Resin relief plate for forming film

A technology of resin and film, which is applied in the field of resin letterpress for film formation, which can solve problems such as poor gap, uneven thickness, display color spots, etc., and achieve the effect of suppressing marginal phenomenon and uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0036] Examples 1-10, Comparative Examples 1-11

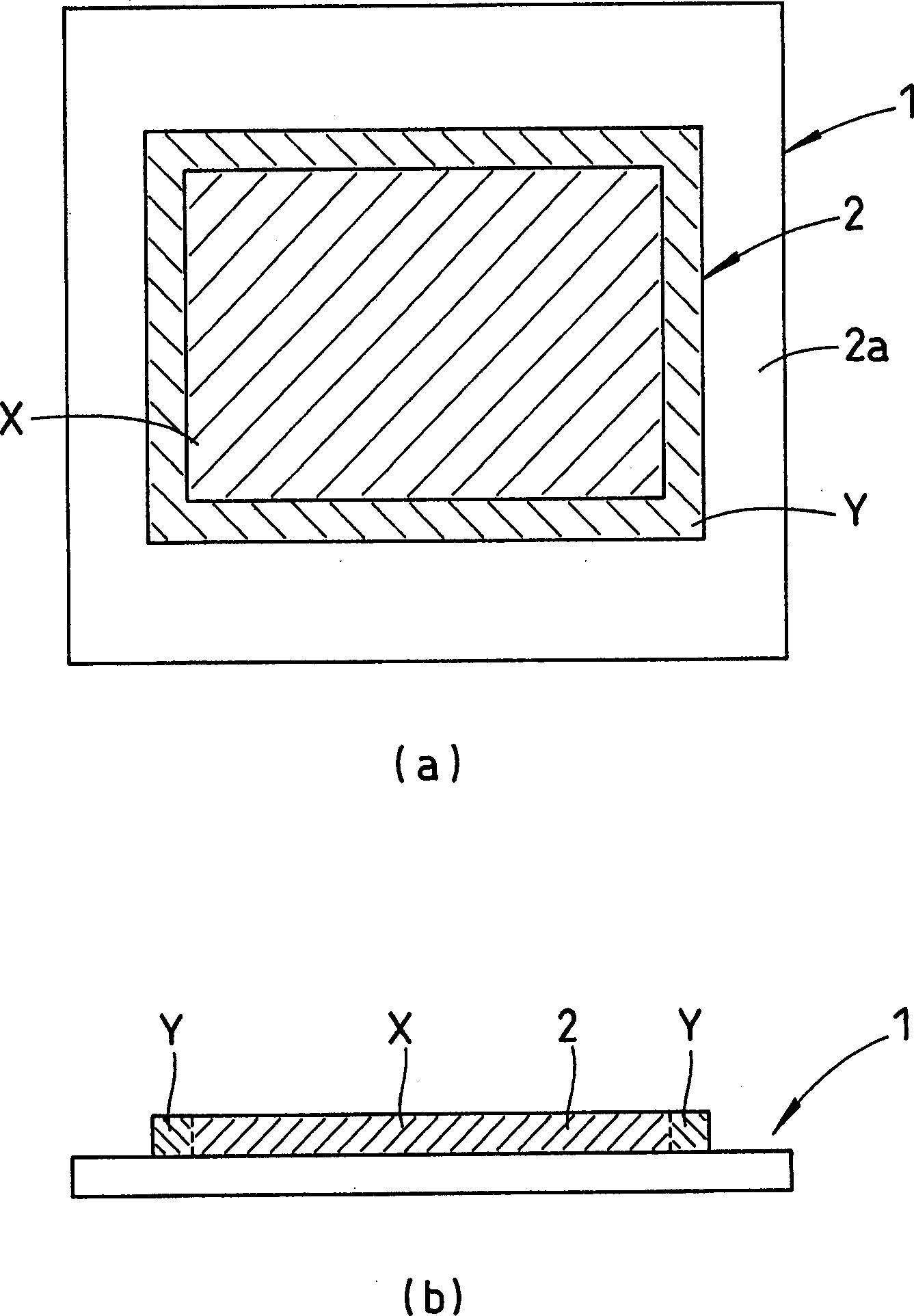

[0037] Production of Resin Letterpress

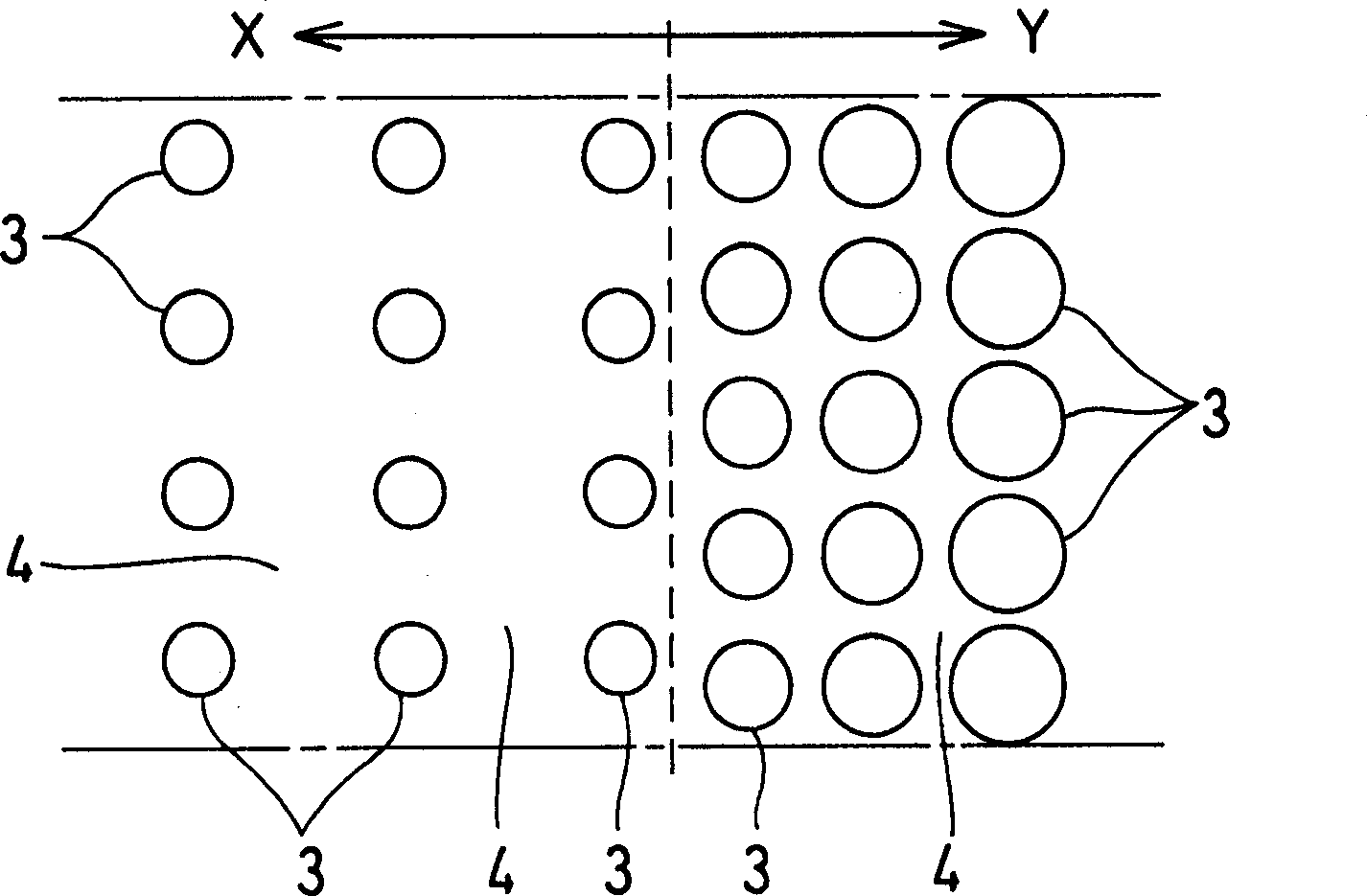

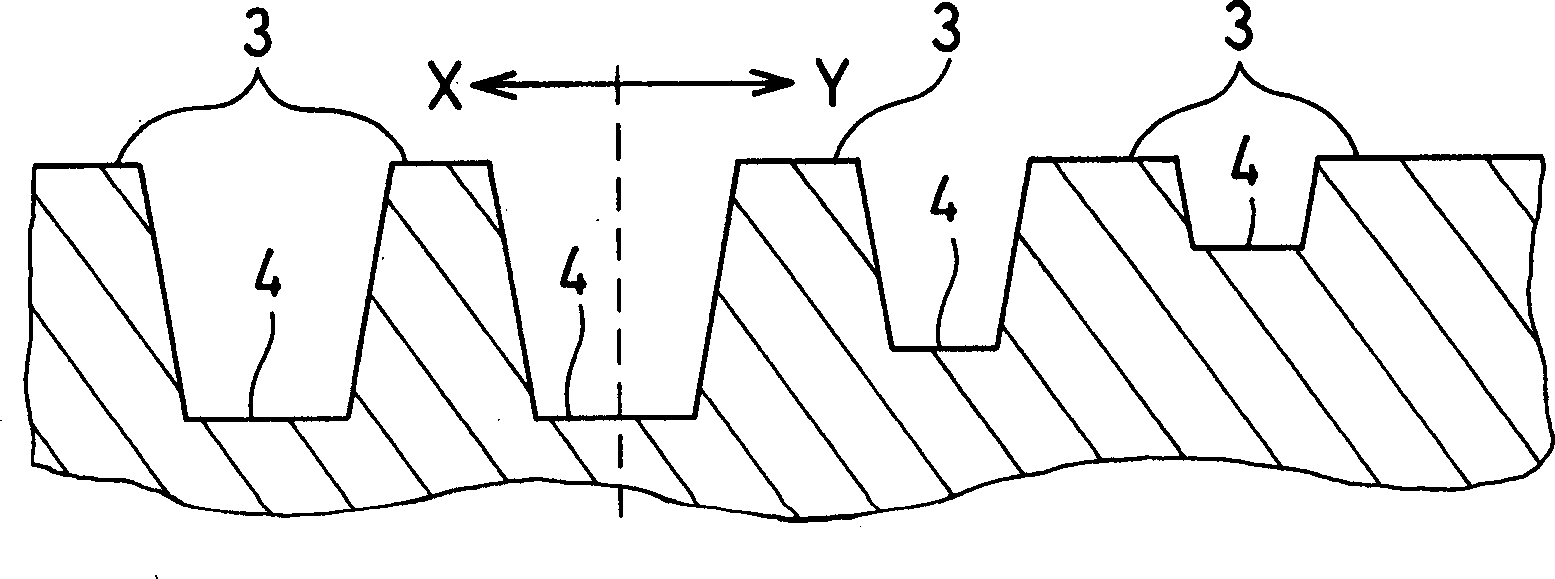

[0038] First, a glass plate with a thickness of 10 mm is prepared. A negative film was placed thereon, and a liquid photocurable resin (manufactured by Asahi Kasei Co., Ltd., APR) was applied to a certain thickness on the negative film with a doctor blade coater. After that, the base film was placed on the surface of the above-mentioned photocurable resin. Then, light is irradiated through the base film, and then light is irradiated through the above-mentioned negative film to form protrusions for printing, and at the same time, a plurality of microprotrusions and grooves formed by the microprotrusions are formed on the protrusions for printing. After that, the uncured resin is washed and removed, dried and exposed to light (post-exposure) to produce a resin relief.

[0039] In addition, the negative-type film used in the production of the above-mentioned resin relief is produced by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com