Full-automatic accurate pressure testing control instrument

A precision pressure and control instrument technology, applied in the measurement of fluid pressure, instruments, measuring devices, etc., can solve the problems of huge procurement costs, only 0.05% or 0.02% of the full scale, and bulky, and achieves cost-effective, cost-effective, Good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

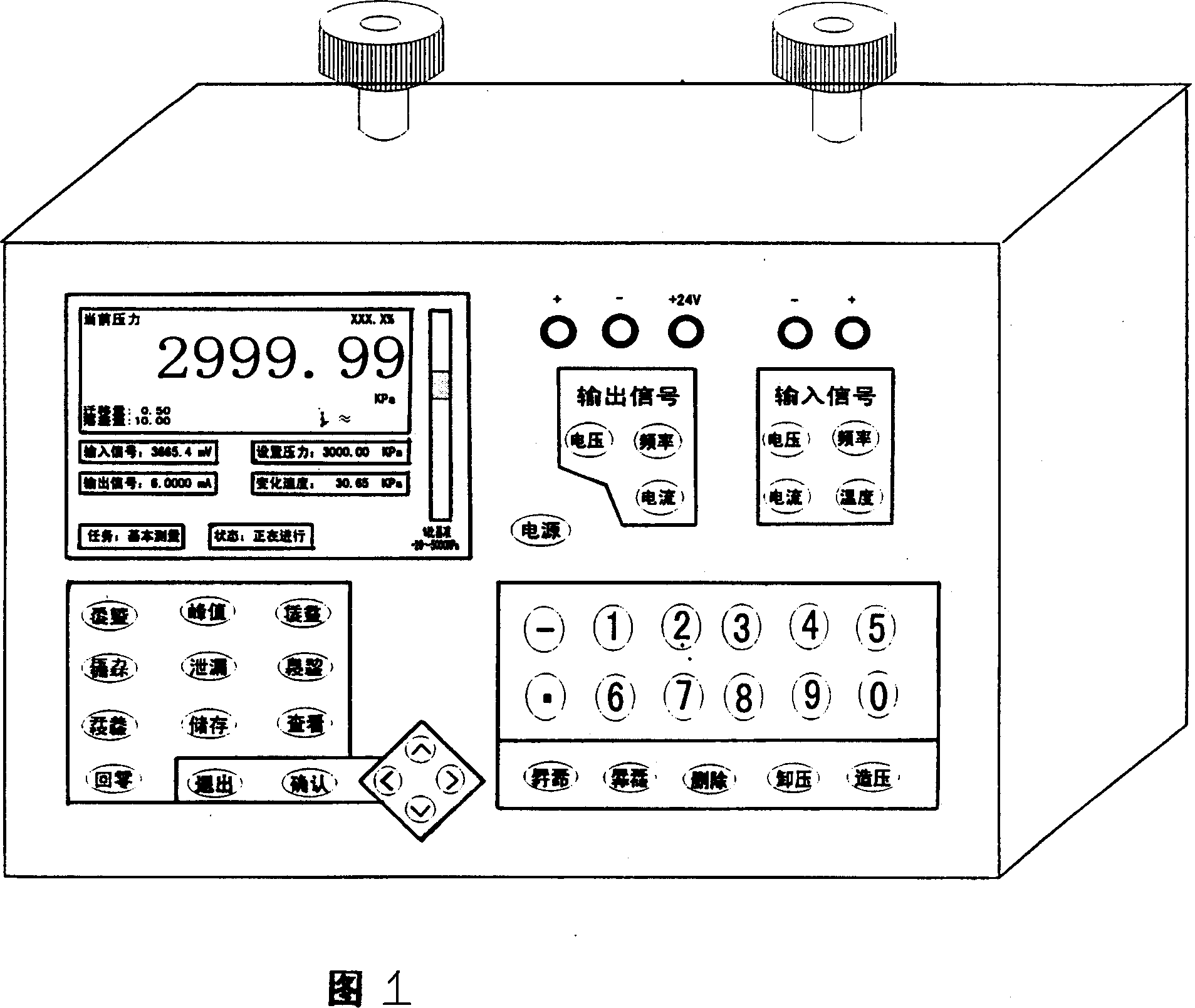

[0025] Referring to Fig. 1, the present invention is a kind of box-type instrument, and its measuring and control systems are installed inside the box body, the pressure input and output interface is installed on the top or the rear of the box body, other interfaces such as signal input and output interface, communication interface, The power interface is installed at the front or rear of the cabinet, and the location can also be changed according to different applications.

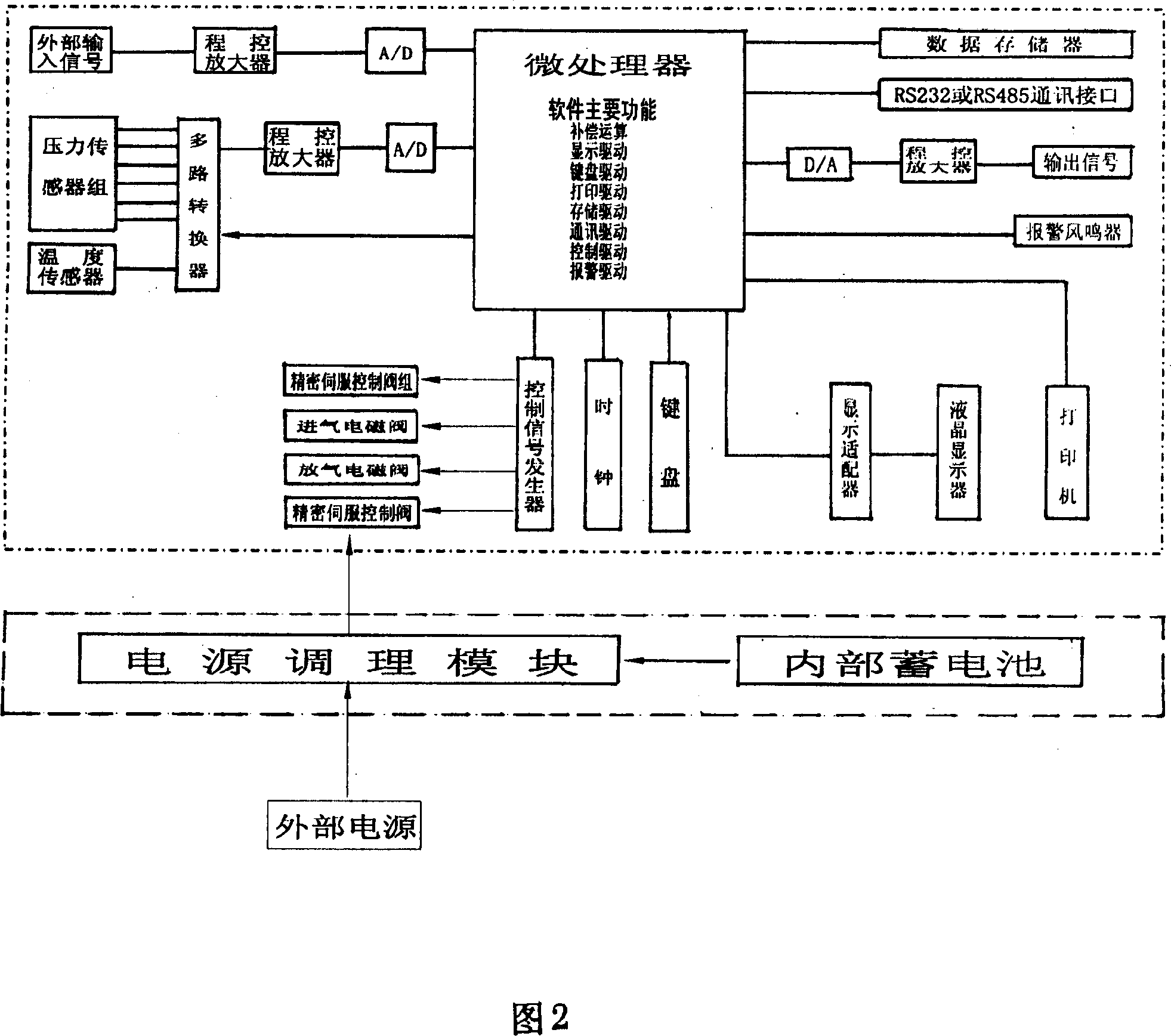

[0026] Referring to Fig. 2, the automatic precision pressure calibration controller includes a single-chip microcomputer, and the program on the single-chip microcomputer can realize linearity error correction and temperature error correction. The single-chip microcomputer is connected with the pressure sensor group of the measurement system through the A / D converter, the program-controlled amplifier and the multiplexer, and the single-chip microcomputer is connected with the temperature sensor through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com