Integration of solvent deasphalting and gasification

A deasphalting and process technology, applied in the field of extraction and gasification of asphaltenes, can solve the problems of high cost of solvent recovery, low selectivity, inability to extract aromatic compounds and resins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

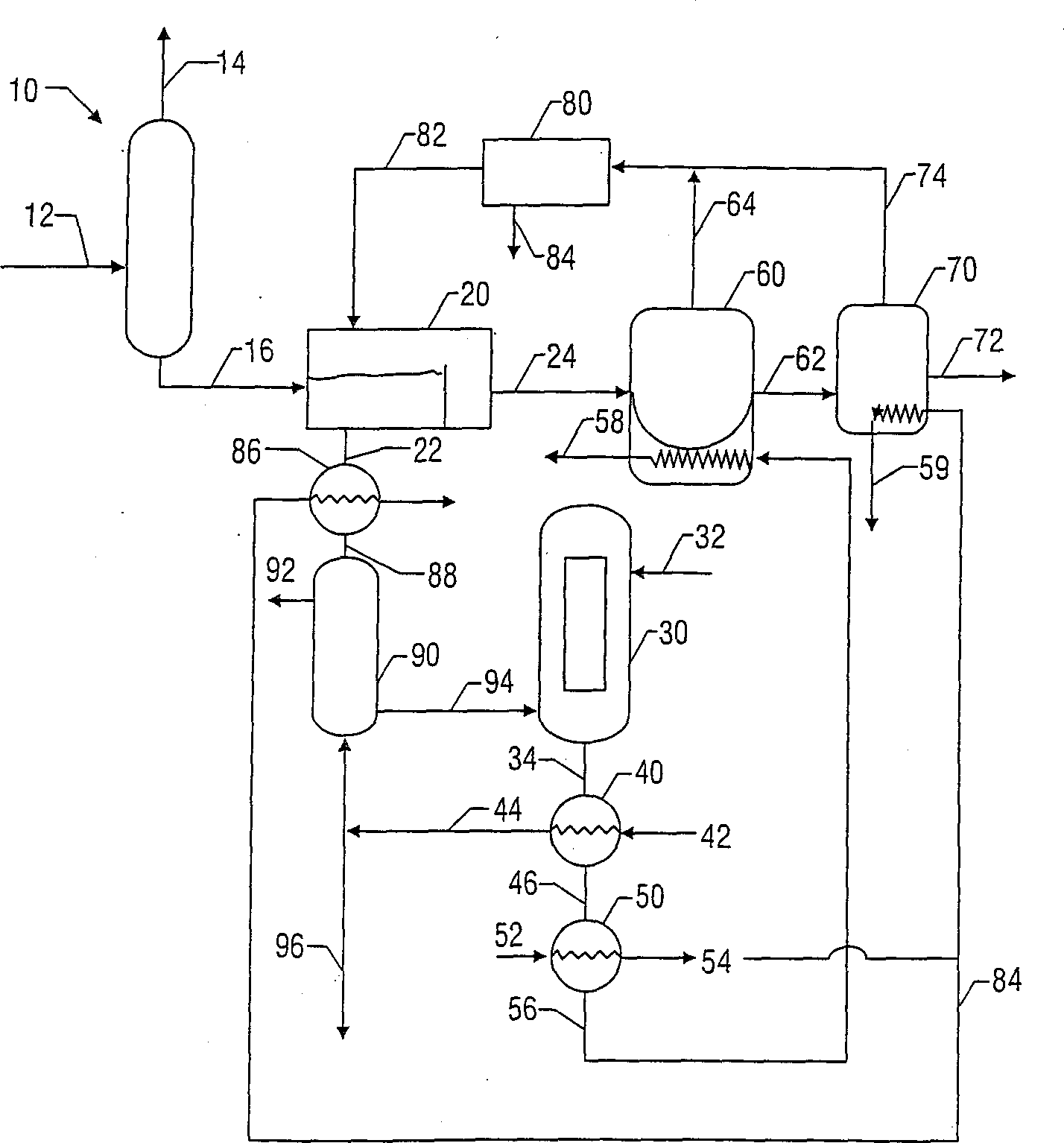

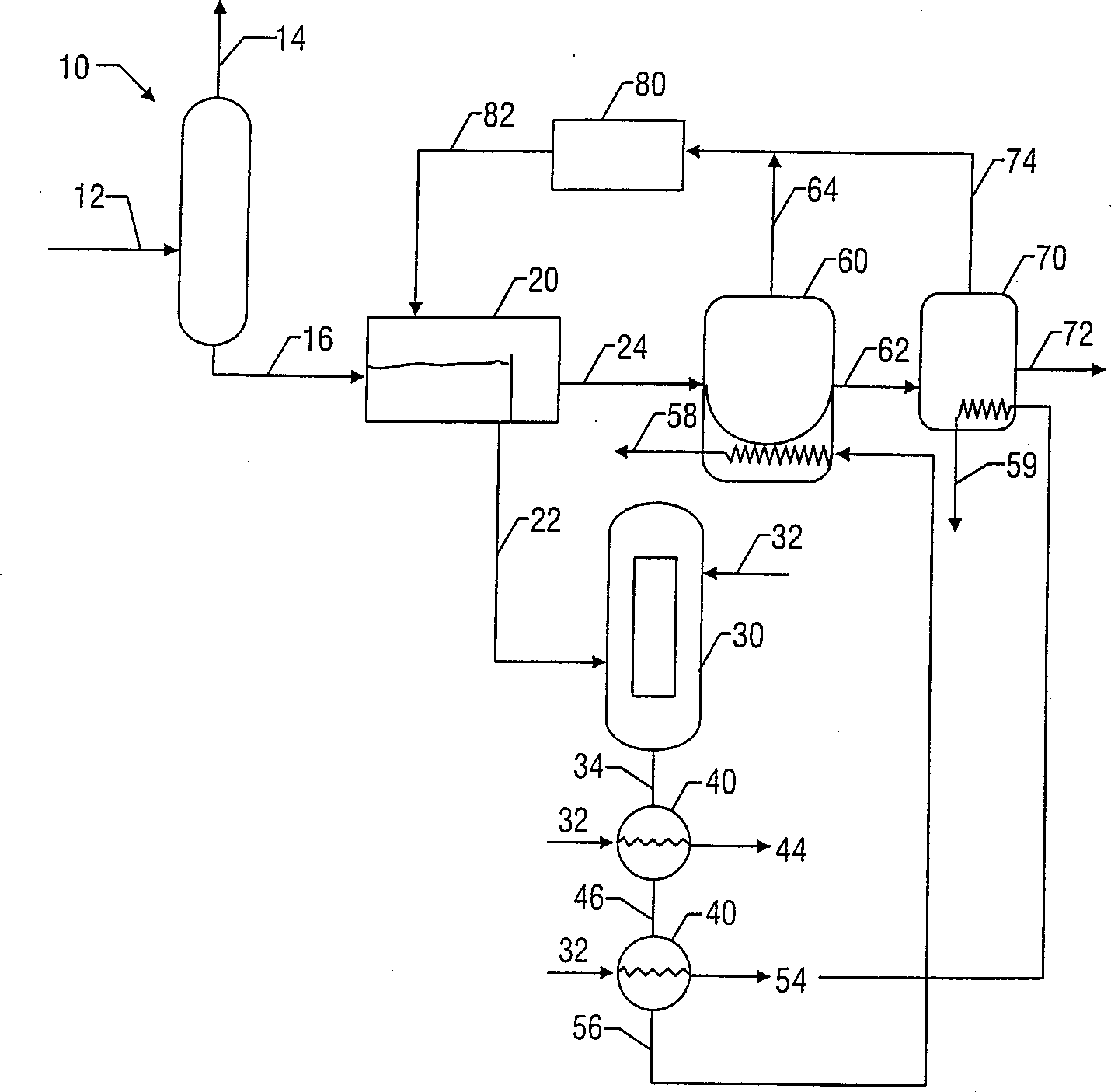

[0010] In the context of this application, the term "precipitation" as used in precipitating asphaltenes refers to the formation of asphaltene-rich material into a second phase, which may be and preferably is a fluid or fluid-like phase. In a preferred embodiment of the invention, the precipitated asphaltene-rich material is pumped to a gasifier. A solid asphaltene-rich phase is not preferred due to handling issues.

[0011] The term "gasification zone" as used in this application refers to the zone of a reactor where incoming hydrocarbon material, especially asphaltene-rich material, is mixed with oxygen-containing gas and partially combusted.

[0012] As used in this application, the terms "deasphalted hydrocarbons", "deasphalted oil", DAO and "paraffinic oil" are used interchangeably and refer to the Oil in asphalt solvent.

[0013] The invention is a combined process of extracting asphaltenes with a solvent and gasification through partial oxidation, which utilizes the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com