Design and process method for profile and structure of streamline locomotive

A processing method and streamlined technology, applied to railway car body components, calculations, railway car bodies, etc., can solve the problems of long production cycle and high labor intensity, and achieve high work efficiency, simple process and saving internal space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing for further explanation:

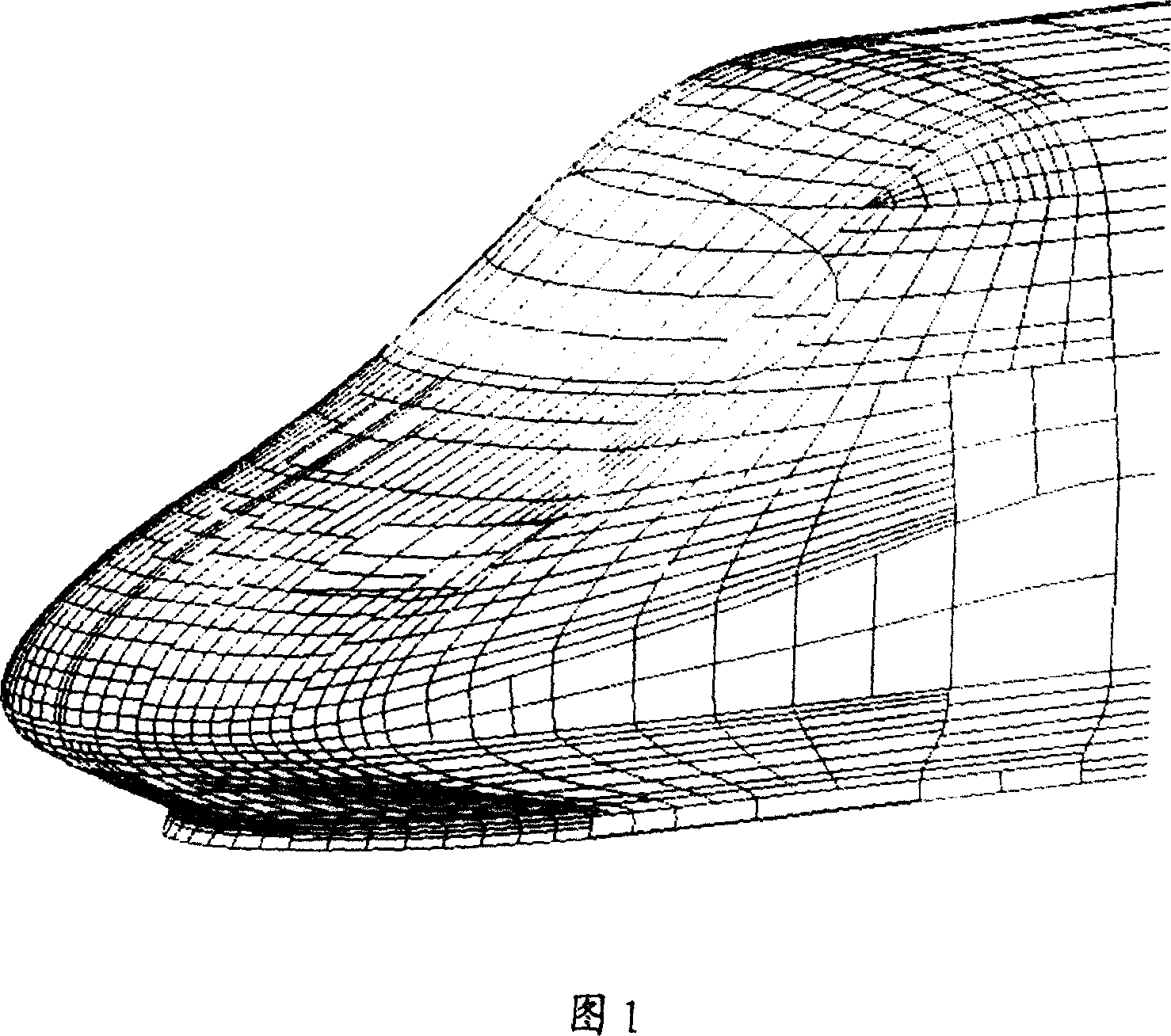

[0021] ①The shape design method of the streamlined train head is to synthesize the input control points into a non-uniform rational B-spline NURBS (Non Uniform Rational B-Spline Surface) curve to form the main shape line; Control the molded lines in the middle, and modify these molded lines dynamically in space to make them form a set of spatial network control molded lines; then disconnect these molded lines in space, and then connect them into three-dimensional shape surface patches; connect these surface pieces in space Tangentially, the desired shape surface is formed. The generated contour surface is tested by various surface smoothing methods such as surface illumination, contour lines, and isocurvature lines to obtain the final contour surface. The final shape data can be obtained by positioning the surface with points or lines.

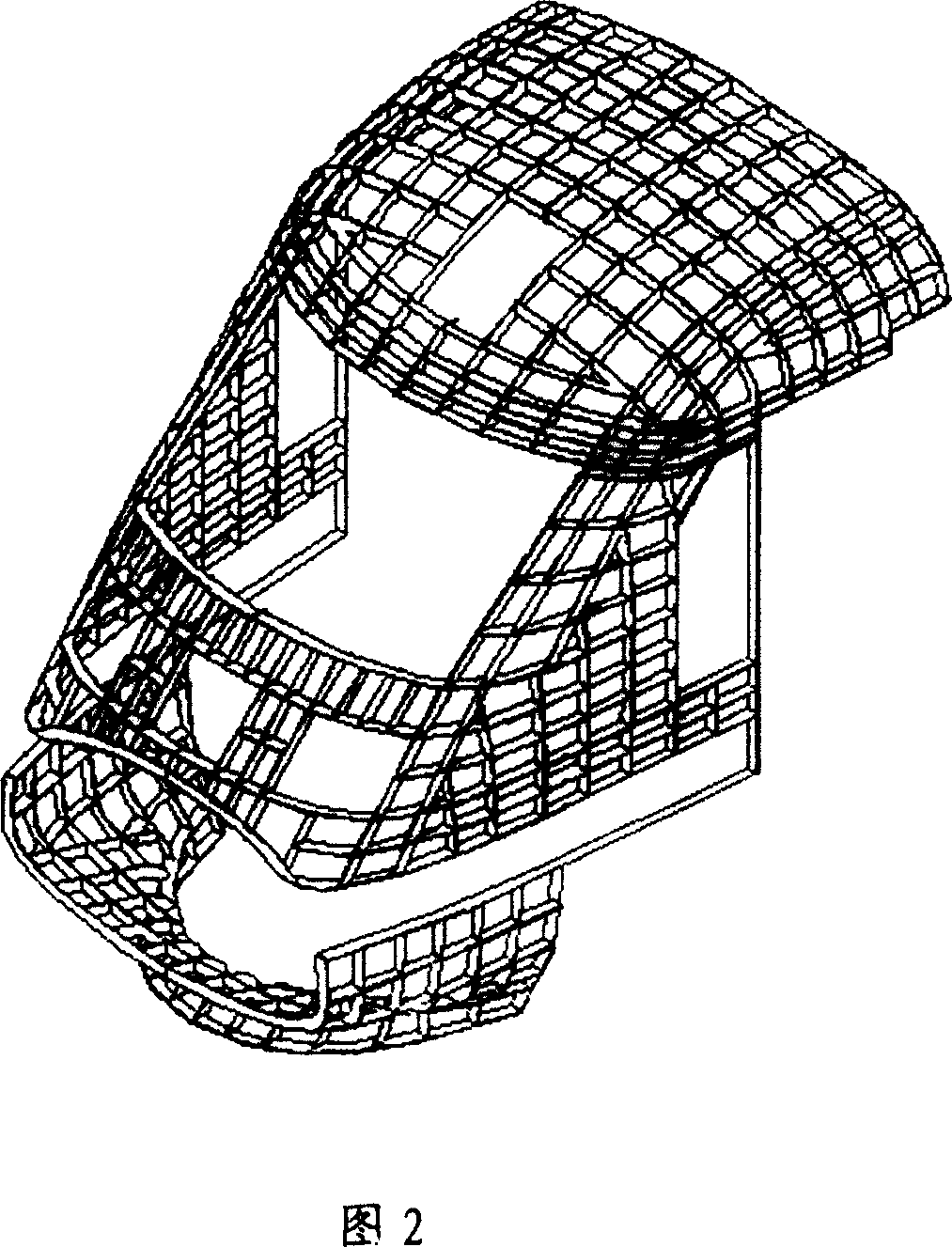

[0022] ②The structural design method of the head plate gir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com