Composition for livestock food and production thereof

A technology of feed composition and production method, which is applied in animal feed, animal feed, animal husbandry, etc., and can solve problems such as livestock death, high phosphorus content in wheat bran, and livestock suffering from ureterolithiasis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A production method of fermented wheat bran will be provided below as a typical example of the basic feed composition that can be used in the present invention.

[0041] (1) Add 50 kg of swill to 100 kg of wheat bran, and adjust the water content to 35%.

[0042] (2) The resulting mixture was sterilized with 100°C steam for 30 minutes.

[0043] (3) After cooling to 40 degrees, spray 100 grams of Aspergillus on it.

[0044] (4) The resulting mixture was further air-cooled to 35°C.

[0045] (5) Six hours after the spraying of Aspergillus, the activity of Aspergillus produced heat, and the temperature of the product gradually increased.

[0046] (6) After that, air cool the product to keep its temperature within 35-50 degrees.

[0047] (7) 60 hours after the addition of Aspergillus, the water content reached about 20%.

[0048] (8) Add 20 kg of swill, mix the resulting mixture, and adjust its water content to about 30%.

[0049] (9) Aspergillus becomes active again an...

Embodiment 2

[0052] In addition, to compare the components of wheat bran with Aspergillus-treated (fermented) wheat bran, Aspergillus was used to produce fermented wheat bran whose composition was compared with that of normal untreated wheat bran.

[0053] Table 1

[0054] Comparative Analysis of Wheat Bran and Fermented Wheat Bran

[0055] usual wheat bran

[0056] Wheat Bran vs. Fermented Wheat Bran Contents

[0057] usual wheat bran

[0058] As shown above, the fermented bran was not significantly different from the untreated bran, except for about a 2% increase in protein content. As for amino acids, fermented wheat bran has more glutamic acid, and unprocessed wheat bran actually has higher levels of amino acids. In terms of vitamins, fermented wheat bran contains vitamin B 2 Just twice that of wheat bran.

Embodiment 3

[0060] To measure the effectiveness of a livestock feed composition containing fermented wheat bran as described above, 1,100 cows were fed energy feeds such as corn, soybeans, barley, hay, molasses, sugar beet pulp, etc. with a total of 30% by weight of fermented wheat bran Bran mixture.

[0061] As a result, the following notable effects were obtained:

[0062] (1) Fecal odor is reduced;

[0063] (2) The number of diarrheal cattle in a year is zero;

[0064] (3) diarrhea does not occur during the most important growth stage of a newborn calf growing into a cow after eating this feed composition; and

[0065] (4) The time to delivery to the market is shortened by 2-4 months.

[0066] That is, although no significant difference in composition between wheat bran and fermented wheat bran was seen in the component analysis, by adding fermented wheat bran to the feed composition, significantly different effects on livestock were obtained.

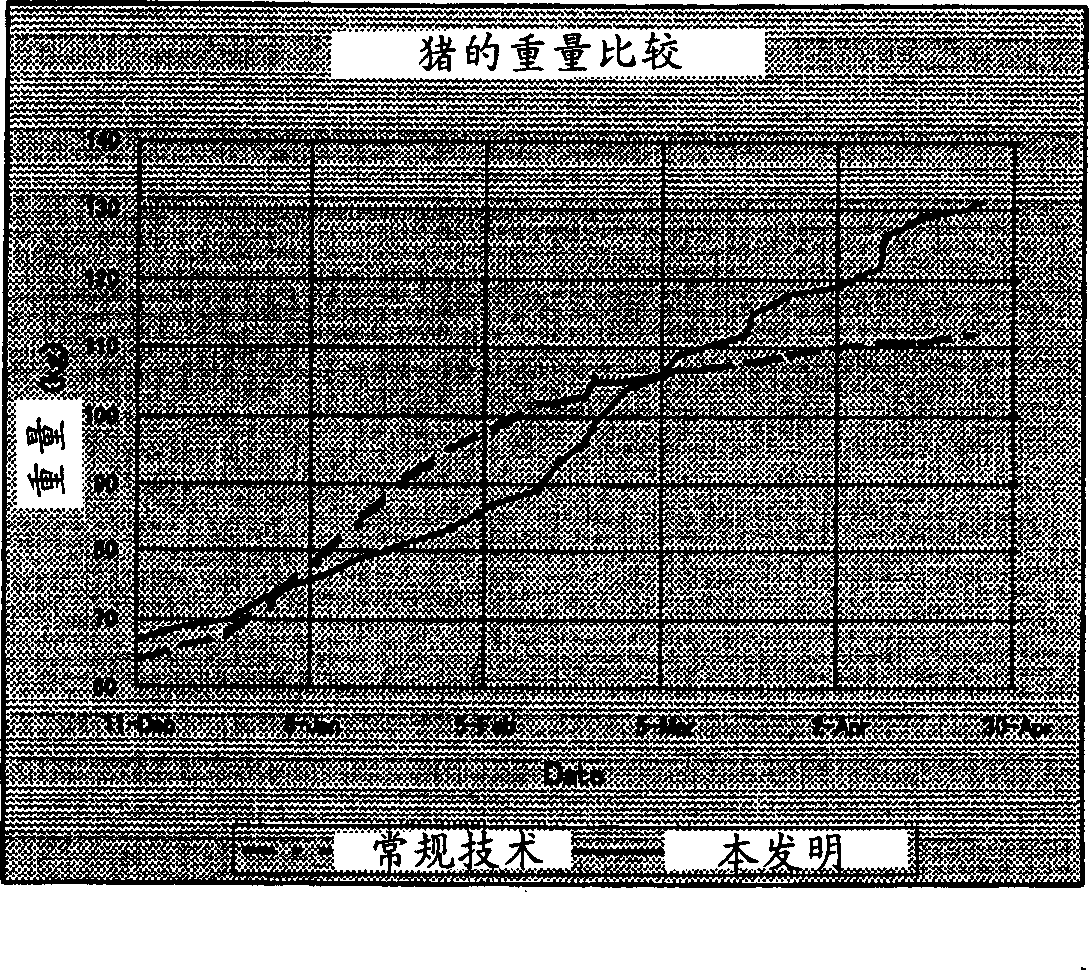

[0067] In addition, from 12 months a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com