Vaporization equipment for material sublimation

A technology of evaporation device and heating device, which is used in devices for measuring time interval, vacuum evaporation coating, metal material coating process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

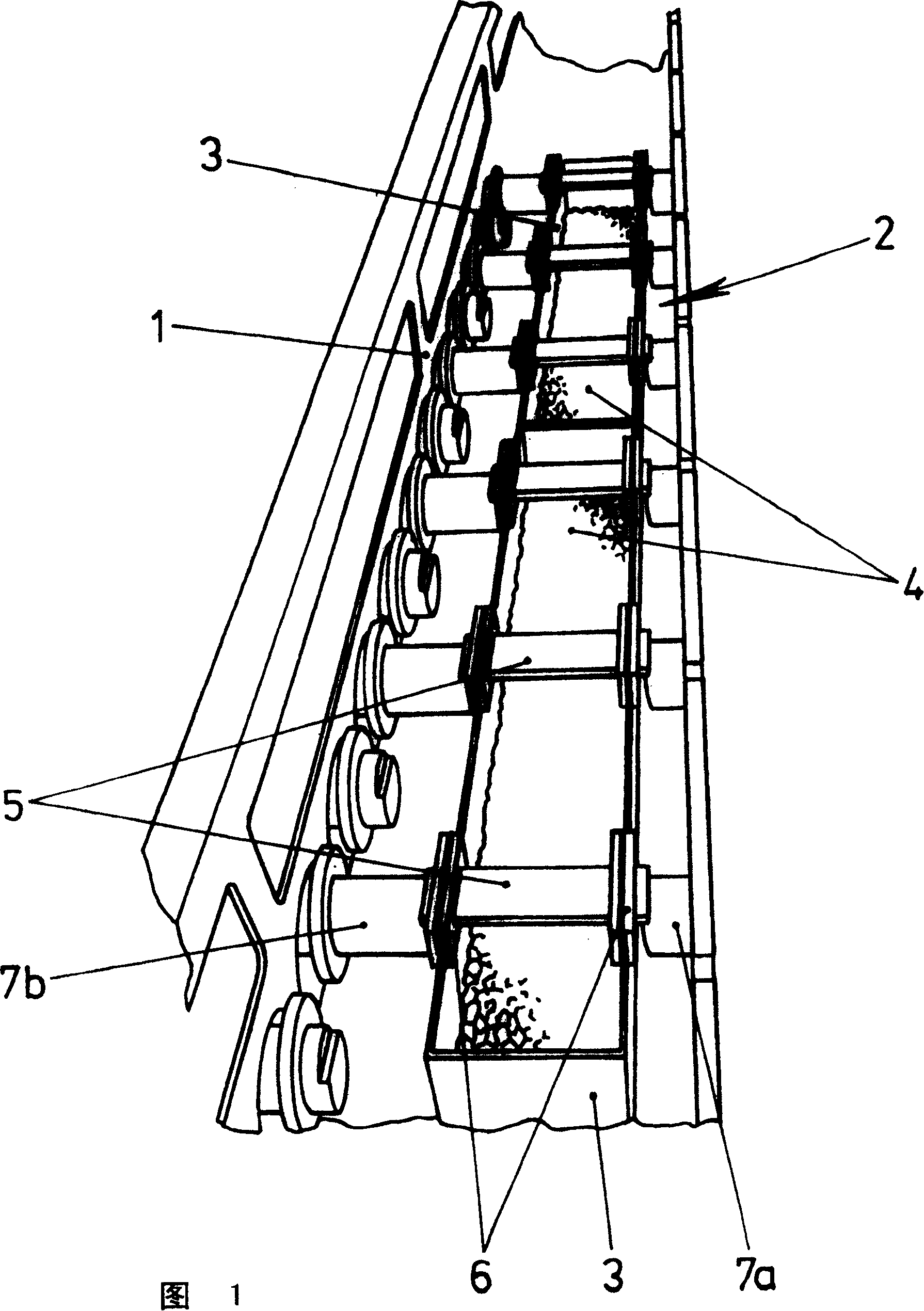

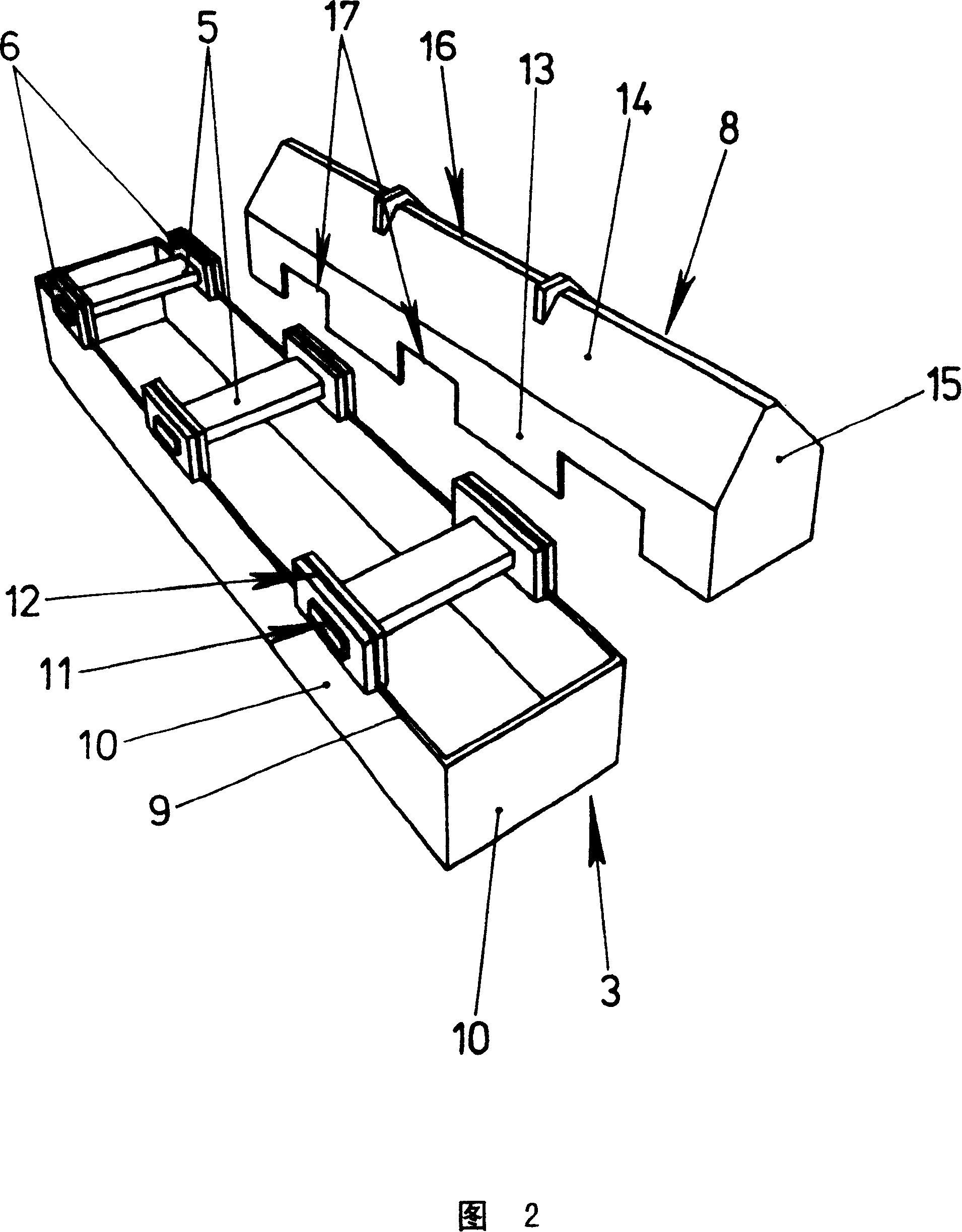

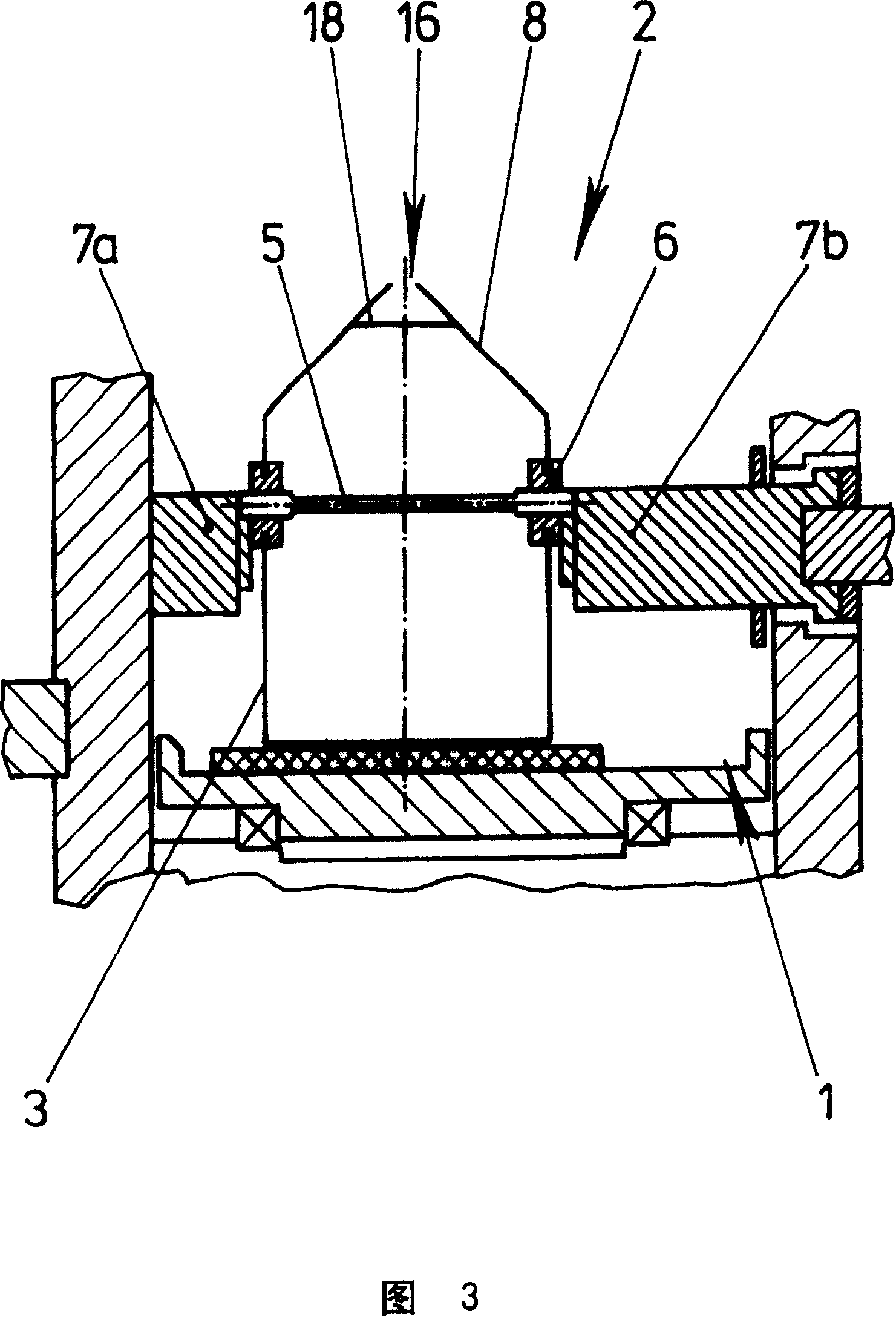

[0018] See Figure 1 first. One can see the vapor deposition chambers 1 of a coating plant, which are distributed in the form of wells over the width of the plant. By means of rollers, not shown, the film web to be coated can be passed through the vapor deposition chamber opening. In the evaporation chamber 1 there is an evaporation device 2, which consists of two elongated grooves 3, the short sides of which are in contact with each other. In the tank 3 there is material 4 to be evaporated, in this case zinc sulphide granules, which are introduced into the tank as bulk material. Three heating rods 5 are arranged on each slot 3 and are arranged at equal distances from one another. They are fixed by the support ring 6, wherein the two ends of the heating rod 5 protrude out of the groove 3 and can be connected with the contact rod 7 protruding from the wall of the evaporation chamber. The slot 3 is closed by means of a cover, which is not shown in this figure but is shown in d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com