Computerized digital control system of laser metal surface enhanced processor

A metal surface strengthening, numerical control system technology, applied in computer control, general control system, control/adjustment system, etc., can solve the problems of lack of support means for laser strengthening treatment, poor operation and maintenance performance, complicated and cumbersome control circuit connection, etc. , to achieve the effect of friendly operation interface, improve production efficiency and processing quality, easy to drive and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

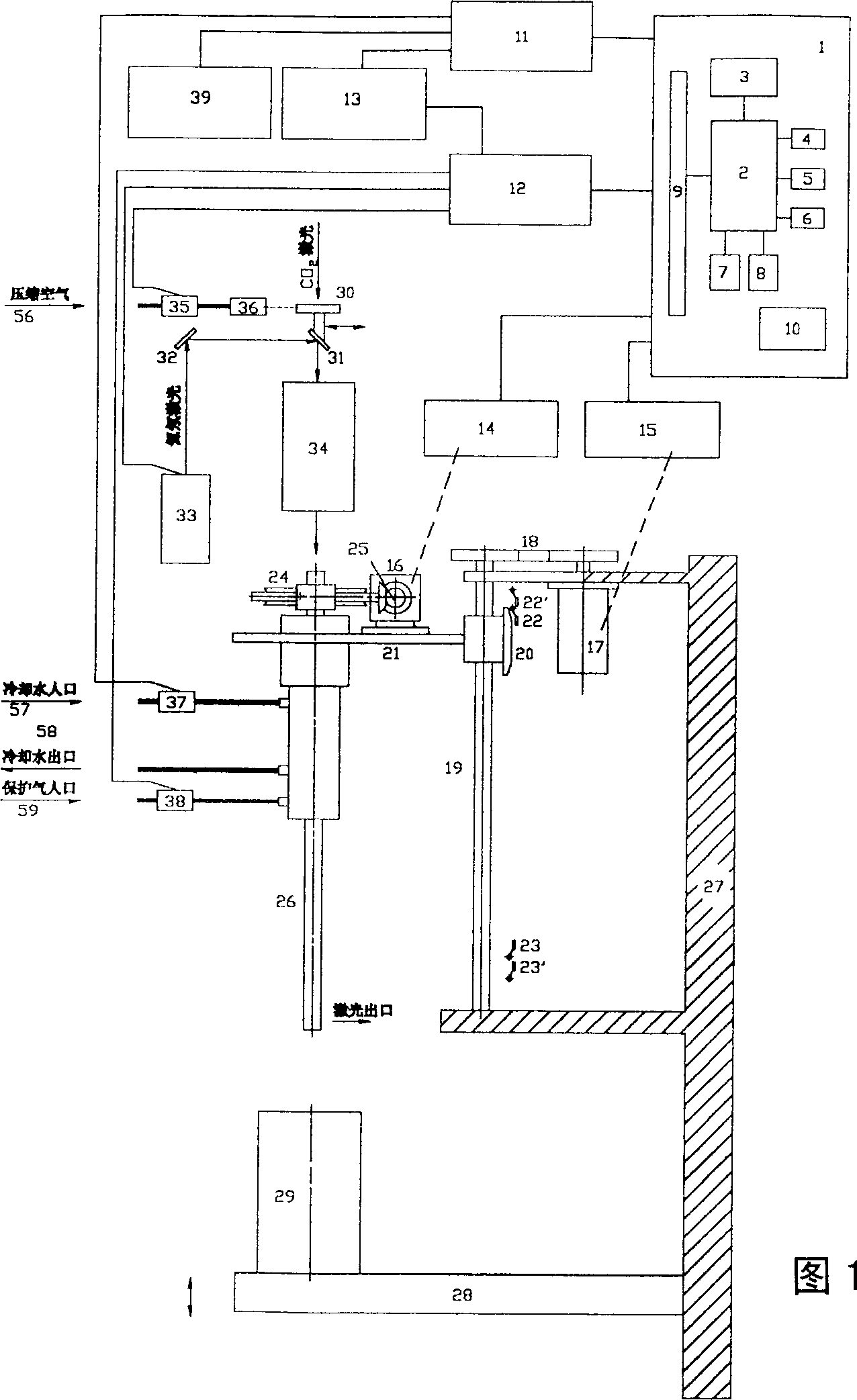

[0050] Fig. 1 is a schematic diagram of the system structure of the present invention.

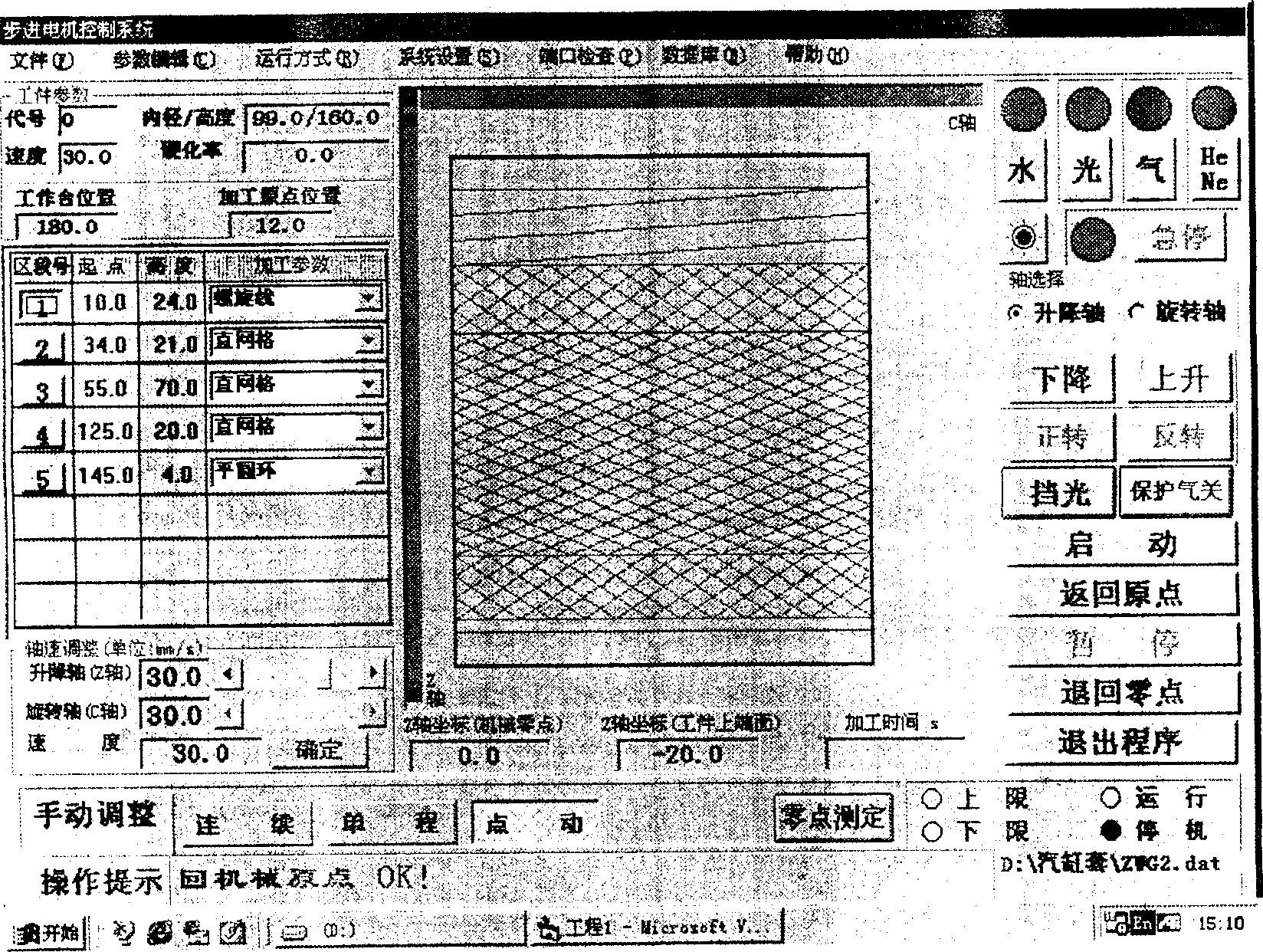

[0051]The Z-axis stepping motor 17 installed on the bed of the machine tool drives the lifting platform 21 to move up and down through the transmission gear 18 and the transmission screw 19. The lifting platform is equipped with a C-axis stepping motor 16, a main shaft part 26 and a main shaft transmission part... ...A pair of bevel gears 25 and a pair of worm gears 24, the motor 16 drives the main shaft 26 to rotate through the bevel gears 25 and the worm gears 24. The control program puts forward the walking control requirements to the stepping motion control card (hereinafter referred to as the stepping card) 9 in the form of walking commands, and the stepping card 9 sends out the stepping pulse signal PCW respectively as required C 、DCCW C and PCW Z 、DCCW Z to the stepper motor drivers 14 and 15, the drivers then generate the three-phase drive pulse signals required by the three-pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com