Device for clearing surface of roller

A technology of rollers and brush rollers is applied in the field of devices on the surface of rotating rollers, which can solve problems such as hindering the long-term use of the machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Description of preferred embodiments

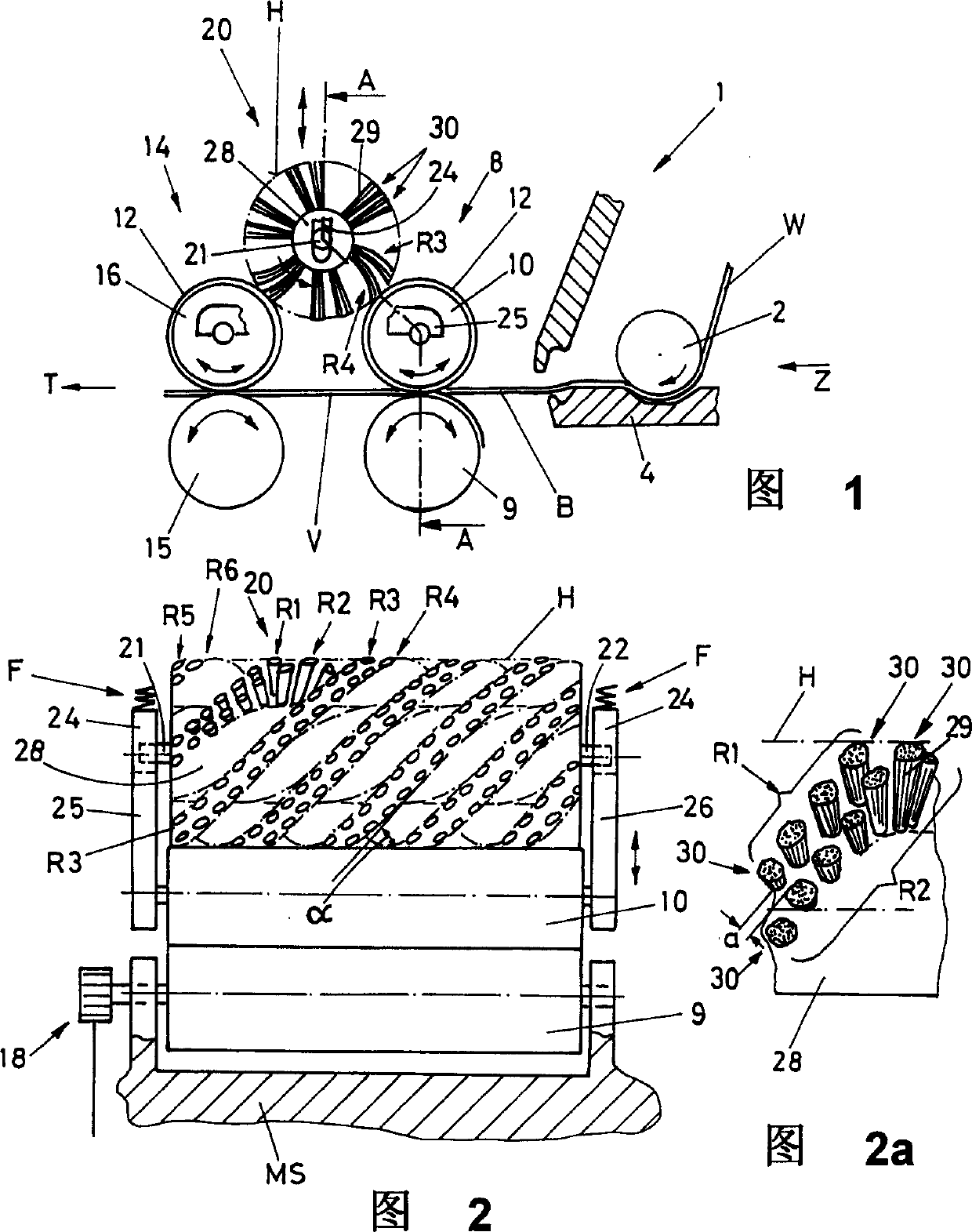

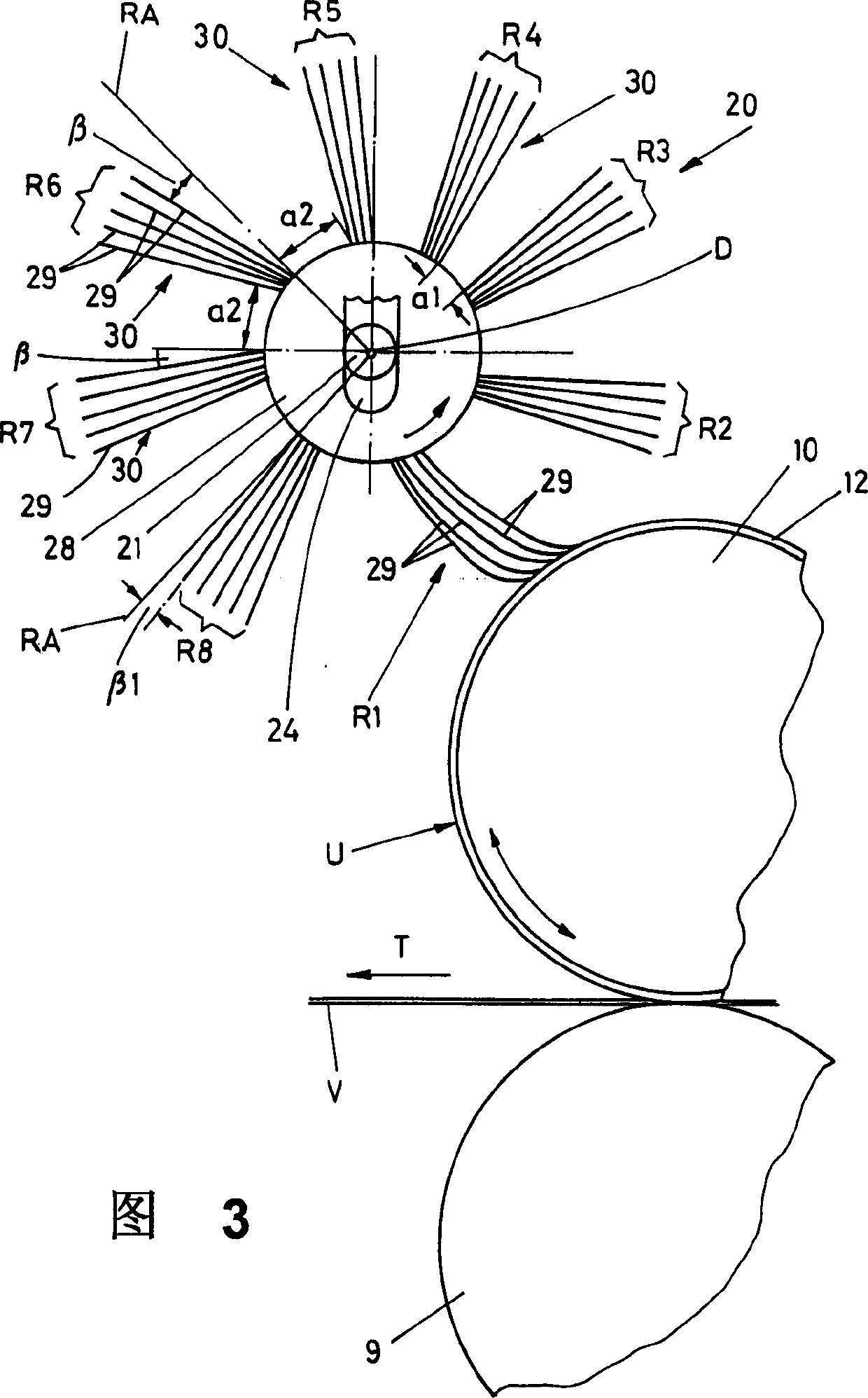

[0027] FIG. 1 shows a partial view of a nipper assembly 1 with a feed roller 2 attached. A degreased cotton W unwound from the final lap (not shown) passes through the feed roller 2 cooperating with the feed plate (not shown in detail) of the lower nipper 4 by the nipper movement Z along the separation roller pair 8 direction conveying. The detaching roller pair 8 here comprises a driven moving roller 9 and a pressure roller 10 which is pressed in the direction of the roller 9 by means of a loading device schematically indicated by a spring F ( FIG. 2 ). The pressure roller 10 is covered with a rubber layer 12 for this purpose. Behind the pair of rollers 8 there is a further pair of rollers 14 which comprises a fixedly mounted driven roller 15 and a pressure roller 16 . The pressing roller 16 is pressed by the same loading device in the direction of the roller 15 and likewise has a rubber layer 12 . Rollers 9 and 15 are driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com