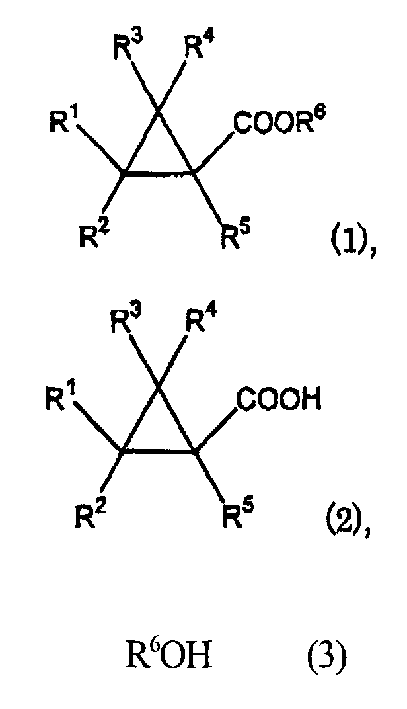

Process for prepn. of cyclopropane formic ether

A technology of cyclopropane formic acid and alkyl, which is applied in the field of preparing cyclopropane formic acid ester, and can solve problems such as ineffective industrial production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Add 0.43 gram of 2,2-dimethyl-3-(2-methyl-1-propenyl) cyclopropanecarboxylic acid (E / Z=80 / 20) in 10 milliliters test tube type reactor, 0.50 gram 3-benzene oxybenzyl alcohol, 5.8 mg of zirconium tetrachloride, and 5 mL of xylene. The reactor was equipped with a Dean-Stark trap and a condenser, and the reaction mixture was stirred at 145°C under reflux for 8 hours while separating and collecting the water produced in the reaction as a by-product in the trap . The reaction mixture thereof was analyzed by gas chromatography, and it was found that 2,2-dimethyl-3-(2-methyl- (3-phenoxyphenyl)methyl 1-propenyl)cyclopropanecarboxylate.

Embodiment 2

[0068] A reaction was carried out in a manner similar to that of Example 1, except that 9.4 mg of a complex of zirconium tetrachloride and 2-tetrahydrofuran was added instead of 5.8 mg of zirconium tetrachloride in Example 1.

[0069] The reaction mixture thereof was analyzed by gas chromatography, and it was found that 2,2-dimethyl-3-(2-methyl- (3-phenoxyphenyl)methyl 1-propenyl)cyclopropanecarboxylate.

Embodiment 3

[0071] The reaction was carried out in a similar manner to Example 1, except that 7.3 mg of zirconocene dichloride was added instead of 5.8 mg of zirconium tetrachloride in Example 1.

[0072] The reaction mixture thereof was analyzed by gas chromatography, and it was found that 2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylic acid was obtained in a yield of 97% (selectivity: 98%) based on alcohol species (3-phenoxyphenyl)methyl ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com