Structure and method for preventing micro image processing aligning mistake

A process and lithography technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as misalignment, component pattern offset, etc., and achieve the effect of reducing stress and improving deposition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

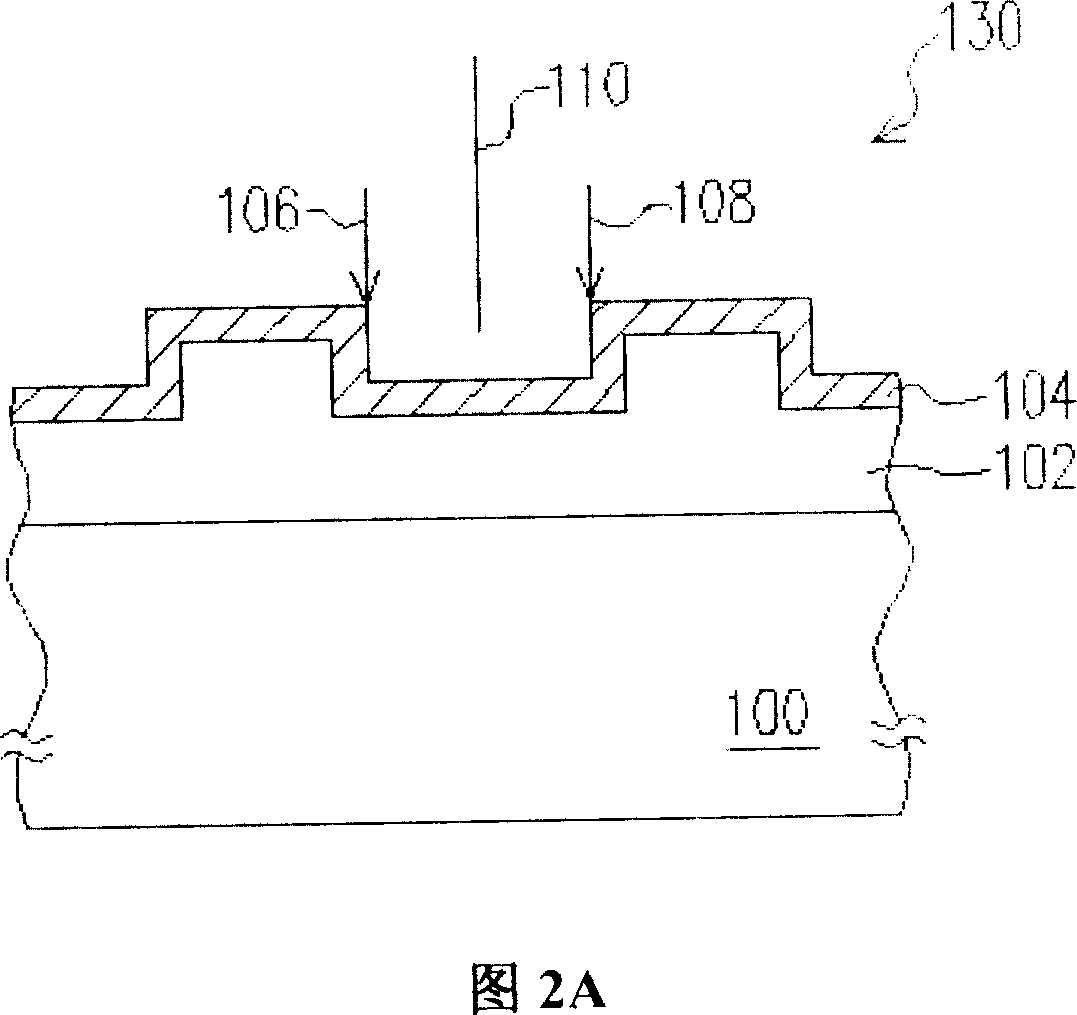

[0034] FIG. 3 is a schematic cross-sectional view of an alignment mark according to a preferred embodiment of the present invention, and FIG. 4 is an enlarged view at 300 in FIG. 3 . 3 and 4, an anti-electromigration layer 302 is formed on the structural layer 102 above the substrate 100, and then a conductive layer 104 is formed on the anti-electromigration layer 302, and a conductive layer 104 is formed on the conductive layer 104. anti-reflection layer 304 , so that the conductive layer 104 is sandwiched between the anti-electromigration layer 302 and the anti-reflection layer 304 . It is particularly worth mentioning that the anti-reflection layer 304 also has the functions of resisting electromigration and serving as the end point of the etching process.

[0035] In a preferred embodiment, the substrate 100 is, for example, a silicon substrate, and the structural layer 102 is, for example, a patterned dielectric layer. The conductive layer 104 is, for example, an aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com