Pressure proof strontium titanate base energy storage medium ceramic and its preparation method

A technology of energy storage medium and titanic acid, which is applied in the field of pressure-resistant strontium titanate-based energy storage medium ceramics and preparation, can solve the problems that have not yet been seen, and achieve the effects of high dielectric constant, high breakdown strength and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

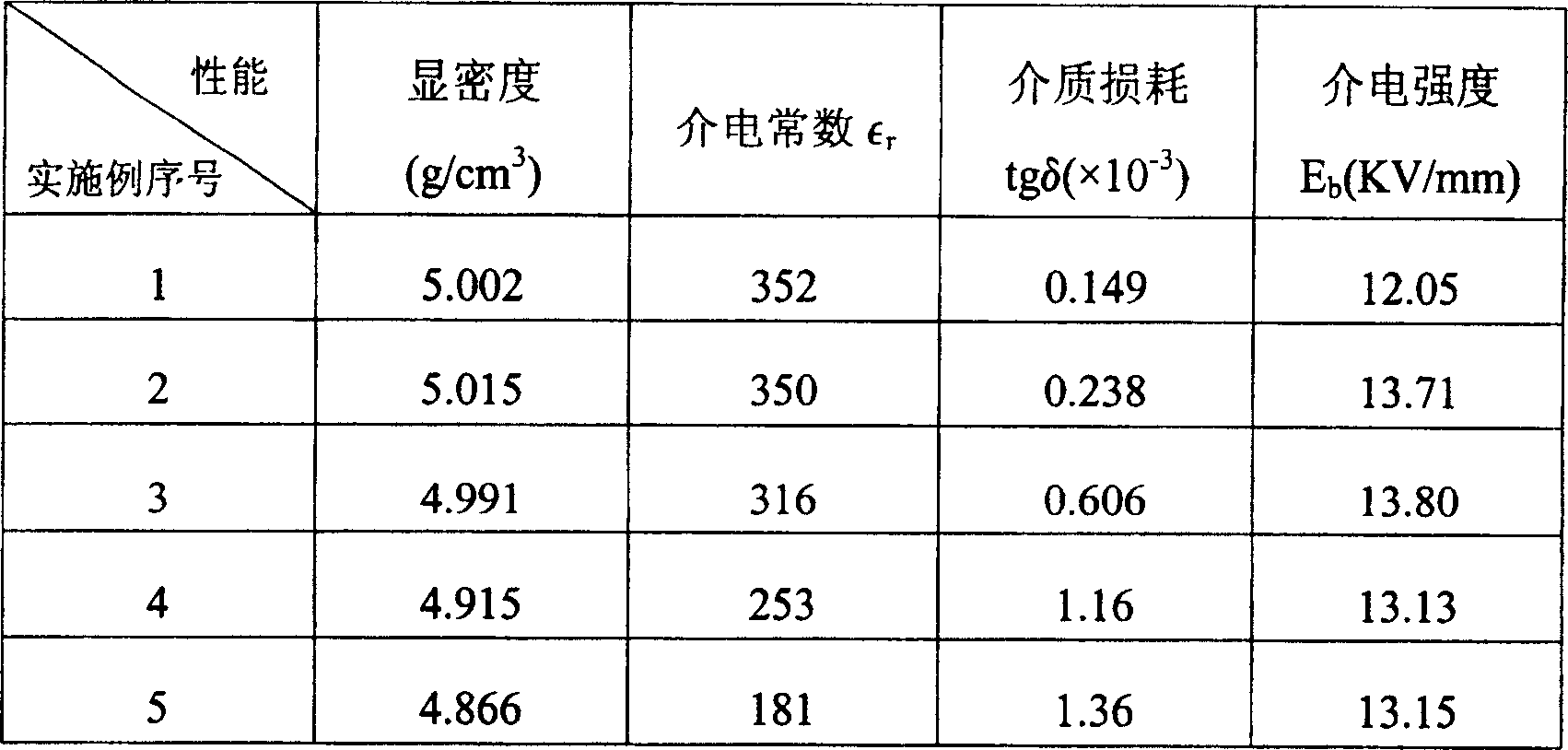

[0016] The formulas of Examples 1-5 are listed in Table 1, and the properties of each example sample are listed in Table 2.

[0017] Table 1

[0018] Table 2

[0019] Test conditions: The apparent density is measured by the Archimedes drainage method; the dielectric constant and dielectric loss are measured at a frequency of 1MHz; the dielectric strength is measured with insulating transformer oil as the medium. The test temperature is room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com