Acid capped amine catalyst for preparing polyurethane

A technology of catalysts and blocked amines, applied in the direction of organic chemistry, can solve the problems of foam plastic collapse, poor foam plastic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

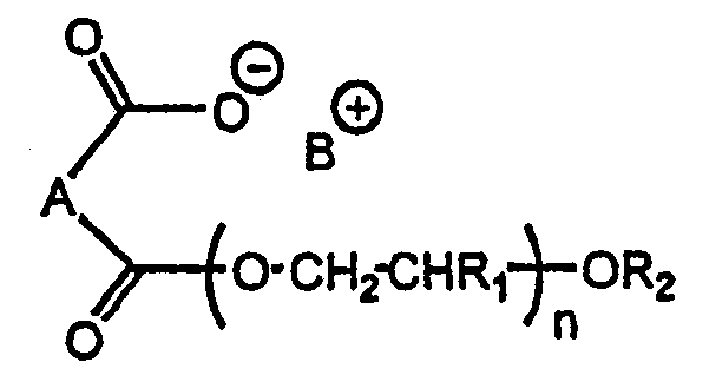

Method used

Image

Examples

Embodiment 1

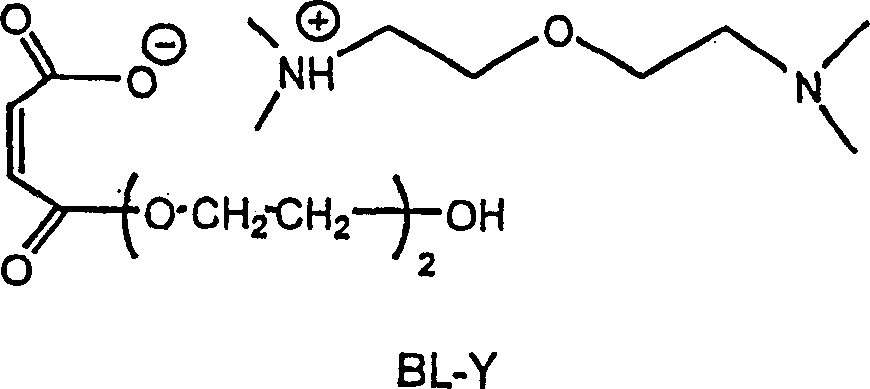

[0033] Acid-terminated BDMAEE catalysts were prepared using the following ingredients:

[0034] BDMAEE: 37.0 p.b.w. 0.23 mol

[0035] ·HO(CH 2 CH 2 O) 2 H: 28.8p.b.w. 0.27mol

[0036] · Phthalic anhydride 34.2p.b.w. 0.23mol

[0037] The alcohol was heated to 100°C with stirring and phthalic anhydride was added. After all the phthalic anhydride had dissolved, the reaction mixture was cooled to 50-70°C and the amine (BDMAEE) was added slowly. The solution was maintained at about 60°C for one hour to complete the reaction.

[0038] Table 1 shows the MDI flex molding control Formulation A ("High Density Formulation") used to evaluate the performance of the new acid-terminated amine catalyst.

[0039] components

[0040] pbw = parts by weight

[0041] * DABCO DC 2585 - Silicone Surfactant supplied by Air Products and Chemicals, Inc

[0042] ** DABCO 33LV - 33% by weight solution of triethylenediamine in dipropylene glycol supplied by Air Products and Chemical...

Embodiment 2

[0053] The following MDI flex molding control formulation (B) ("Low Density Formulation") was used to evaluate the performance of BL-X.

[0054] Table 4

[0055] Polyether polyol (OH#=28)

[0056] BL-X was used as the acid-terminated blowing catalyst. Use levels with the same BDMAEE content were chosen for all three catalysts. The results are listed in Table 5.

[0057] test

[0058] The results of Experiment 2 indicated that BL-X provided a longer onset time compared to the non-capped BDMAEE based DABCO BL11. Additionally, BL-X provided a longer onset time than a competing delayed blow catalyst (NIAX A 400). The demold time was determined as previously described. The demold times for trials 1-3 were all comparable based on the hand-mixed foam sheets. Also, the more delayed onset time with BL-X did not affect cure time.

[0059] Element

[0060] Table 6

[0061] test

[...

Embodiment 4

[0064] Corrosion test

[0065] For the determination of corrosivity, stainless steel metal blades were stored at 65°C for 2 weeks with BL-X and with a competitive capped blowing catalyst (NIAX A 400). The weight of the leaves before and after storage was determined. The loss of its amount is considered a measure of the corrosivity of the acid-terminated blowing catalyst.

[0066] Table 7

[0067] catalyst

weight before storage

mg

weight after storage

mg

mg

%

BL-X

836.3

833.7

2.6

0

NIAX A 400

771.8

765.3

6.5

1

[0068] The results in Table 7 show that BL-X does not corrode. Compared with NIAX A 400, its performance is slightly better.

[0069] Result (embodiment 1-4) summary

[0070] These examples show that use of the novel acid-blocked amine catalysts provides significantly improved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com