Method for cleaning molten non-ferrous metal and its equipment

A technology for non-ferrous metals and purification equipment, which is applied to the purification and refining method of aluminum metal melt. The equipment field designed to realize the purification method can solve problems such as unenvironmental protection, and achieve the effect of saving energy and improving the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

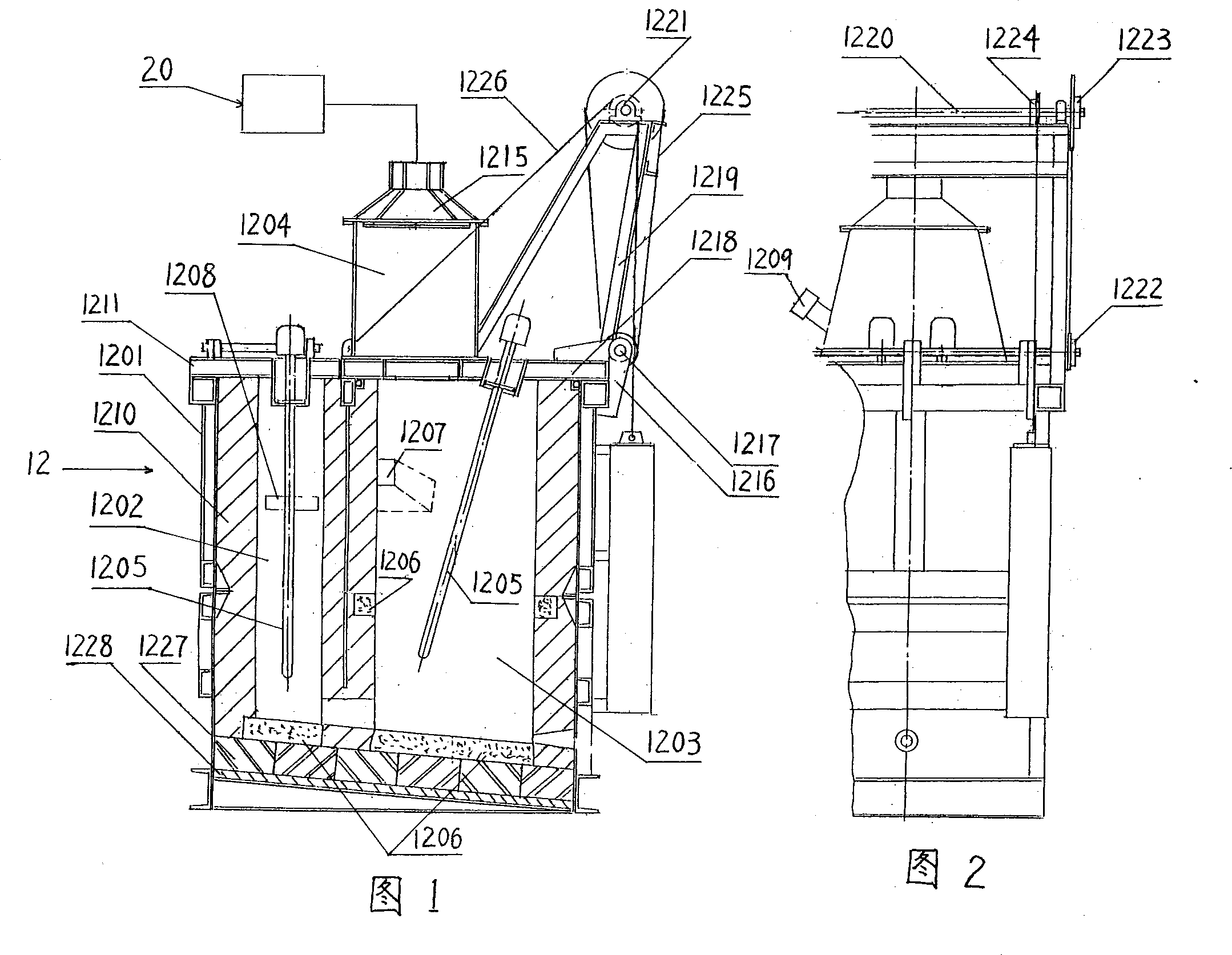

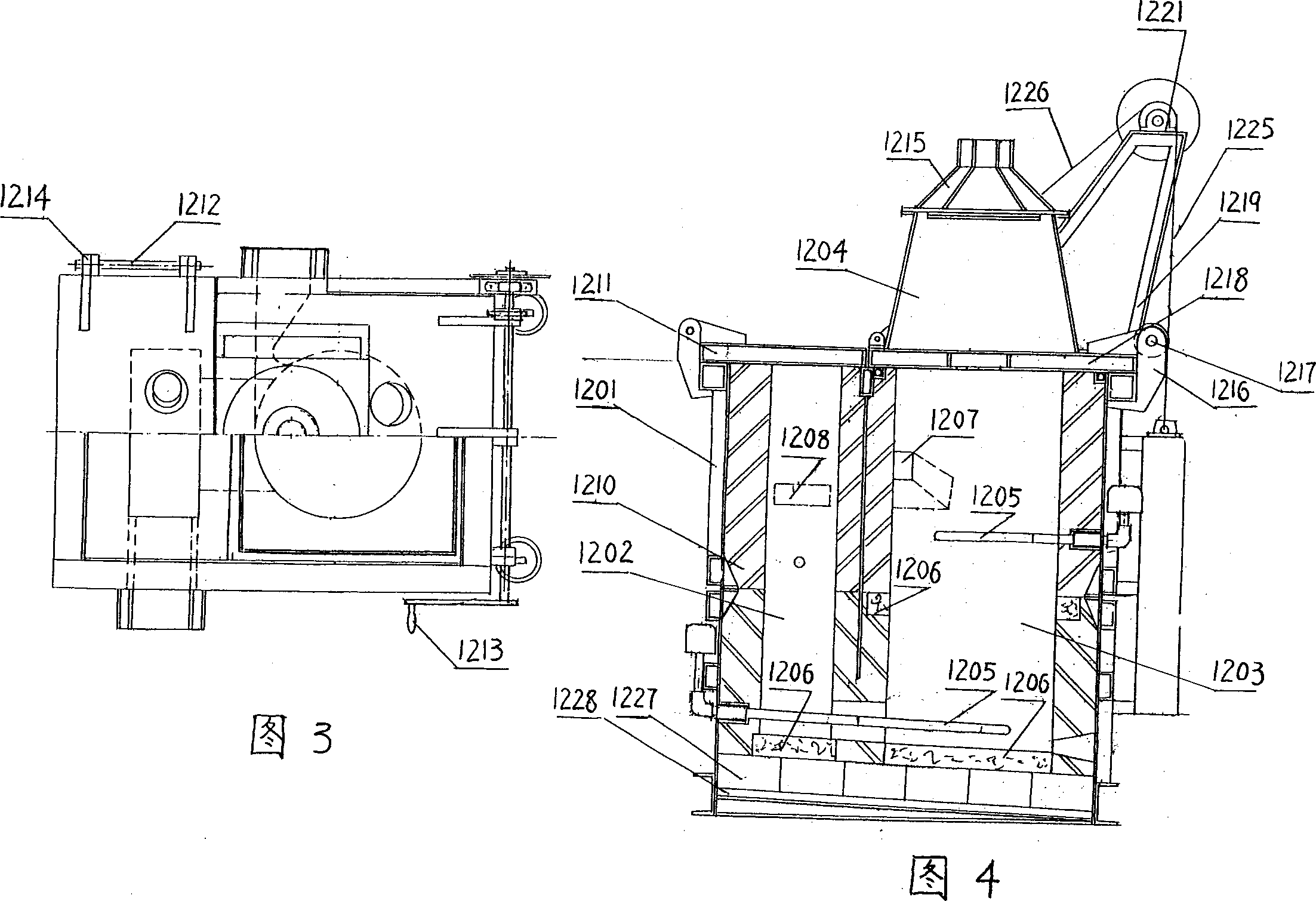

Embodiment 1

[0028] The combination of bubble adsorption (N) and vacuum negative pressure (V) of the purified gas to produce an efficient and environmentally friendly purification function is the technical basis and core of the present invention, and is also a technical feature of the present invention that is different from other types of purification methods.

[0029] Generally, the treatment chamber of the purification equipment for bubble adsorption is closed or semi-closed. Therefore, when the purification bubble rises from the bottom, it absorbs impurities in the aluminum liquid, including hydrogen and oxidation slag, floats out of the liquid surface, and enters the top space of the treatment chamber. , will gather there, and will soon form a saturated state and generate pressure, which will form resistance to the impurities that continue to escape from the molten aluminum, and the concentration of impurities in the upper layer of molten aluminum will also increase, which will inevitab...

Embodiment 2

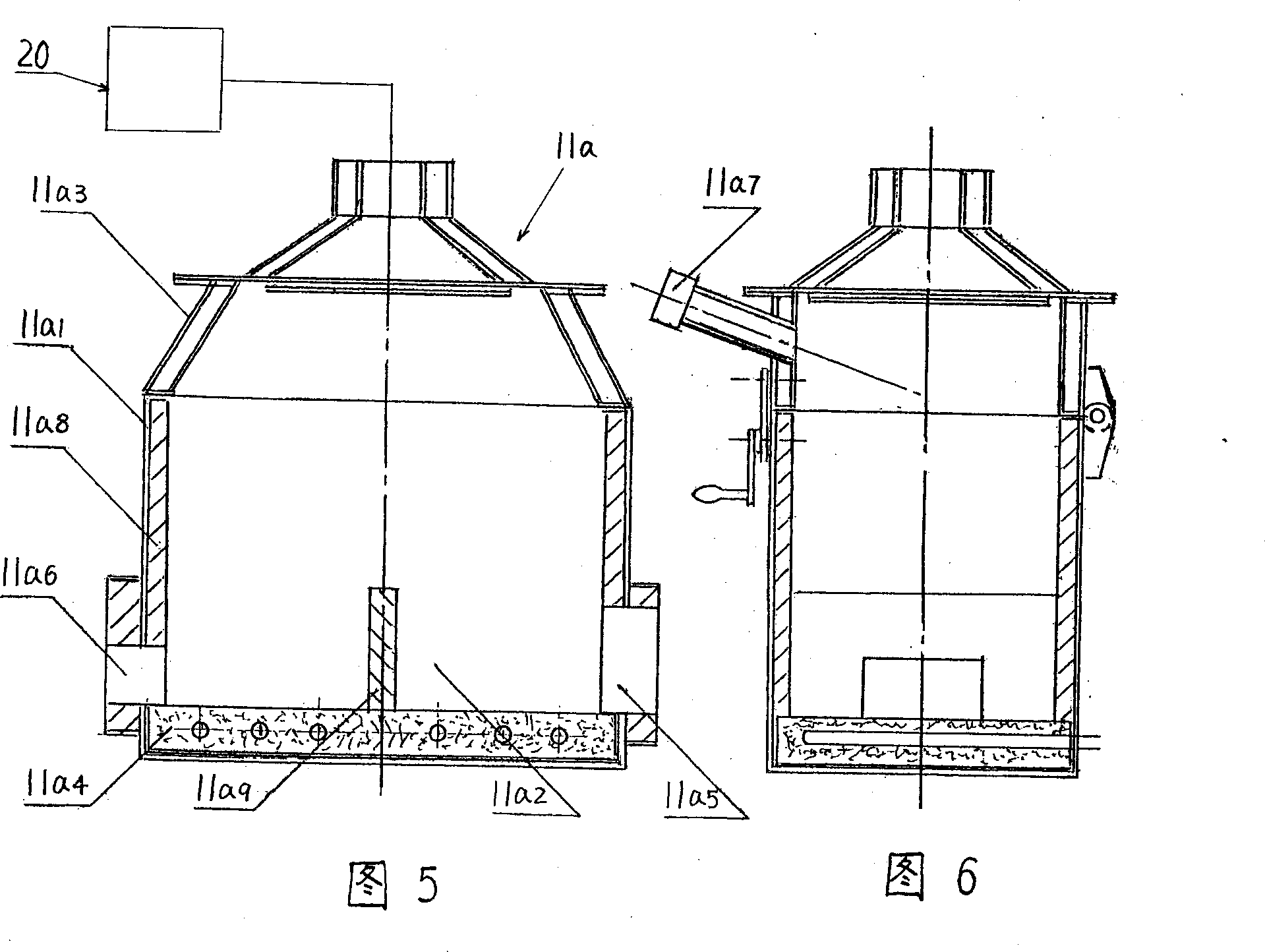

[0039] The equipment that realizes purification method of the present invention can also be Fig. 5~ Figure 7 The shown single-chamber structure, as shown in Figure 5 and Figure 6, the single-chamber structure non-ferrous metal purification device 11a is provided with a shell 11a 1 , a refractory plate 11a is pasted on the inner wall of the shell 8 , the space inside the shell constitutes the processing chamber 11a 2 , the upper part of the shell is equipped with a vacuum cover 11a connected with the vacuum machine 3 , the bottom of the shell is equipped with a purified gas diffuser plate 11a 4 , the bottom of the shell is equipped with gate 11a 9 , with molten metal inlets 11a on both sides 5 And molten metal outlet 11a 6 , a sight glass 11a is installed on the vacuum cover 7 .

[0040] This device is a relatively simple device used in continuous or semi-continuous casting. If conditions permit, the trough-type NSV device can also add a vortex function. If the conditi...

Embodiment 3

[0045] Furthermore, the equipment for realizing the purification method of the present invention can also be Figure 8 In the shown chamberless structure, a vacuum cover 121 and a peep mirror 122 are provided on the melting furnace 124 top, and a bell-shaped purging gas diffusion pipe 123 is housed in the furnace.

[0046] The device is directly used on various furnaces such as electric induction furnaces or holding furnaces, and the cover is equipped with a bell-shaped purification gas diffusion pipe to spray nitrogen (N) gas; various types of rotating rotors can also be used to improve degassing efficiency. There is no need to install an electric heating rod, because the stove itself has a heating function (equivalent to an external heating type). The vacuum cover (V) is necessary so that it can be combined with nitrogen bubbles to purify the molten metal.

[0047] Like the device 11b, this device is not limited by the processing time, and the processing effect is relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com