Method for machining cellular flexible structure material

A technology of flexible structure and processing method, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of high labor intensity of workers, affecting processing accuracy, low work efficiency, etc., to improve work efficiency and reduce labor. Strength, simple equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

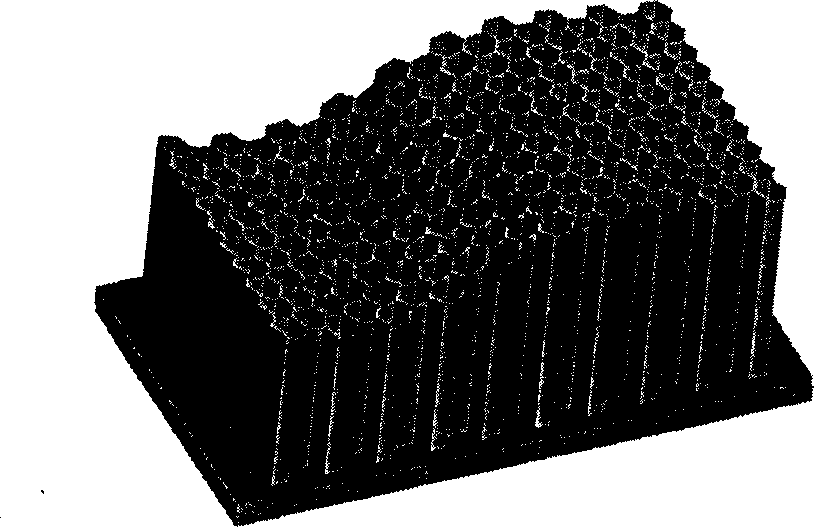

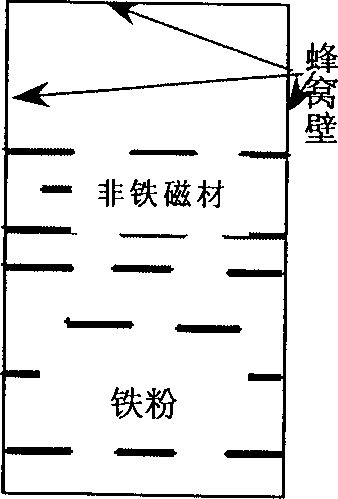

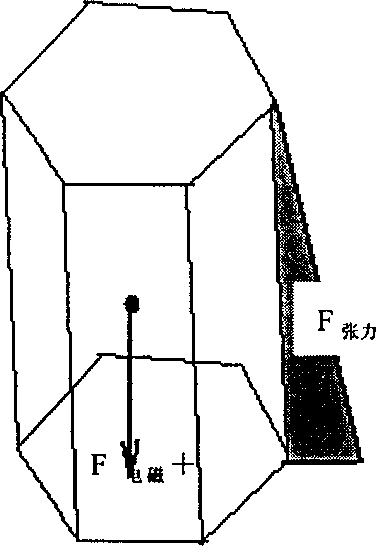

[0011] Newly design (or use existing) a clamping platform (ferromagnetic material), set induction coils on the clamping platform, generate a magnetic field parallel to the fiber direction during work, magnetize the iron powder, and make the iron powder generate downward pressing force (able to control). The honeycomb is placed on the platform according to the clamping requirements, and then an appropriate amount of iron powder is evenly poured into the honeycomb. The maximum height of the magnetic material is smaller than the lowest processing surface of the workpiece, and then a layer of aluminum powder is poured on the iron powder. Through several times of alternating magnetic field, the effect of compaction is produced on the iron powder. Then pour a layer of material that can effectively isolate the magnetic field on the iron powder. At this time, the stress state of the iron powder in the honeycomb is shown in Figure (3). Under the action of a strong magnetic field forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com