Electromagnetic volume factor fluid engine

A power machine, volume technology, applied in the direction of machine/engine, liquid variable capacity machinery, mechanical equipment, etc., can solve problems such as many moving and transmission parts, complex mechanical structure, difficult maintenance, etc., to solve environmental protection and safety problems, expand Scope of application, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

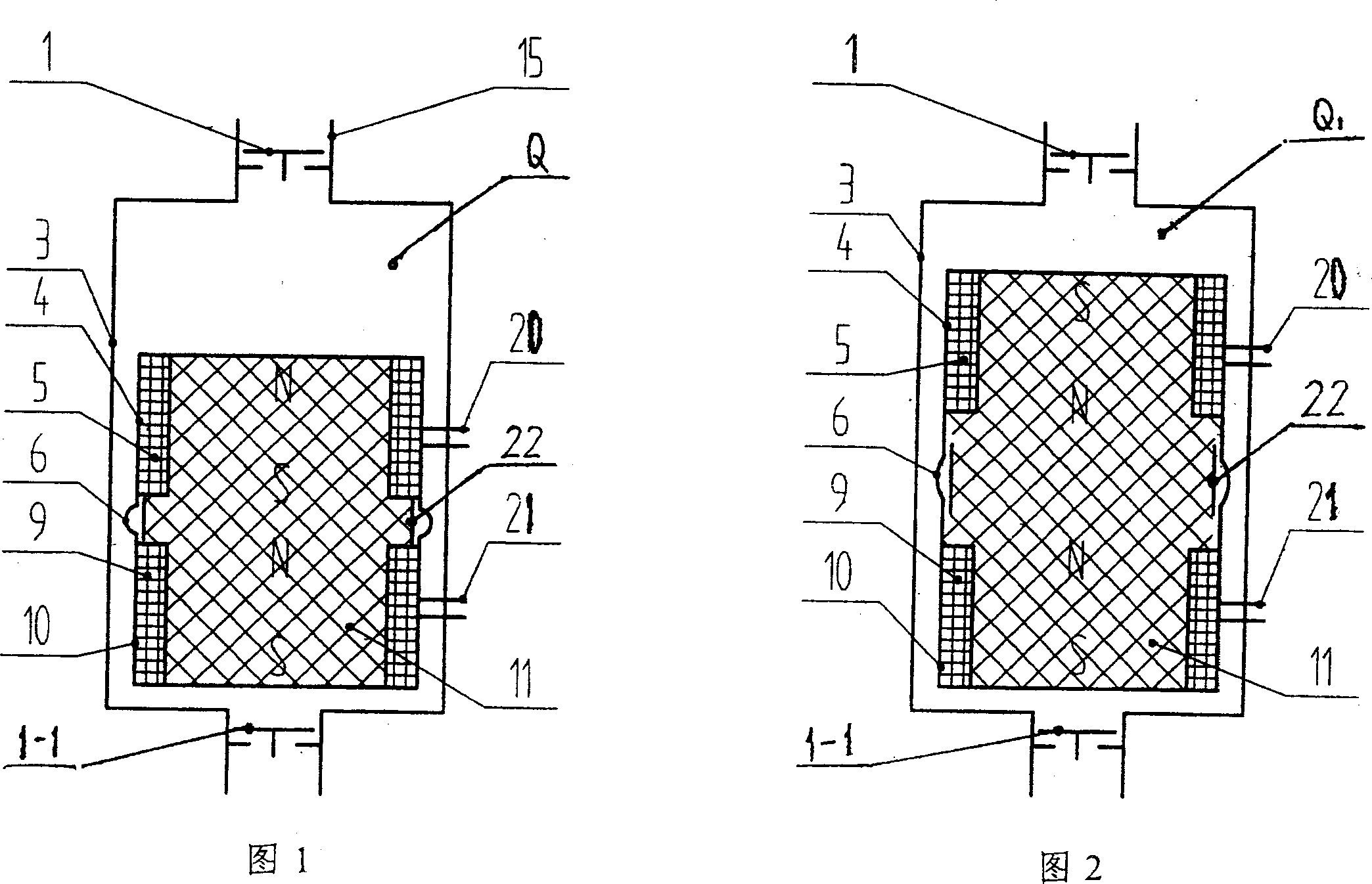

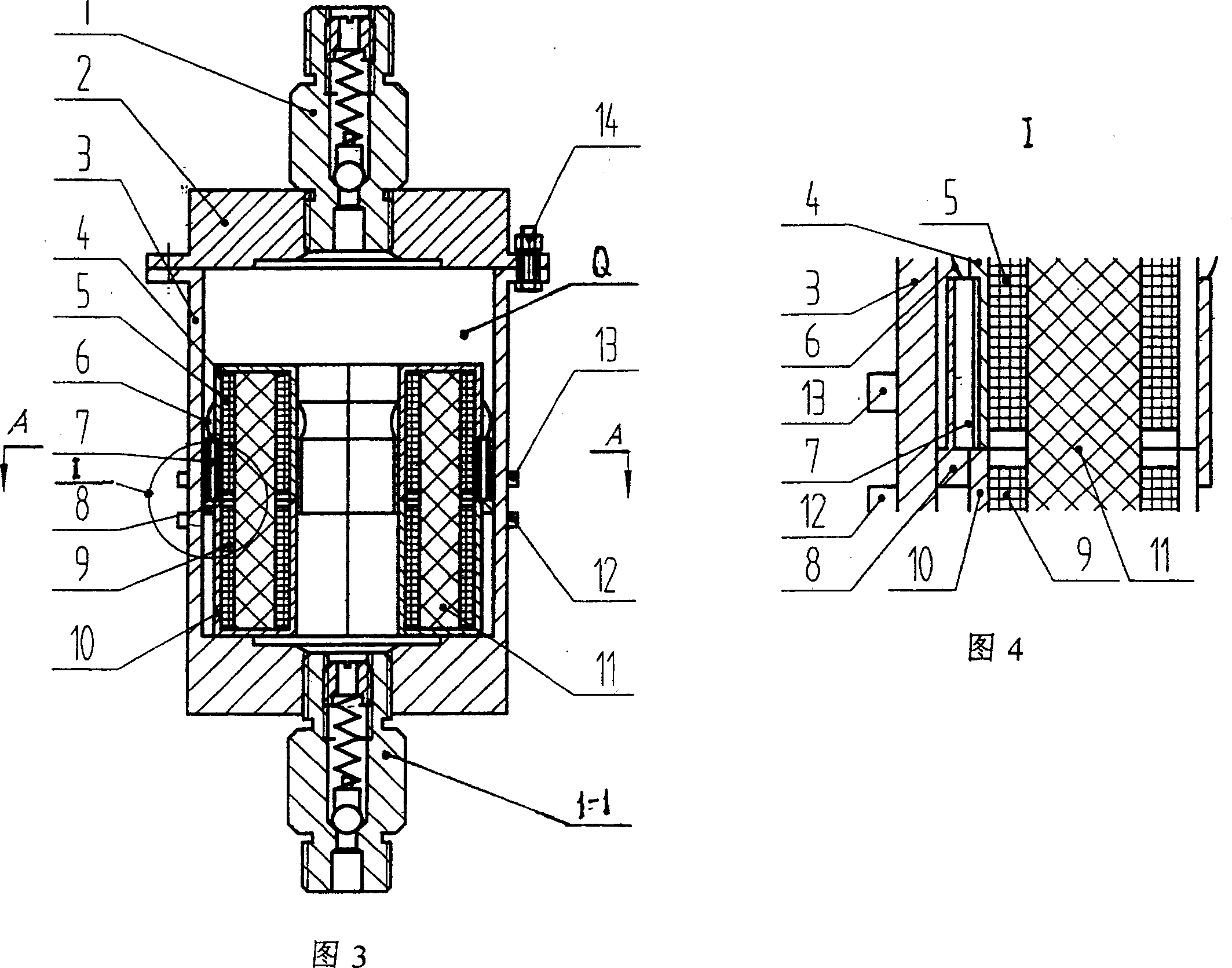

[0017] Embodiment 1, with reference to accompanying drawings 3, 4, 5, 6, the electromagnetic volume factor fluid power machine is made up of outlet check valve 1, inlet check valve 1-1, pump cover 2 and pump body 3, and its characteristic is that in the pump body 3. Six "electromagnetic volume factors" are evenly distributed in the sealed volume cavity; There is a movable magnet coil 5, a fixed magnet coil 9 is installed on the inner wall of the fixed magnet cover 10, a guide key 7 is arranged between the two magnet covers, and elastic medium 11 is filled in the sealed cavity of the two magnet covers; A coil wire 20 (see accompanying drawing 1) Connect the movable magnet coil 5 and the movable magnet coil connection ring 13, and the B coil wire 21 connects the fixed magnet coil 9 and the fixed magnet coil connection ring 12; the movable and fixed magnet sleeves 4 and 10 are made of magnetic materials, and the shape is a circular cup shape , the two are mouth to mouth, sealed a...

Embodiment 2

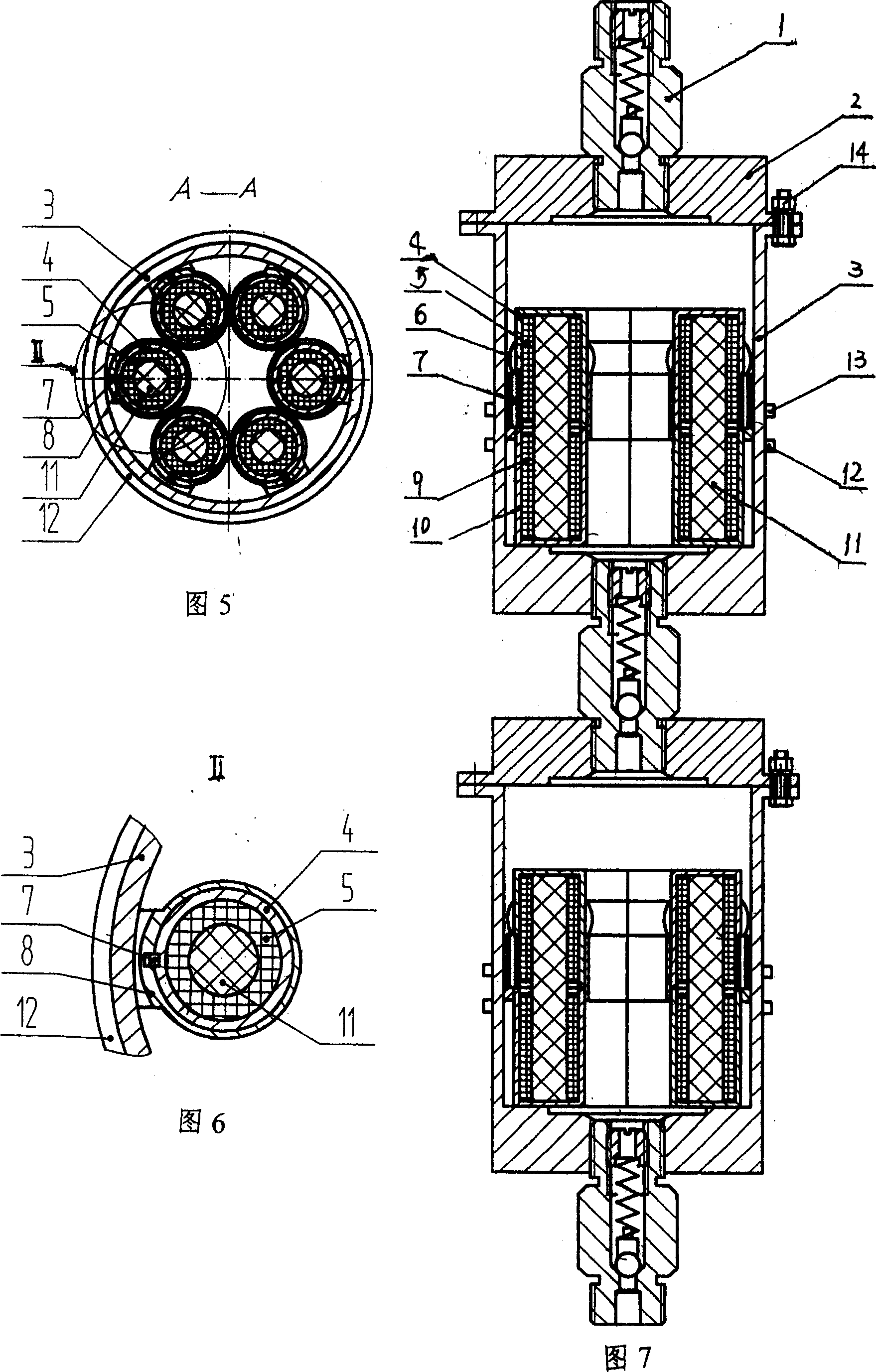

[0019] Embodiment 2, referring to accompanying drawing 7, has the same structure as Embodiment 1, except that two electromagnetic volume factor fluid dynamic machines are connected in series to increase the fluid output pressure.

Embodiment 3

[0020] Embodiment 3, referring to accompanying drawing 8, has the same structure as Embodiment 1, except that two electromagnetic volume factor fluid dynamic machines are connected in parallel. This parallel connection can improve the fluid mass effect caused by intermittent operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com