Completely closed piston and piston ring assembly

A piston ring, fully enclosed technology, applied in the direction of piston rings, pistons, engine components, etc., can solve problems such as complex structures, and achieve the effects of saving lubricating oil, good sealing effect, and fuel saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

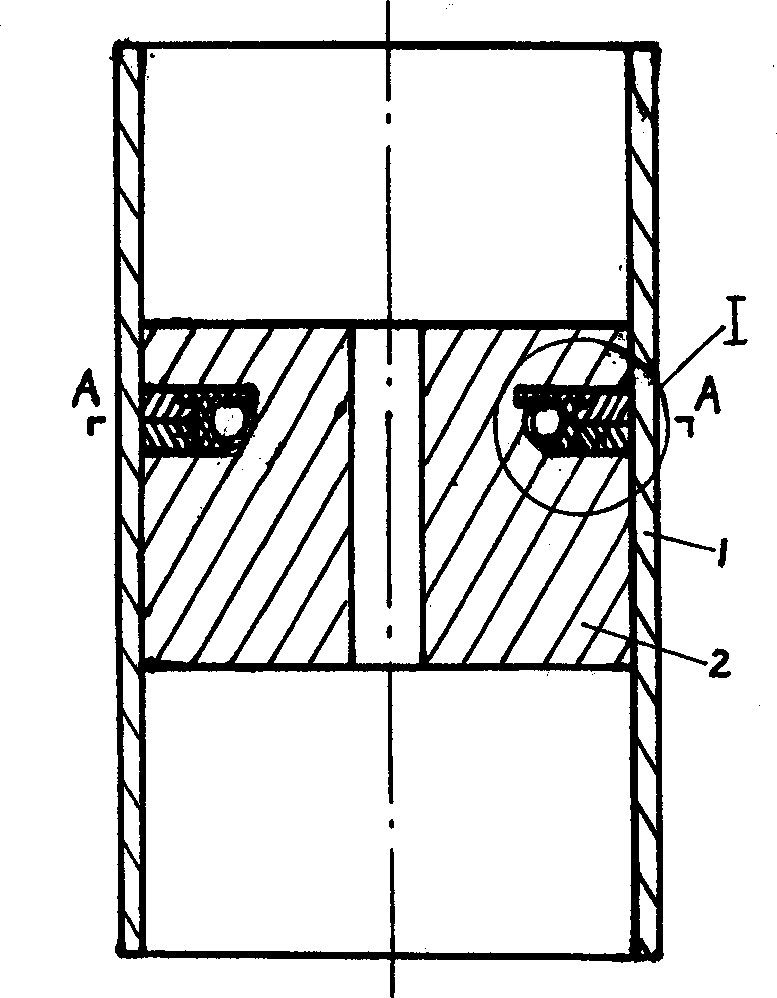

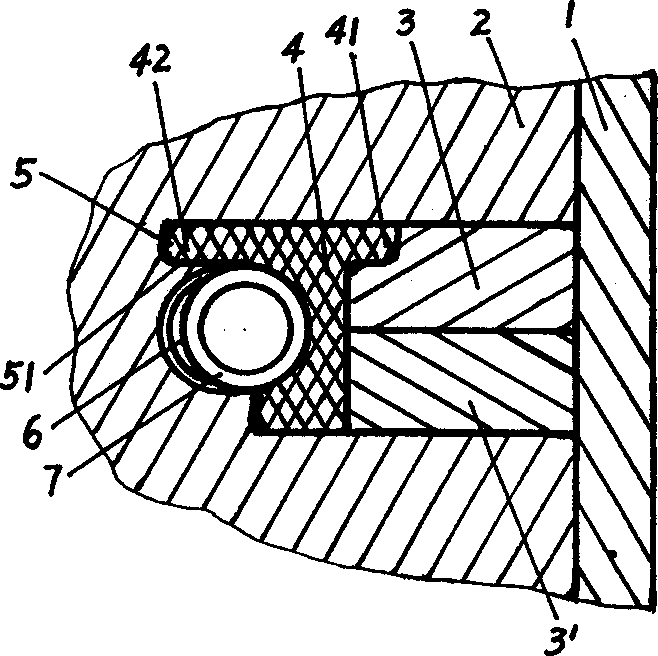

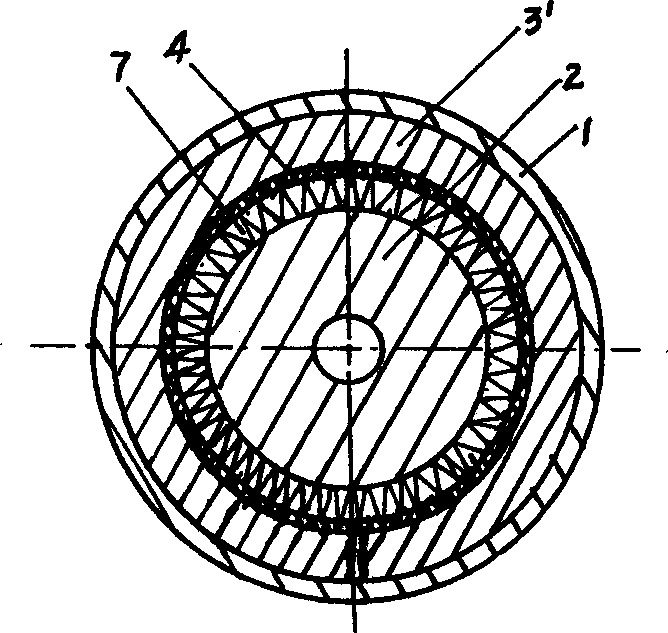

[0018] Such as figure 1 , figure 2 , image 3 As shown, the first embodiment of the present invention is that a piston 2, two gas rings 3 and 3' with staggered openings, an elastic ring 4 and a spring 7 are installed in the cylinder 1. Two gas rings 3 and 3' with staggered openings are arranged in the gas ring groove of piston 2, and elastic rings 4 are installed on the radially inner end faces of the two gas rings 3 and 3', and the width of the elastic ring is twice as large as that of the gas ring. corresponding to the width. The gas ring groove bottom surface of the above-mentioned piston has an annular groove 5 along one side wall of the gas ring groove, and the side wall 51 of the non-gas ring groove side wall of the annular groove 5 is parallel to the gas ring groove side wall. The elastic ring 4 is a closed ring body without an opening, and the radially inner end surface of the elastic ring 4 has a radially protruding axial end that enters the above-mentioned annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com