversion was 98.0%.

[0067] In one simulation, without intermediate stage ethane removal, the simulated fourth bed gas feed was a 33:67 molar mixture of ethylene and et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com