Continuous filament-yarn opening method and apparatus thereof

A filament and tow technology, which is applied in the field of continuous filament opening and fiber opening devices, can solve the problems of continuous filament disorder, difficult procedures, and difficulty in opening fiber uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

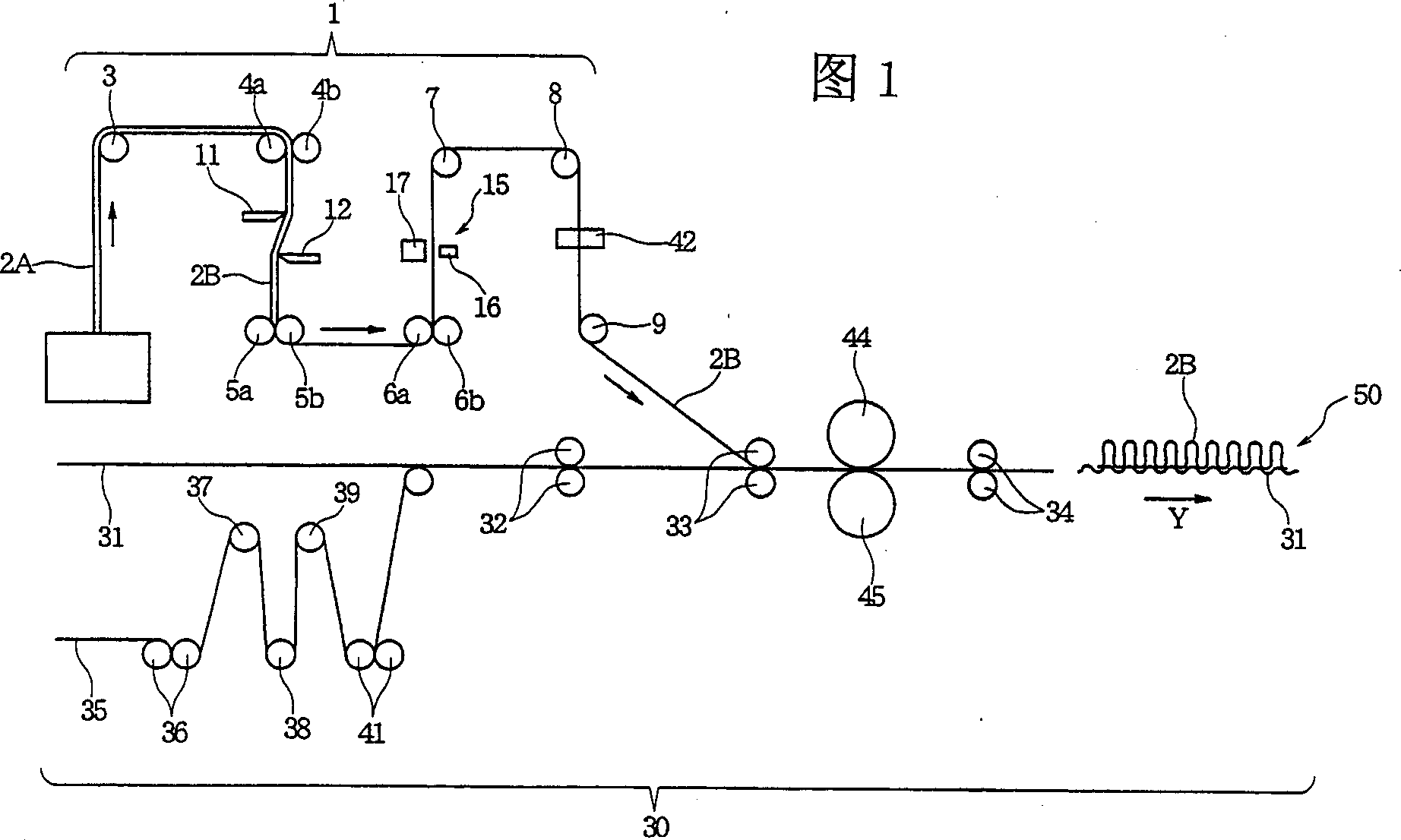

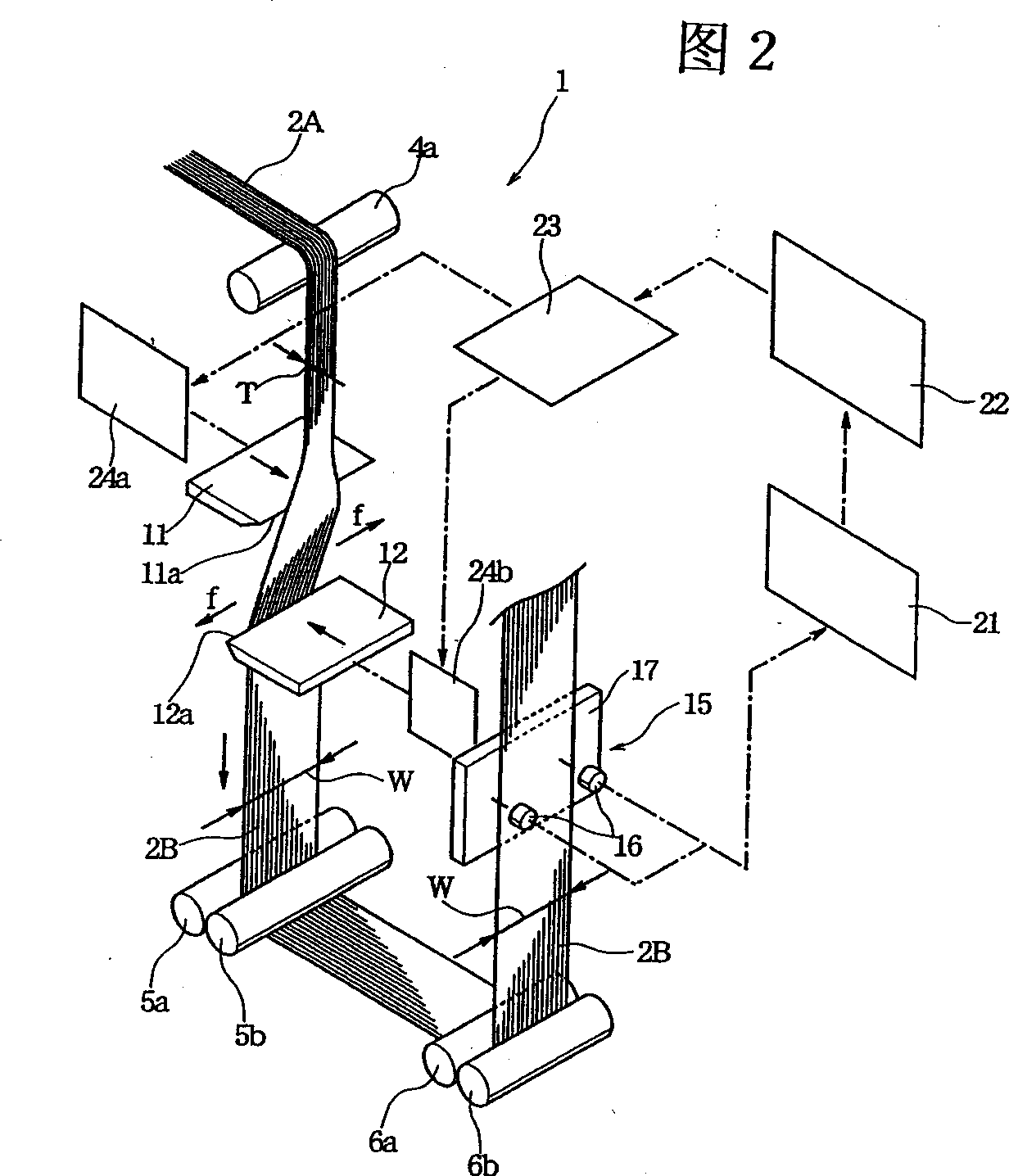

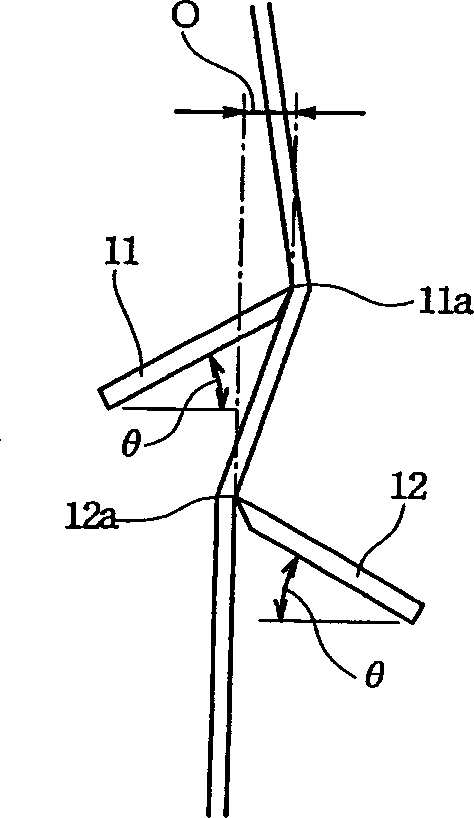

[0029] Fig. 1 is an explanatory view showing the method and apparatus for opening a tow of the present invention, and the method and apparatus for manufacturing a surface layer of an absorbent article using an open continuous filament; Partially enlarged perspective view of the fiber opening method and fiber opening device.

[0030] In the continuous filament opening step 1 shown in FIGS. 1 and 2 , a tow (TOW) 2A of bundled and crimped continuous filaments is supplied, and the tow is uniformly opened in the width direction.

[0031] The continuous filaments constituting the tow 2A are composite synthetic fibers with a core-sheath structure such as PE / PET and PE / PP, side-by-side composite fibers such as PE / PET and PE / PP, or single fibers such as PE, PP and PET.

[0032] The crimp is obtained by crimping (crimper-) during filament production, and then used after preheating calendering or hot air treatment to increase the number of crimps. The crimp state of the tow is, for exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com